SummaSign Pro T-series Cutters

User’ s Manual

General Information

1-27

Before lowering the pinch rollers, carefully check the position of the rollers in

relation to the drive sleeves. When the pinch rollers are DOWN, the two rollers

must run over the sleeves in order to ensure proper media traction. It is very

important that both media edges always rest on the sleeves in such a way that

the two pinch rollers, which are positioned 3 to 15 mm (0.1" to 0.6") from the

media edge, will run over the sleeves when lowered to the drive drum.

On the T1010 and T1400 units, two, three or more sleeves may be partly or fully

covered, depending on the media width used. To ensure precise and correct

positioning of the pinch rollers, special reference marks have been provided on

the head guide.

The central low-pressure roller on the T1010 Pro and T1400 Pro is used to

enhance media routing and keep the vinyl flat.

Ideally, this roller should be

positioned

halfway

between the two edge rollers and above one of the drive

sleeves.

For media widths smaller than 600 mm,

the central low-pressure roller on the

T1010 and T1400 units can be positioned in the UP position to disable it.

1.8.2. FEEDING AND POSITIONING MEDIA

The loading procedure described below has been found to give excellent

repeatability. When loading media, adhere to these step-by-step instructions

strictly.

è

To load media, proceed as follows:

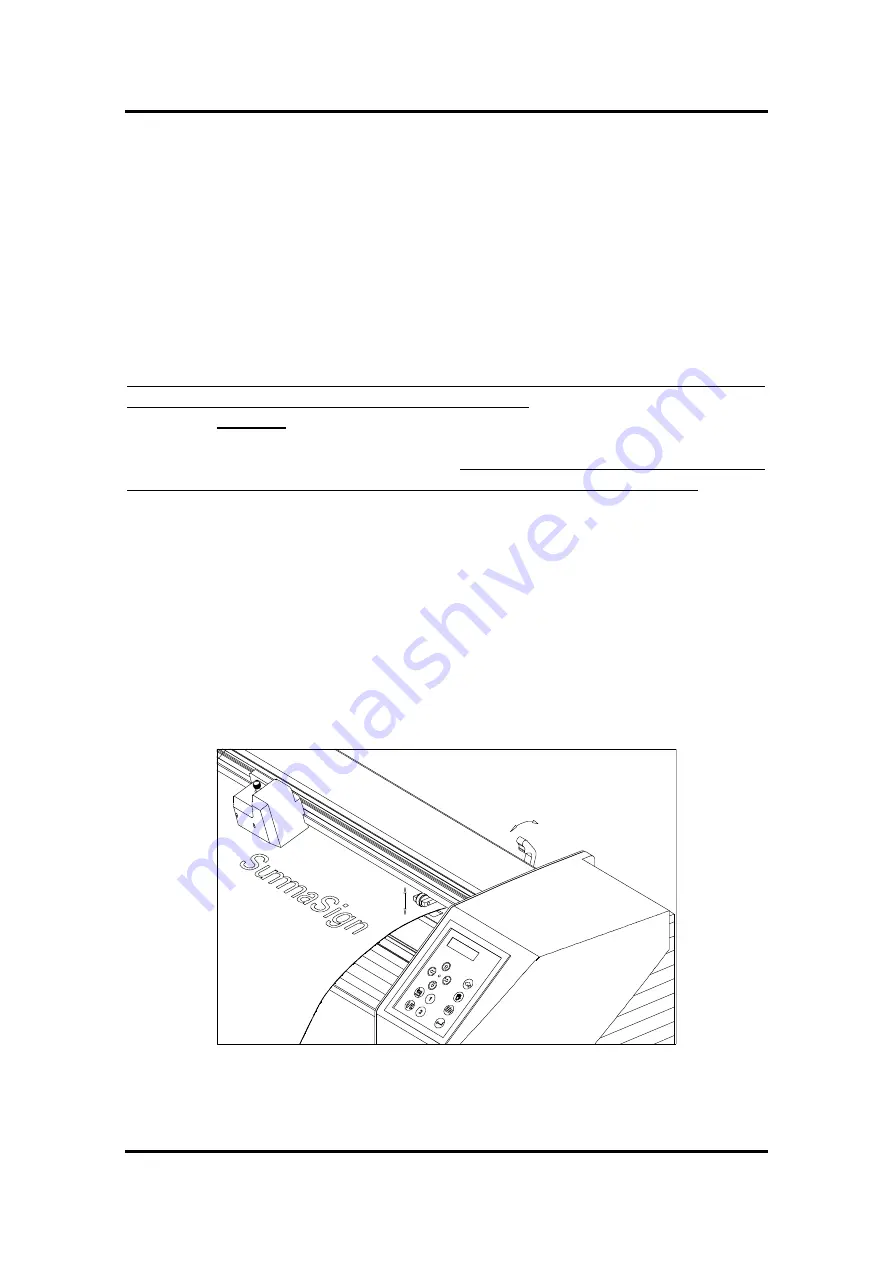

1. Raise the pinch rollers by means of the pinch roller lever arm located on

the right-hand side of the cutter, next to the control panel.

FIGURE 1-15 :

MEDIA POSITIONING

Summary of Contents for T1010 Pro

Page 1: ......