3-1

OPERATION SAFETY

1.

READ AND UNDERSTAND Operator’s Manual before using machine. Review at least an-

nually thereafter.

2.

VERIFY that all safety devices and shields are in place before using machine.

3.

KEEP hands, feet, hair and clothing away from moving parts.

4.

STOP engine, place all controls in neutral, set parking brake, remove ignition key and wait

for all moving parts to stop before servicing, adjusting, maintaining or unplugging.

5.

BE CAREFUL when working around high pressure hydraulic system.

6.

ALWAYS make sure that pressure is relieved from hydraulic circuits before servicing or dis-

connecting from tractor.

7.

DO NOT ALLOW RIDERS.

8.

USE EXTREME CARE when making adjustments.

9.

KEEP CHILDREN AWAY from machinery at all times.

10.

NEVER ALLOW anyone to walk or work under a raised piece of equipment without installing

cylinder and transport locks.

STEPS PRIOR TO OPERATION

1.

COMPLETE WARRANTY REGISTRATION CARD

A. Complete and return WARRANTY REGISTRATION CARD located at the beginning of

this manual.

RETURNING CARD ENTITLES YOU TO A FREE GIFT

.

B. Complete the OWNER REGISTER also located at the beginning of this manual (Serial

Number is located at the front of the hitch). OWNER REGISTER INFORMATION MAY BE

NEEDED WHEN ORDERING PARTS.

2.

VERIFY TRACTOR REQUIREMENTS

A. Recommended engine horsepower is 10-14 per foot.

NOTE: It may be necessary to reduce tillage depth, change tillage tools or perform multiple

passes if below this horsepower range.

3.

FINAL CHECK

A. After receiving or assembling your machine, it is a good practice to double check the

entire machine so all fasteners are securely tightened.

B. Make sure all grease fittings are in place and greased properly.

C. Inflate tires to recommended inflation pressure (see page 5-2) and check that wheel bolts

are tight.

SECTION 3 – OPERATION

Summary of Contents for CoulterChisel CC2815

Page 6: ...NOTES iv ...

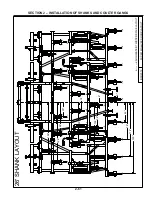

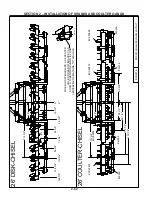

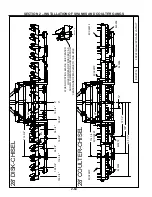

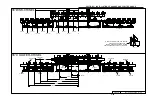

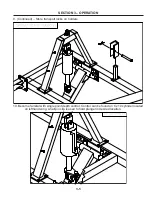

Page 65: ...2 53 SECTION 2 INSTALLATION OF SHANKS AND COULTER GANGS ...

Page 126: ...6 26 SECTION 6 PARTS ...

Page 128: ...6 28 SECTION 6 PARTS ...

Page 144: ...6 44 SECTION 6 PARTS NOTES ...