Arc test procedure

The fusion splicer has a built-in Arc test feature that should be used to ensure consistent

high-quality splices with low splice losses. Performing an arc test automatically adjusts

the arc power and position to compensate for environmental conditions, electrode wear

and the melting characteristics of the fiber types in use.

.

Situations that should prompt an arc test are:

•Initial splicing set-up

•Changing fiber types

•Extreme changes in temperatures, humidity or air pressure

•Poor splice performance

22

•After electrode replacement

1: Strip the coatings, clean, cleave and insert the

fibers. (Hereinafter called “prepare the fiber”)

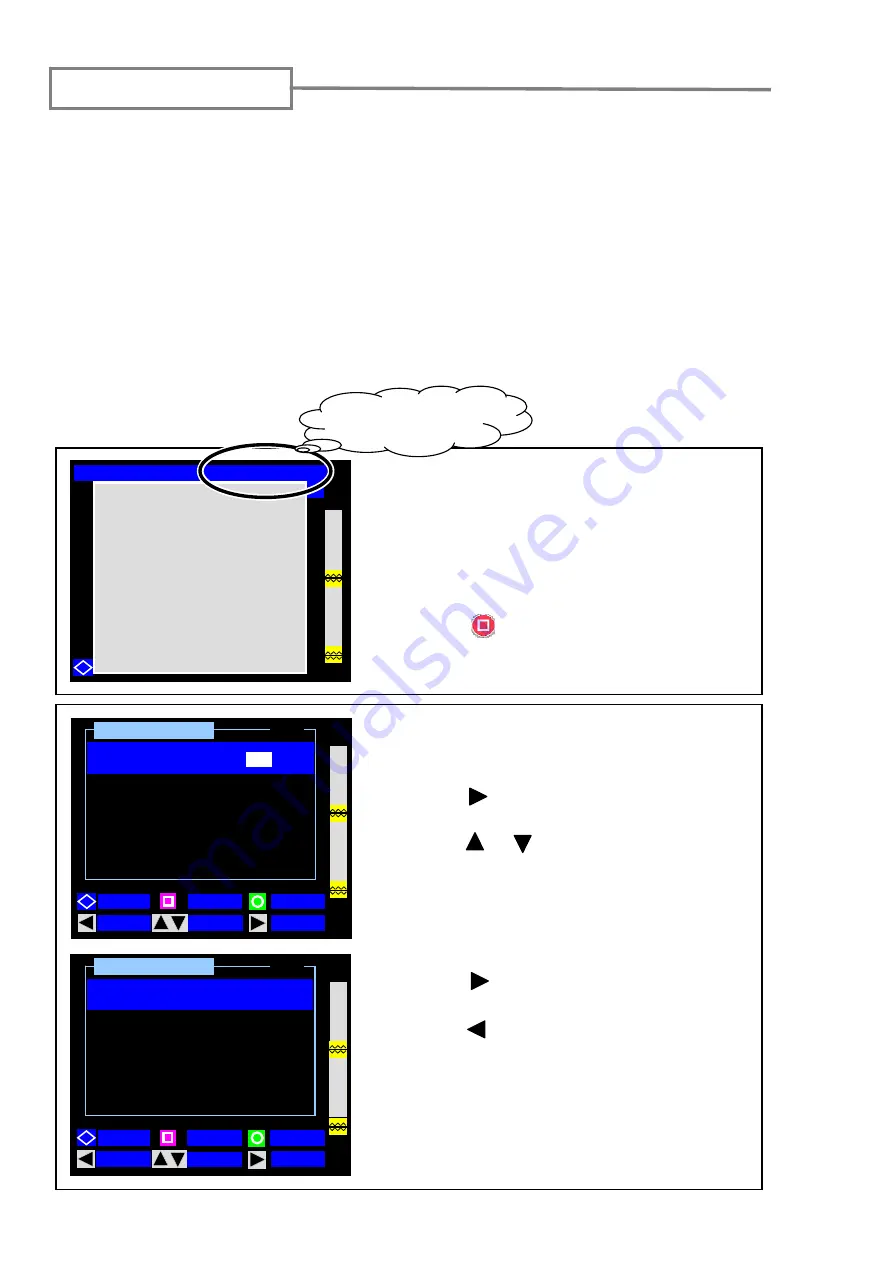

*After initialization, check to see if the displayed

fiber type and protection sleeve type are correct.

(if not, change the settings, referring to page 39.)

2: Press the (CONDITION) key.

3: The “condition setting” screen is displayed.

(“Arc Test” is selected.)

4: Press the (SELECT) key.

“OFF” is highlighted.

5: Press the or key to change to “ON”.

Ready [SM:12c-40mm 12c]

Y

Selected fiber type and

protection sleeve

Condition Setting

Arc Test

1 / 3

Arc Center

[240] dot

[ON]

6: Press the (SELECT) key.

Make sure that “ON” is displayed.

7: Press the (BACK) key.

“Arc Test Ready” screen will be displayed.

Condition Setting

Arc Test

1 / 3

Arc Center

[240] dot

BACK

MOVE

SELECT

PAGE

[

OFF

]

BACK

MOVE

SELECT

PAGE

Summary of Contents for TYPE-66M12

Page 67: ...57...