SummaSign Pro SL D-series Cutters

User’s Manual

General Information

1-23

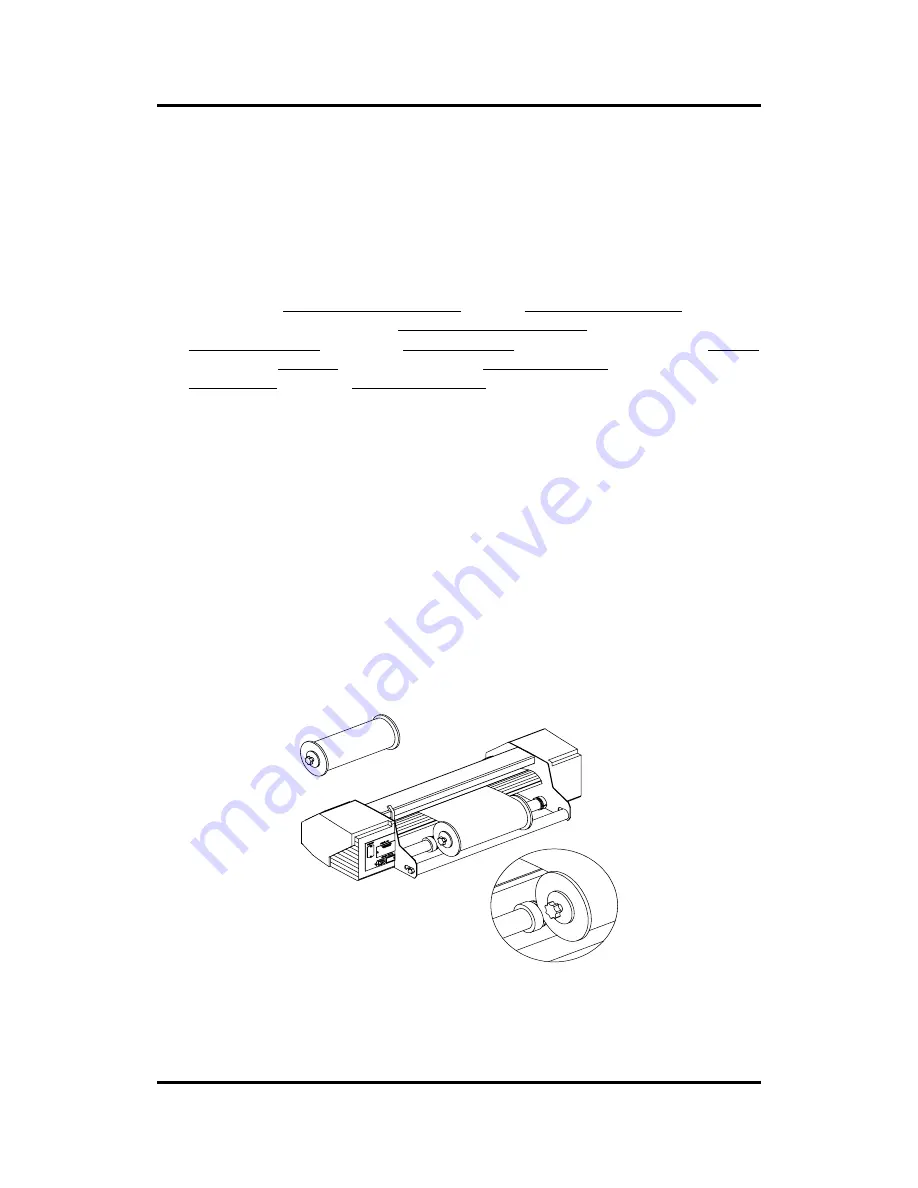

pressed against the roll. Place the flanges on the media support rollers at

the rear of the cutter.

3. Position the flanges on the support rollers at the rear of the cutter.

Slide the two media guides under the media roll so that each flange rests in

the groove in the guide. In this position, the media roll and guides can be

shifted left and right.

Feed the media from the rear of the cutter.

Position the left edge of the media on the leftmost drive sleeve and then

check to see whether the right edge of the media is positioned over the

wide drive sleeve. If it is, the left pinch roller can be positioned in the detent

above the leftmost sleeve. Then, the right pinch roller can be positioned

somewhere over the wide drive sleeve according to the media width. The

right pinch roller can be located anywhere between the two outer detent

positions above the long drive sleeve. This flexibility allows a variety of

media widths to be accommodated.

Should the above procedure fail to work because the media is too narrow

to reach the long drive sleeve, try positioning the left media edge over the

second drive sleeve in from the left. Then position the right media edge

somewhere on the wide drive sleeve. Repeat this process if the media is still

found to be too narrow by locating the left media edge over the third drive

sleeve in from the left. Adjust the right edge of the media as described

above.

Follow the same general procedure when loading media on the wider

models of the D-series Pro SL cutters, which have been provided with

additional sleeves.

If necessary, continue to reposition the media until both edges are

positioned over a drive sleeve.

FIGURE 1-9:

FEEDING ROLL MEDIA USING MEDIA FLANGES