S CLASS™ 2 cutter

User’s Manual

Detailed Operation

4-7

4.3.1.5

Knife offset

The

Knife offset

submenu is explained in section 2.2.3.

4.3.1.6

Pouncing gap

The

Pouncing gap

submenu is used to change the pouncing gap (distance between the

holes that are punched in the material by the pouncing tool).

Press the Pouncing gap button, then change the pouncing gap to the desired distance.

Press

to confirm or

to cancel.

4.3.1.7

FlexCut

The

FlexCut

submenu is explained in section 3.5.

However, setting up the cutter for

FlexCutting is not that easy. Follow the next procedure to try and determine usable FlexCut

settings.

1.

Turn out the knife so that the protruding knife tip is longer than the material thickness.

2.

Go to the knife pressure submenu (see section 2.2.2). Increase the knife pressure

gradually and perform the knife pressure test in between until the minimum knife

pressure to cut the material completely through is reached. Then increase this value

with 5-10%. Write down this value.

Apply

Cancel

NOTE:

The pouncing tool is not mounted in the machine at the same place than

the other tools. The pouncing tool should be mounted this way the center of the

pin is located above the black soft pouncing strip.

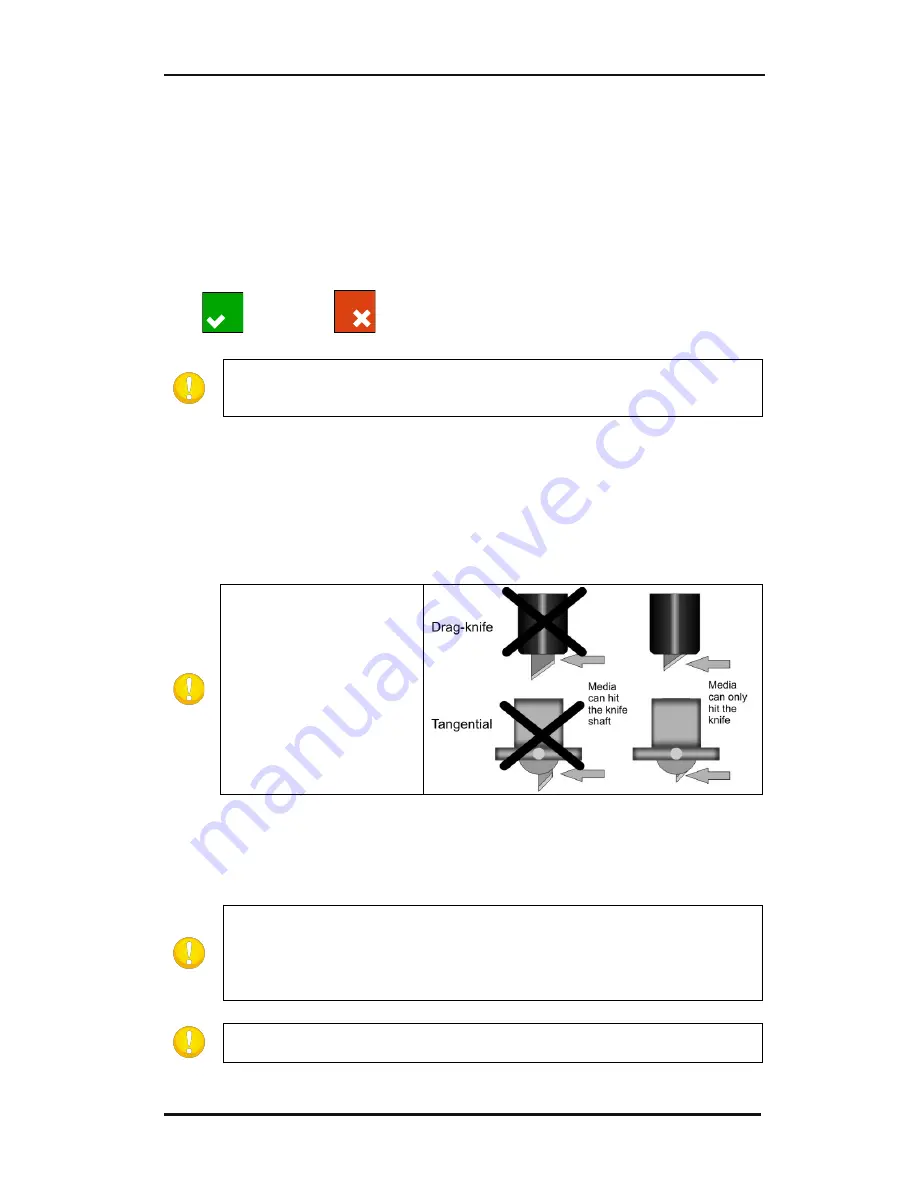

NOTE:

Never turn the knife

so far out, that the media

can hit the knife shaft. Only

the knife edge should get in

contact with the media in

order to avoid media

crashes.

NOTE:

It is discouraged to use brand new knives for cutting through. The

pressure setting and the knife depth of brand new knives change quickly. On

the tangential machines, a double tip knife or double wedge knife is

recommended for cutting through. This knife is more wear resistant and gives

and automatic overcut at the beginning and the end of cut lines.

NOTE:

It is recommended to use cutting speeds of 400mm/s (16 ips) and lower

when the cutting pressure is 200gr or higher.

Summary of Contents for S Class 2 OPOS-CAM

Page 1: ...User s Manual Rev 3b...