L3214 Laser Cutter

User’s Manual

Laser cutting system components

24

2.2.3.3

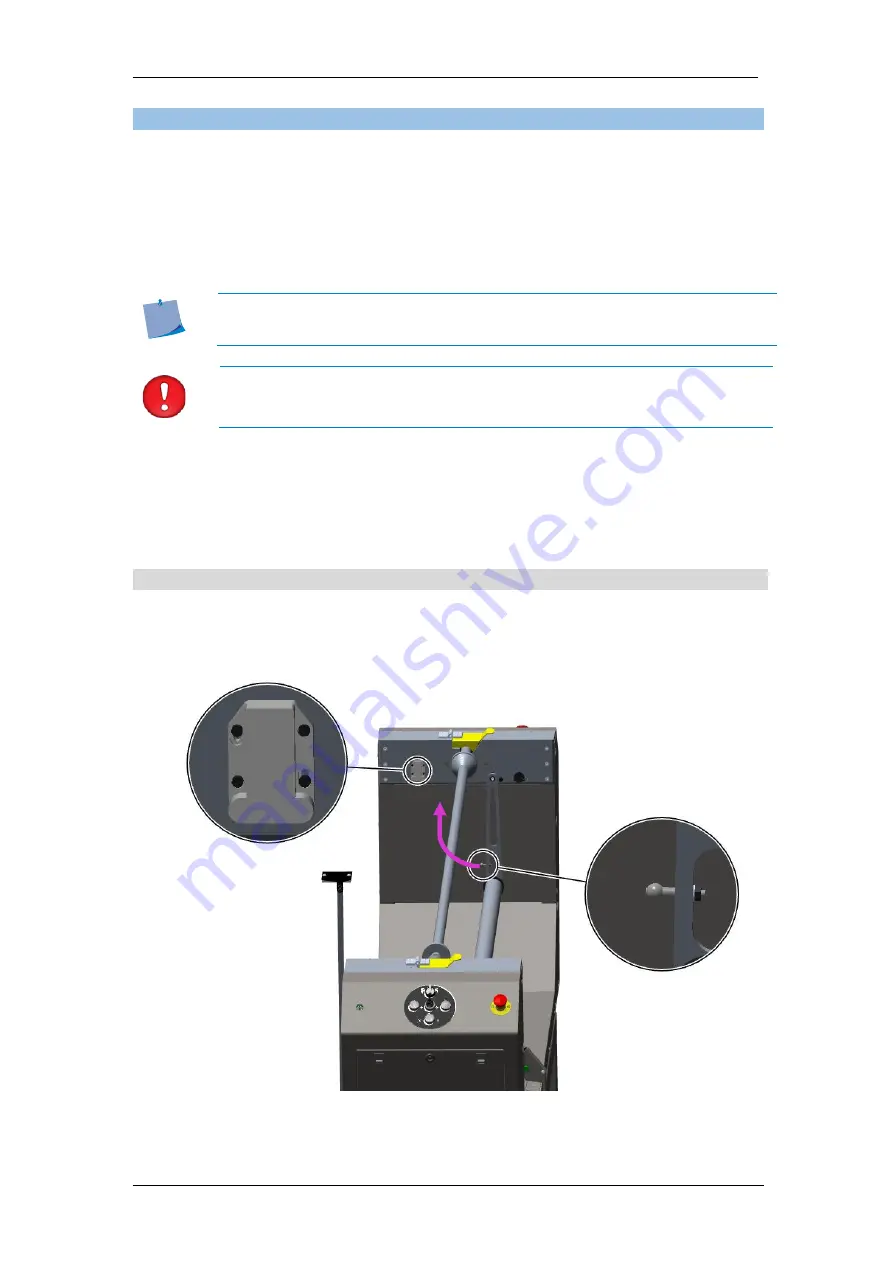

Droop sensor and tension bar

The edge detection unwinder is equipped with both a droop sensor and a tension bar, allowing

you to choose how to keep the loop of relaxed material constant. When the tension bar is being

used, the droop sensor isn’t, and vice versa.

The tension bar swings back and forth according to the material's tension inside the material

loop, to guide the material onto the conveyor without exerting too much tension on it.

NOTE

: The tension bar always exerts a small amount of tension, however slight,

making it less suitable to use with very stretchy materials.

ATTENTION

: Do not lean on the tension bar when it is locked as this may damage

the tension bar and the locking system.

The droop sensor detects when the unwinder has reeled enough slack material to feed the

laser cutter when required.

In any case, as the roll of material unwinds, a loop is created to relax the material, reducing

distortion, and securing an accurate cut.

2.2.3.3.1

Switching from using the tension bar to using the droop sensor

Before using the droop sensor, the tension bar must be locked. To do so, pull the tension bar

upwards and click the tension bar’s locking pin in the bottom of the push latch to secure it.