L3214 Laser Cutter

User’s Manual

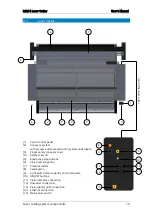

Laser cutting system components

20

2.2

Edge detection unwinder

A motorised unwinder eliminates fabric distortion while cutting by securing a constant and

stable fabric feed onto the cutting bed. As the roll unwinds, a loop is created to relax the

material, reducing distortion, and secure an accurate cut. This loop is kept constant with the

use of the droop sensor or the tension bar.

2.2.1

Safety Information

2.2.1.1

General

The unwinder is used for feeding the laser system with synthetic or natural materials. Using

the unwinder for any other purpose is forbidden. Do not leave any safety covers open when

operating.

WARNING:

Frequent heavy lifting and handling of the rolls of fabric can cause back

injuries. Use appropriate lifting and handling tools or ask assistance to reduce this

risk.

Always turn off the unwinder before opening the safety covers or investigating a malfunction.

Only authorised personal may then switch on the unwinder to investigate the problem.

Always turn off the unwinder before opening the electrics cabinet.

Do not move the unwinder when in operation. Space should be kept clear at both ends of the

unwinder to allow for full travel of the upper frame. Do not lean anything against the unwinder.

WARNING:

There is a risk of injury from being caught or trapped in moving

machine parts. Keep hands, hair, clothing and jewellery away from moving parts.

Do not wear jewellery, loose clothing, scarves or open jackets or shirtsleeves.

2.2.1.2

Residual Risks

The upper frame of the unwinder travels laterally if required to supply the laser cutter with

fabric correctly. The timing of these movements cannot be anticipated, so great care should

be taken when being around the unwinder during operation. Operator presence is not required

during roll feeding. The lateral travel of the feed mechanism has a limited range.

2.2.1.3

Noise

The noise level does not exceed 70 dBA.