46

8. Daily Inspection and Maintenance

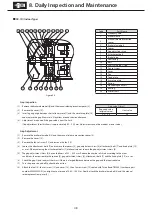

8-7 Brake Maintenance and Inspection

DANGER

- Do not handle the unit when cables are live. Be sure to turn off the power when operating on the unit; otherwise, electric shock

may result.

- When using for lifting, do not release the brake while a load is suspended; otherwise it could fall, causing an accident.

- Do not operate the machine while the brake is released by the manual brake release bolt; otherwise, falling, going out of

control, or damage to the equipment may result.

- Before operation turn power on and off to check brake action; otherwise falling or running out of control could occur.

- Do not bring water or oils in contact with the brake. Brake torque degradation could cause falling or running out of control.

CAUTION

- After gap inspection and adjustment do not operate with the fan cover removed. otherwise loose clothing may became caught

in these rotating parts and cause serious injury or death.

- Changing brake linings requires experience. Consult with the nearest authorized service station.

Given normal operation conditions, brake mechanical lifetime is quite long at 2 million times (1 million times for FB-30, ESB-250

and ESB-250-2). These conditions include the moment of inertia for the load being no greater than the moment of inertia for the

brakemotor. However, please periodically inspect the brake gap (G). The brake lining wears after long hours of running time, mak-

ing it impossible for the brake to release. When 2 million times is exceeded (1 million times for FB-30, ESB-250 and ESB-250-2), wear

and damage to mechanical parts may cause dropping or overdrive problems.

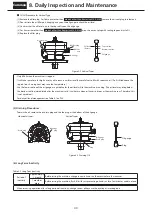

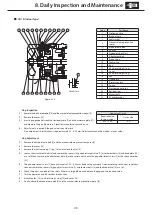

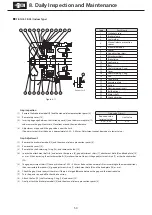

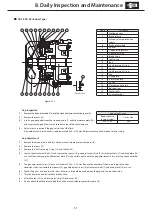

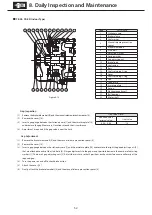

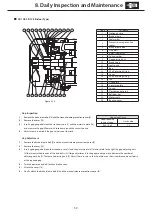

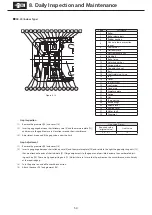

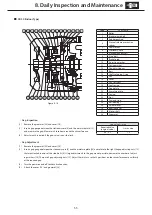

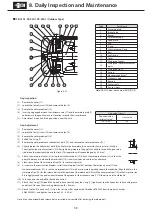

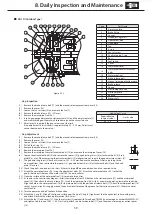

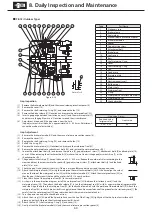

8-8 Brake Construction and Gap Inspection and Adjustment

- The brake is spring activated (power-off type).

- The brake lining wears after long hours of operating the brake, making it impossible for the brake to release. Therefore please

periodically inspect the brake gap (G).

- If on inspection the gap is close to the limit, adjust the gap.

- In FB-1E – FB-4E a shock absorber is inserted between the stationary core and the armature plate to reduce the noise that results from

the braking action.

When inspecting be careful that the gap gauge, other measuring tool or anything else does not damage the shock absorber or cause

it to fall out.

There is danger that if the shock absorber is damaged or falls out, brake noise will increase and the brake will not function properly.

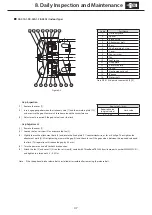

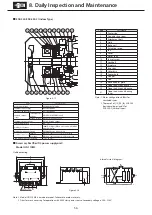

Table 8-17 Pages Containing Information on Brake Construction and Gap Inspection and Adjustment

Brake type

Indoor

Outdoor

FB-01A1, FB-02A1, FB-05A1

P47

P58

FB-1D

P48

P59

FB-1E

P49

P60

FB-1HE, FB-2E

P50

P61

FB-3E, FB-4E

P51

P62

FB-5E, FB-8E

P52

P63

FB-10E, FB-15E

P53

P64

FB-20

P54

P65

FB-30

P55

P66

ESB-250, ESB-250-2

P56

P67