14

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

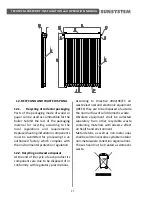

In areas with heavy snowfalls it is

recommended to further strengthen the

collector support fixation to the building

structure, as well as frequent inspection

to prevent any loosening of connections.

•

Collector protection against frost

.

To protect the collector against frost

(closed loop)

Propylene Glycol PG

heat-

carrier fluid is recommended.

Table 5

Relation between Propylene Glycol and wa-

ter

PG

/ Propylene

Glycol /:

Water

Freezing point

20% : 80%

-

7

℃

30% : 70%

-

13

℃

40% : 60%

-

23

℃

50% : 50%

-

34

℃

If you choose water as heat carrier, it is

recommended to connect to the system

a controller unit supporting antifreeze

function working with water as heat-

carrier.

•

Collector protection against

overheating

.

If the system is designed to

power a central heating circuit it would

produce more hot water than necessary

in the summer period. In this case, we

recommend that the system be fitted with

a device for heat dissipation or to add

more users to the hot water circuit in the

summer (swimming pool or other similar

consumers).

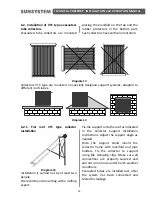

7.2.

Collector outlets/connections

Upon design of vertical risers it is

recommended that the heat carrier flow

speed

be between 0.5 and 0,8 m/s, and the riser

pipes be made of copper.

For example: for 20 m

2

of collector area

the required flow rate is 1000 l/h at a heat

carrier speed of 0,5 m/s - recommended

pipe section is ø28x1 Cu.

We recommend - two and/or more

collector fields to be connected using the

Tichelmann principle.

When installing the collector it is

mandatory that on its highest point

an automatic air purge be installed to

facilitate system charging.

Connection of collectors is carried out

using Hollander joints.

Diagram 24

For PK New Line model using adapter

nipples for copper pipe ø22.

For PK Classic model using Hollander

joints at 1/2“

The use of galvanized pipes and fittings

for connecting collectors to water tanks

is forbidden due to electrical corrosion

hazard.