SummaCut cutter

User’s Manual

Contour Cutting

3-5

3.3

Detailed OPOS Operation

3.3.1

Creating the graphic with the markers

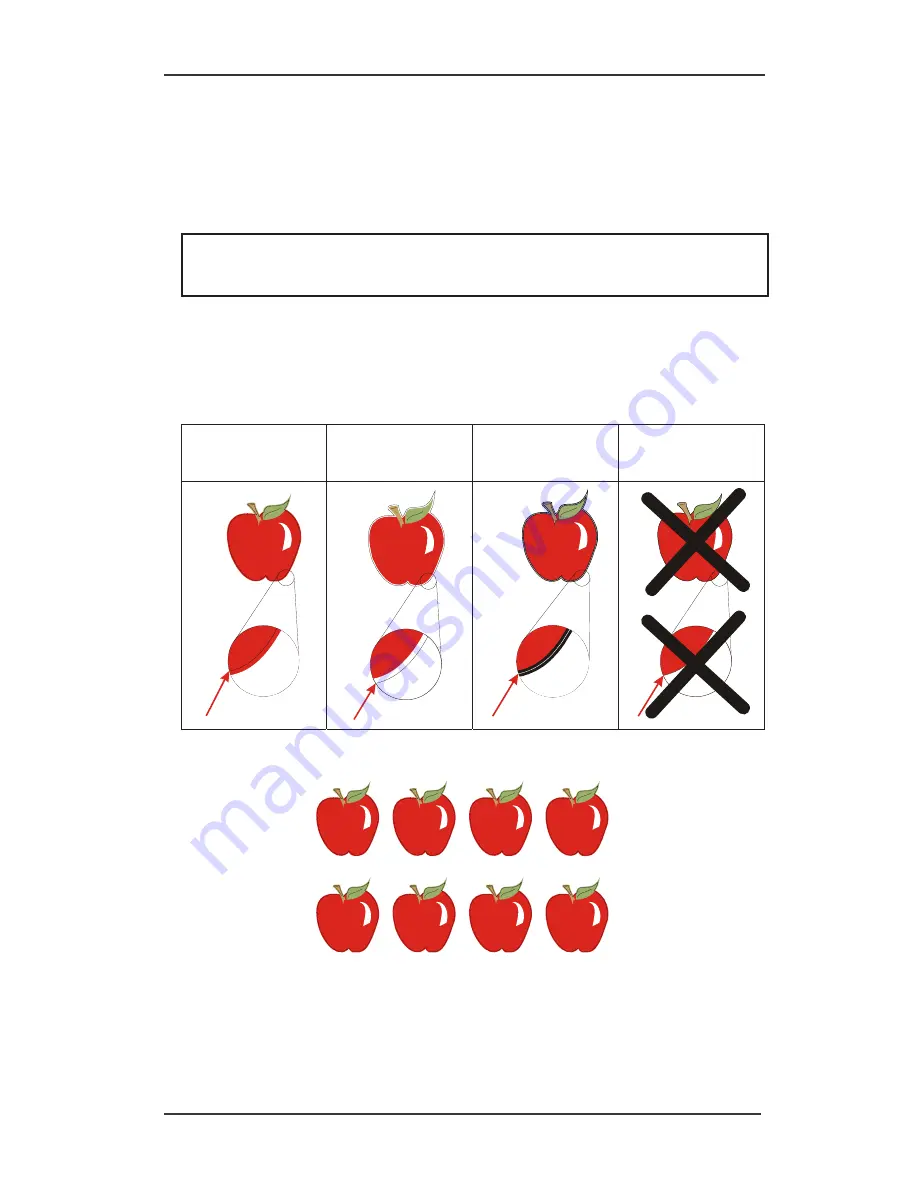

1.

Create the graphic and contour cut line(s). For easier handling, place the contour line(s)

on a different layer.

NOTE:

Do not place contour lines along the edges of graphics or the slightest

movement in the media may result in an unsatisfactory cut. Instead, practice one of the

following techniques:

¾

Place contour lines just inside the graphics (recommended) (1).

¾

Place contour lines outside the graphics (2).

¾

Create thick borders around graphics and place contour lines inside these borders (3).

(1) contour line

inside graphic

recommended

(2) contour line

outside graphic

(3) contour line

inside a thick border

Contour line on

edge of graphic

2.

If necessary, make additional copies of both the graphic and its associated contour.

3.

Insert a marker to represent the Origin. The marker must be a black square. Each of the

marker’s four sides should measure 2mm but must not be less than 1.5mm or more than

10mm. (1=X-size 2=Y-size.)

Summary of Contents for SUMMACUT

Page 1: ...User s Manual Rev 004...