S One

User’s Manual

Introduction

1-13

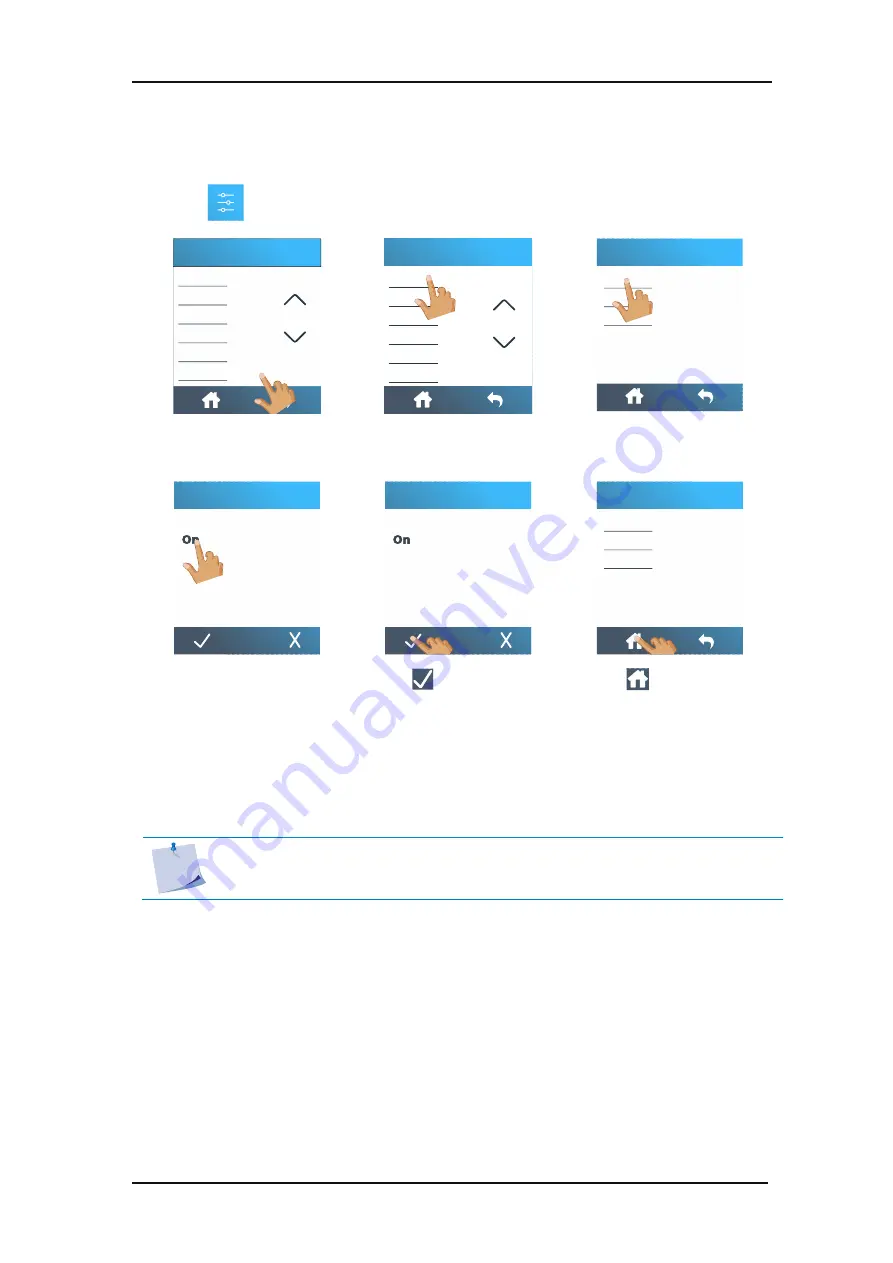

1.

Connect the Ethernet cable and power on the cutter (see section 1.3).

2.

Press

icon.

3.

Scroll down with the arrow

and press Configuration.

4.

Press Ethernet.

5.

Press DHCP.

6.

Press On.

7.

Press

to confirm.

8.

Press

to leave.

9.

Reboot the cutter.

The assigned IP address should now be visible in the status and can be used in the cutting

software.

NOTE:

If the DCHP server is used, then the IP address that is assigned to it can be

changed if the cutter is not used for a time longer than the lease time set in the

DHCP server (check with your IT admin for details).

FlexCut

Tool

Actions

Settings

Calibrations

Configuration

Ethernet

Wi-Fi

USB Port

Language

Menu units

OPOS Parameters

Configuration

Subnet

Ipv4 address

DHCP

Ethernet

Off

DHCP

Off

DHCP

Subnet

Ipv4 address

DHCP

Ethernet

Tool

1.4.2.2

In case the DHCP server is used: