21

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

8. COMMISSIONING

Must be performed by an

authorized service technician/

service shop for such operations.

Before commissioning of solar collector

into operation, check:

- The air-tightness of all connections

- System air purging

- Insulation of pipelines: must be UV

resistant and temperature shock proof

as well as bird- and rodent-proof in

structure.

- Electrical connections: controller, pump

9. DAMAGE PREVENTION AND SERVICE

MAINTENANCE OF COLLECTORS

Any changes in design or con-

struction of solar collectors are

strictly prohibited. Detection of

such makes warranty null and

void. As changes in design and

construction shall be considered

the removal of any manufacturer-

embedded items, incorporation

of additional components in the

collector, replacement of any com-

ponents with similar or analogues

not explicitly approved by the

manufacturer.

9.1.

It is recommended that yearly

maintenance be carried out by

an authorized service. All service

maintenance must be logged on the

warranty card.

- Checkup of operating pressure, pump

operation, hydraulic connections.

- Checkup of heat carrier fluid,

replacement thereof.

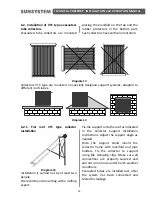

9.2. Cleaning of collectors from dust

deposits, fallen dry leaves and twigs

Keeping the collector surface (type PK

or VTC) clean is a prerequisite for good

performance. A dusty collector (due to

lack of rainfall, dusty ambience) can be

cleaned up in early morning hours before

it is heated by sunlight using:

- Warm water, soap/glass cleaner solution

and a soft cloth when the collector is

mounted in an easily accessible and safe

place;

- Pressurized water jet when the collector

is mounted in a hardly accessible place.

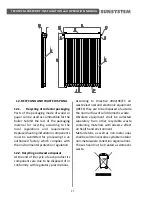

9.3. Replacing a broken tube on VTC type

heat pipe collector

In any event of broken collector tube

it needs to be replaced as quickly as

possible. Despite the damaged tube, the

collector can still operate, but its efficiency

will drop. Clean broken glass to prevent

future injuries. We recommend that

replacement of the broken collector tube

be carried out by an authorized installer /

service observing all safety norms.

10. WARRANTY TERMS

Failure to observe the installation

and operating requirements de

-

scribed in the manual and the ser-

vice booklet voids the warranty.

10.1. Manufacturing defects and

materials guarantee

NES Ltd. expressly guarantees that