Cleaving the fiber

An example shows use of Sumitomo FC-6M fiber cleaver. Please read the FC-6M

operation manual before use. If you use another fiber cleaver, please refer to its

operation manual.

Standard cleave length: 10mm

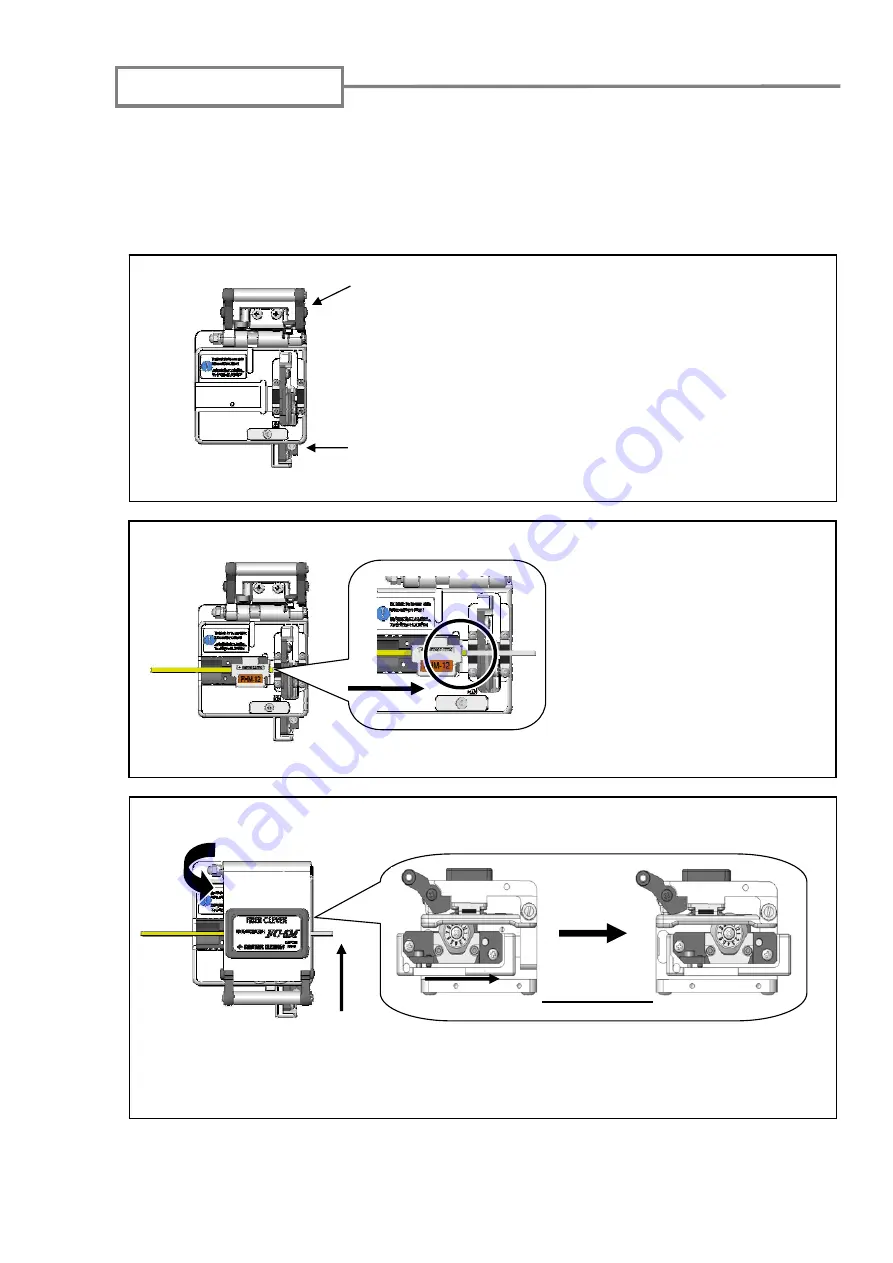

1-1: Open the coating clamp lid and the top

clamp lever. The blade carriage should

be in the forward position.

Blade carriage

1:

2:

2-1: Place the fiber holder in the

FC-6M. (Touch the edge of

the fiber holder against the

FC-6M.)

* Keep the fiber in the fiber

holder after stripping the

fiber coating/cleaning the

bare fiber.

3:

3-1: Lower the top clamp lever. Slide the blade carriage to the rear of the cleaver

as indicated by the arrow.

Cleave the fiber

Top clamp lever

19

Summary of Contents for TYPE-66M12

Page 67: ...57...