15

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

Fixing the fittings

:

- Always use two opposing spanners when

tightening the compression fittings. Do

not twist the

copper pipe (inlet/outlet)

as the header maybe damaged.

- Tighten with standard length spanners

using moderate torque force. Do not

overtighten the fittings.

- Flood the circuit with water and check

the for leaks at the compression

fittings. If leaking then

loosen the

fitting completely, and wrap the Teflon

plumbing tapes or a suitable sealing

compound.

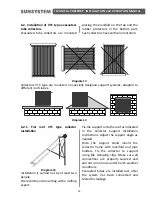

- For several collectors connections, it

is necessary to use the flexible pipes

between two collectors because of the

Expansion on heating and contraction

on cooling.

- Heat loss from the piping can be

significant and should be taken to

insulate any possible points

of heat loss.

Ensure the insulation material is tight

against the pipeline, inlet and outlet.

Using the silicone sealant to form a

water-tight seal on the temperature

sensor.

The insulation foam should be

protected against the UV. The circulation

pump should be also

insulated otherwise

it could be a source of heat loss.

7.3.

Stagnation temperature

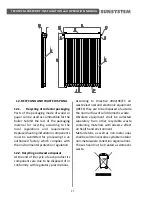

Stagnation refers to the condition that

occurs when the pump stops running,

due to pump failure, power blackout, or

as a result of a high tank temperature

protection feature built into the

controller, which turns the pump off.

If a PTRV is installed on collector inlet

or outlet the collector will continue to

increase in temperature until the limit of

the temperaure relief valve is reached,

at which point hot water will be dumped

from the system. If a PTRV is not installed

on the collector, steam will form in the

header. Eventually some steam may feed

back to the storage tank via the return

line.

The PTRV on the tank will open to release

pressure or heat as required. Under such

conditions the manifold will normally

reach a maximum temperature of around

160°C/320°F. Generally the heat returning

from the collector in the form of steam is

not enough to affect a continued increase

in tank temperature (ie. Heat input <tank

heat losses)Under normal use stagnation

should rarely occur as a result of pump

stoppage, since power blackouts normally

happen during storms and not clear

sunny weather. High tank temperature

protection should only occur when hot

water is notused for several days (when

on holiday), and only during strong

periods of sunlight (summer). If leaving

the house for an extended period of time

(more than 2 - 3 days), it is advisable to

cover the collector panel or design the

system with a heat dissipation device

or alternative use for the heat, thus

preventing overheating of the system

and collector stagnation. Stagnation of

the solar collector will NOT damage the

solar collector, however insulation used

on the piping close to the manifold inlet

and outlet should be able to withstand

temperatures of up to 200°C/395°F.

(Eg. Glass wool or mineral wool-with

an exterior wrap of aluminium foil, thus

protecting against the elements).

7.4.

Mounting of Temperature sensor of

VTC type collector

The solar collector temperature sensor