SummaSign Pro SL T-series Cutters

User’s Manual

General Information

1-27

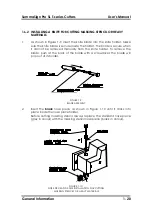

that the left and right edges of the media always rest on sleeves. Position the

pinch rollers so that they are 3 to 15 mm (0.1" to 0.6") in from the edge of the

media.

On the T1010 Pro SL, T1400 Pro SL, and T1600 Pro SL cutters, two, three or more

sleeves may be partly or fully covered, depending on the media width used. To

ensure correct positioning of the pinch rollers, reference marks in the shape of

inverted triangles have been provided on the head guide.

The center low-pressure roller(s) on the T1010 Pro SL, T1400 Pro SL, and T1600 Pro

SL cutters enhance media routing and keep the vinyl flat. Ideally, the roller

should be positioned halfway

between the two outer rollers but always over

one of the drive sleeves.

The center low-pressure roller(s) on the T1010 SL, T1400 SL, and T1600 SL cutters

can be in the raised/disabled position when media narrower than 600 mm is

being cut.

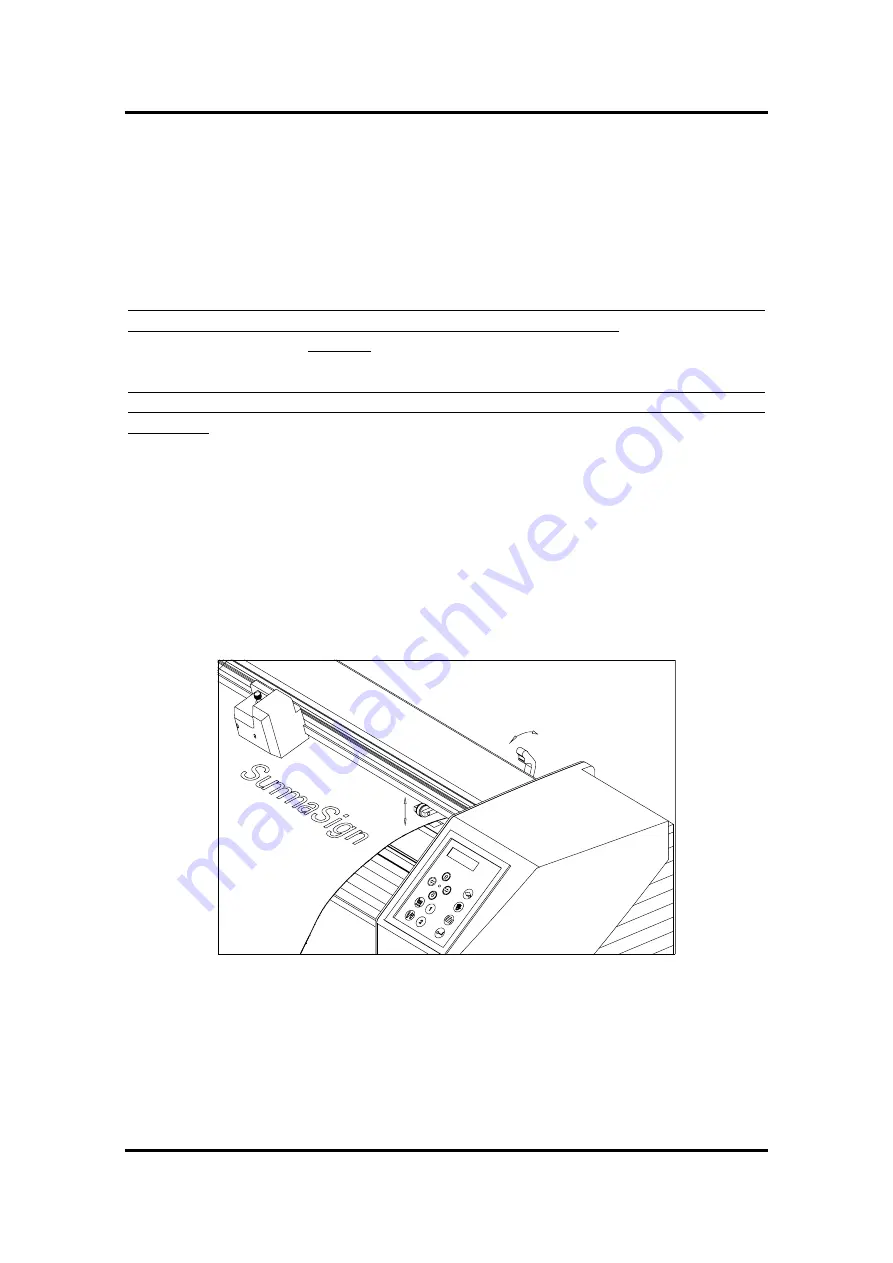

1.7.2

FEEDING AND POSITIONING MEDIA

The following load procedure has been found to be very reliable. Adhere to

these step-by-step instructions when loading media.

Î

To load media, proceed as follows:

1. Raise the pinch rollers by lowering the pinch roller lever located at the back

of the cutter.

FIGURE 1-15:

MEDIA POSITIONING

2. When working with roll media, proceed by inserting a media flange at

each end of the roll and then tighten the thumbscrews until the media roll is

firmly gripped between the flanges. Make sure the flanges are firmly

pressed against the roll. Place the flanges on the media support rollers at

the rear of the cutter.