3

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

TECHNICAL PASSPORT. INSTALLATION and OPERATION MANUAL

1. EXPLANATION OF SYMBOLS AND

SAFETY INSTRUCTIONS

1.1. Explanation of symbols

CAUTION!

-

Important

recommendation or warning

concerning safety conditions during

installation and operation of the solar

collector.

DANGER!

-

fault or improper use

may cause injury or be hazardous to

life

of humans or animals.

INFORMATION

-

Important

information on the proper operation

of the product.

1.2. Requirements to solar collector

installation place

This

manual

contains

important

information for the safe and correct

installation, start-up and trouble-free

operation and maintenance of the

solar

collector.

The solar collector can be used to produce

domestic hot water and support of space

heating system only in the manner

described in this manual.

The application and any other was the

area of operation is not recommended by

the manufacturer and is not responsible

for the occurrence of defects or failures.

Note the

collector

type data on the

factory rating label and the technical data

provided in chapter 1

2 in order to ensure

proper operation of the product.

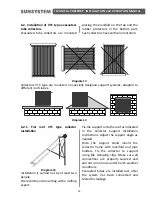

1.2.1. Instructions to collector installer

During installation and operation, the

country-specific

requirements

and

regulations must be observed:

•

local construction regulations on

installation

on building – mass of the

system to comply with the building

structure.

•

regulations and norms concerning

safety installation and operation of solar

collectors - protective gloves, eyewear

should be used; make sure collector is

securely attached to the building.

Use only original

SUNSYSTEM parts

DANGER of structure damage /

injury from fall.

The weight of collector/collectors

must comply with the building

structure, namely the distribution

of weight; strong and secure

fixation of collector support to

the roof/façade of building. We

recommend the securing of the

area during installation and the

construction of roof barriers

protecting against downslide of

snow mass. Failure to comply with

these recommendations can lead to

fatal consequences.

Risk of injury, burn upon

installation and maintenance of

solar collectors:

- On contact with broken glass/

vacuum tube

- On contact with collector in

function because of its high

temperature.

We recommend the use of

protective equipment, gloves,

eyewear (goggles), clothing.

Installation and maintenance of

collectors must be carried out in

the early morning hours. When the

collector is still cold you can cover it

with tarpaulin to avoid its heating

by direct sunlight.