5

The strength of the welded steel frame, combined with the considerable durability of the stainless steel

hopper, allows to obtain a very high overall quality level in the category to which the distributors of carried

SALT spreader.

The SALT spreader P-PRO model has a distributor completely in stainless steel equipped with a spreader

disc with four adjustable vanes in four different positions, in order to obtain the maximum spreading

precision and uniformity in the distribution.

The feeding of the disc is by gravity through two opening, located on the side of the hopper, inside

of which a mix/agitator is applied, in order to prevent the SALT lumps formation. The side discharge ensures

greater uniformity of spreading as the SALT falling on disk is immediately hit by the vanes without

dispersions and making sure that each pallet receive the same amount of SALT.

A sheet case is placed in front of the disc, in order to prevent the spreading in the front side of the machine.

The dosage of the product takes place by varying the section of the hopper openings by means of a split

lever system so as to allow even spreading to the right or left with respect to the direction of progress.

The SALT spreader is connected through a gear box (1:1) with gears module 17 in order to be resistant,

absorbing possible power stress.

2.5

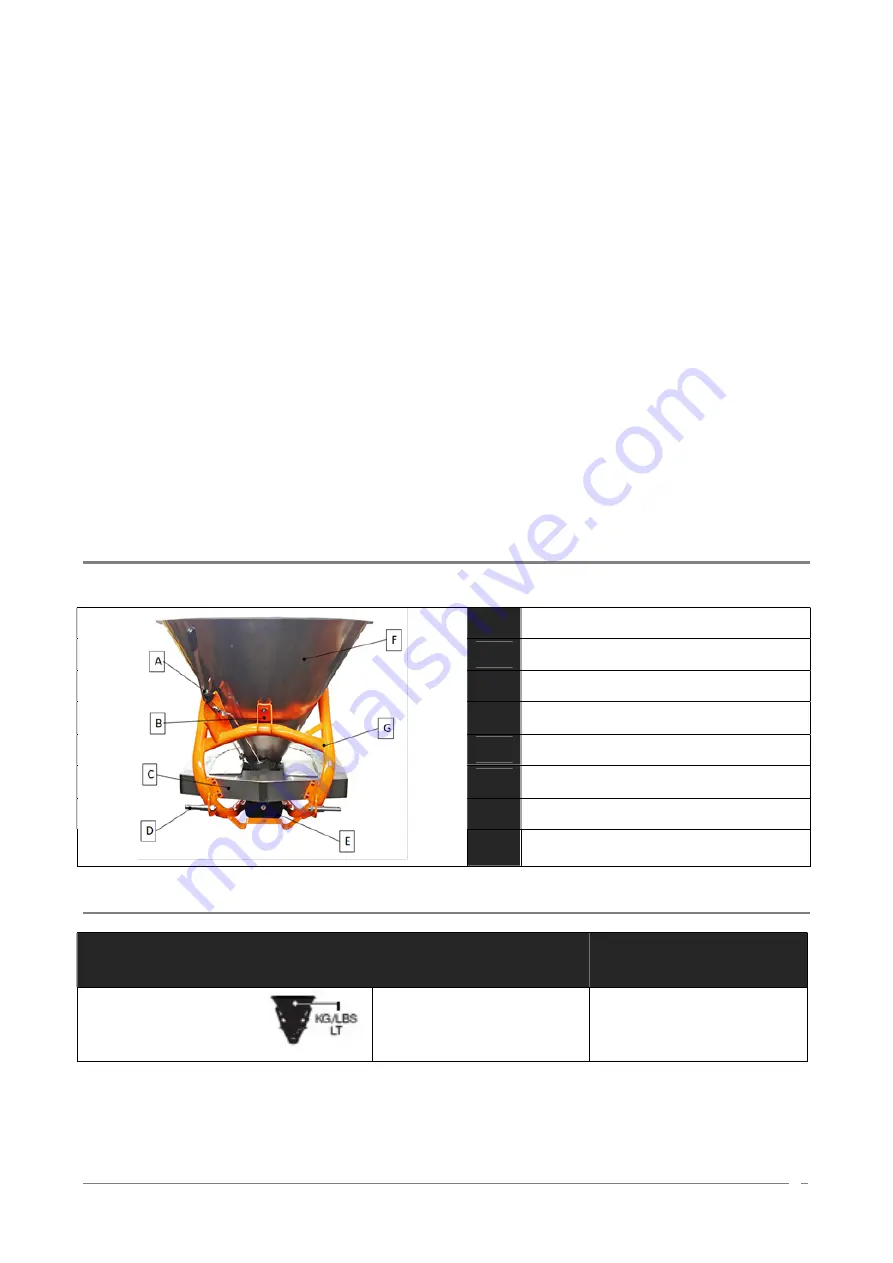

IDENTIFICATION OF COMPONENTS

A

Adjusting lever

B

Third hitch point

C

Rear shield

D

Hitch pin

E

PTO shaft hitch

F

Hopper

G

Steel frame

H

Vanes

2.6

TECHNICAL DETAIL

Mod.

P-PRO

180

P-PRO

300

CAPACITY

200/441/170

320/705/270