S CLASS™ 2 cutter

User’s Manual

Contour Cutting

3-22

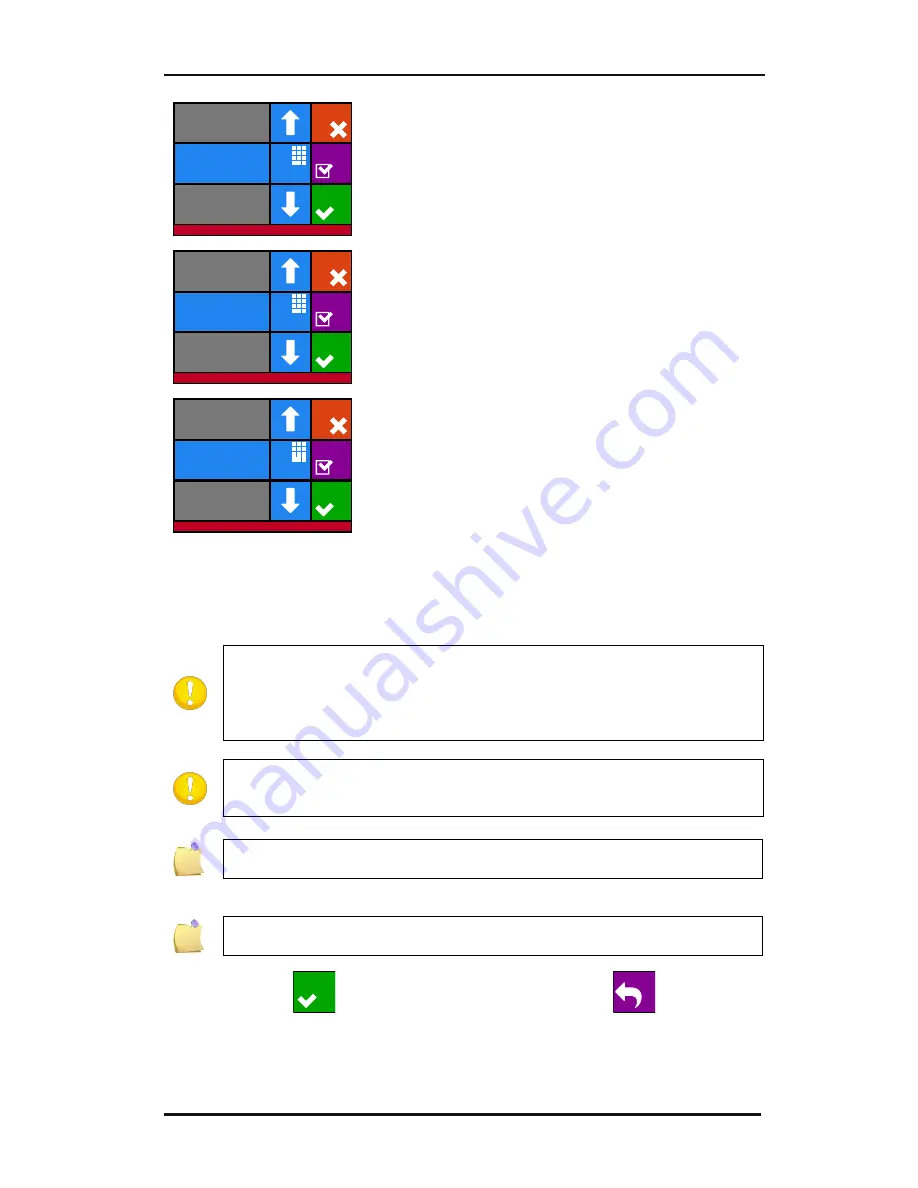

Press the arrows or use

Numpad to change the Full

pressure cut length and

press Apply to confirm.

10mm is a recommended

starting value for the cutting

length at full pressure.

Press the arrows or use

Numpad to change the Flex

pressure and press Apply to

confirm.

50% of the full pressure is a

recommended starting value

for the flex (bridge) pressure.

Press the arrows or use

Numpad to change the Flex

pressure cut length and

press Test to confirm.

1mm is a recommended

starting value for the cutting

length at flex pressure.

The cutter will cut out a test pattern.

4.

Check if the result is satisfactory. If not, change one of the above 4 parameters.

Reducing the velocity can also improve the result. It is never recommended to use

cutting speeds larger than 400mm/s (16 ips) with cutting pressures above 200 gr.

NOTE:

It is not always easy to find the correct balance between cutting deep

enough, making sure the pieces can be taken out easily, and not cutting too

deep, making sure the material keeps its strength while cutting. Sometimes this

balance doesn’t exist, which means that this material can’t be cut through with

satisfactory result.

NOTE:

When cutting through, it is recommended that parallel lines are at least 1

cm away from each other. Otherwise, while cutting the second line, the first line

may come loose and cause trouble.

5.

After that press

to get in the FlexCut menu and then press

Cancel

Numpad

Settings | FlexCut

Old value: 10mm

New value: 10mm

Range: 0.250 ... 250.000

mm

Apply

Test

Cancel

Numpad

Settings | FlexCut

Old value: 80 gr

New value: 80 gr

Range: 0 ... 600 gr

Apply

Test

Cancel

Numpad

Settings | FlexCut

Old value: 1mm

New value: 1mm

Range: 0.250 ... 250.000

mm

Apply

Test

Apply

Back

NOTE:

FlexCut parameters are always metric, regardless the value of the panel

Units parameter.

NOTE:

FlexCut can be set off or on for older types of software that cannot switch

FlexCut on or off. It is recommended to only use the accurate mode.

Summary of Contents for S Class 2 OPOS-CAM

Page 1: ...User s Manual Rev 3b...