16

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

should be coated with a thick layer of

thermal paste and inserted into the

sensor sleeve to the full depth. If the fit is

too loose, slide a piece of copper plate or

wire in beside the sensor, Seal the sensor

sleeve opening with silicone sealant

to prevent water ingress. Ensure that

sensors used on the collector are high

temperature rated (up to 250°C/486°F), in

particular the cable.

7.5. Mounting of Safety temperature

valve

It is recommended, and may be required

by regulations, that a temperature control

device (safety tempetarure value) be

fitted into the hot water pipe between

the water heater and bathrooms and

en-suites to reduce the risk of scalding.

This is achieved by controlling the water

temperature to below 50°C/122°F

(temperature may be adjustable).

7.6. Pressure control. Temperature

control. Relief valve.

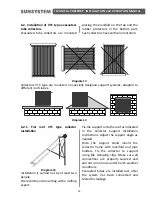

Regardless

of

the

installation

configuration, pressure release values,

expansion vessels and/or other pressure

control devices must be installed. The

solar loop should be designed to operate

at no more than 800kPa -

PRV may be

850kPa. (800kPa = 8bar = 116psi)

For installation where mains

pressure

water is used, the system should ideally

be designed to operate at a pressure of

<500 kPa,

achieved by use of a pressure

limiting/reduction value.

For the reliable operation of system, we

recommend you check the lever of the

pressure and temperature return valve

(PTRV) every six months. The PTRV lever

should be raised and dropped gently

without effort.

Collector working (operating) pressure

should be secured using a pressure relief

valve at 6 bars.

An expansion vessel must be mounted in

order to take up the extra volume of fluid

caused by heat expansion. Recommended

capacity of expansion vessel is 4 ÷ 5 L/m

2

of PK type collector area, and 8 ÷ 10 L/m

2

of VTC type collector area.

To avoid damage to system and heat

carrier circuit, all air purge valves must

be closed upon purging of air from the

system. This will prevents the release of

steam and the penetration of oxygen

from the ambient air.

7.7. Filling of system.

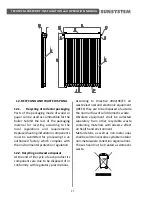

To prevent overheating, the filling

of system must be carried out in the

morning or evening in the absence of

direct sunlight.

Direct use of collector for hot water

preparation is not allowed because of the

eventual clogging of pipes over a short

time by limescale deposits.

Inside collector pipes and risers circulates

a certain fluid (water, propylene glycol or

Tyfocor of freezing point corresponding

to the requirements of certain installation

(see section 7.1 of this manual.)When

using any other heat carrier fluid to fill the

collector manufacturer does not take any

responsibility for product warranty.