wiring should be bare or tinned copper, two conductor,

stranded, PVC insulated, with a PVC UV rated jacket

suitable for exterior use. In locations that often experi-

ence electrical storms and electrical atmospheric activi-

ty the low voltage sensor wire should also be shielded

with the shielding grounded.

Low voltage wire shall be rated for the full ranges of

temperatures expected in the location, typically wire is

rated up to 160

°

F. The low voltage sensor wire must

not be in direct contact with the pipes as the wire insu-

lation may melt when in contact with a hot pipe. Low

voltage sensor wire must be run OUTSIDE the pipe in-

sulation. Where the low voltage wire is run in an ex-

posed location, it should be run OUTSIDE the pipe insu-

lation but UNDER the insulation jacket or wrap to pro-

tect the wire from UV exposure.

4.7 Installing the Solar tank

The solar tank is heated indirectly through the external

heat exchanger by separate pumps on the collector

loop and the potable side of the heat exchanger.

When plumbing the SunEarth solar storage tank and

drainback reservoir make sure that all the components

are accessible and easy to reach. Ensure that there is

clear access to the storage tank, circulating pump,

drainback reservoir, mixing valve, flow meter and other

key components. If a component in the potable water

side of the system may require future service or

maintenance make the connections with brass unions.

Use only brass nipples and unions and copper and

brass fittings in plumbing the solar storage tank and

drainback reservoir. The use of galvanized fittings or

nipples, CPVC or PVC piping is prohibited.

Check valves are NOT ALLOWED anywhere in the col-

lector loop. A check valve in the collector loop will pre-

vent proper draining of the collectors and may result in

freeze damage. If the pump used has an integral

check valve, the check valve must be removed before

installing the pump in the system.

Hard copper connections to the city cold water supply

line and the home hot water feed lines are recom-

mended. The gaskets in standard water heater flex

hose connectors can become brittle and compressed

over time and begin leaking on the water heater. If

not detected in a timely manner even a small drip or

leak may cause serious damage to the tank’s electrical

components or, in extreme cases, may cause the tank

to leak from the outside in.

Tank plumbing is required to provide for the isolation of

the solar storage tank from the city cold water supply

line by means of an isolating ball valve.

The differential temperature controller shall have a

screen readout to show temperatures of the collector

and storage tank. Otherwise, line thermometers shall

be installed in the collector supply and return lines to

allow for a simple diagnostic check of proper system

operation. On a sunny day the hot water return line

should be approximately 5 – 15°F warmer than the wa-

ter in the collector supply line.

The specified SunEarth controller continuously displays

the temperature of the SunEarth collectors (T1) and

the temperature at the bottom of the solar tank (T2).

In addition, you may choose to install a third tempera-

ture sensor (T3); this is normally installed at the hot

water outlet on both single and double tank systems.

The Torrent Drainback system typically requires a high

head, low flow circulating pump. The maximum head

on the pump curve must be greater than the static lift

head required to fill the system. The static lift head is

the vertical height from the bottom of the drainback

tank to the highest point in the system (usually the col-

lector outlet header). When the pump is filling the sys-

tem it will be pumping against the static lift head and

should provide no less than 0.5 GPM flow. Once the

system has been filled to the top of the collector, water

will start to cascade down the return line filling the re-

turn line as far as the drainback reservoir. Once this

pipe is fully flooded the return line will start to siphon,

resulting in an increase in flow as the system transi-

tions from the filling condition to the running condition.

In the running condition the flow rate should not ex-

ceed 5 GPM. Good pump selection requires that the

pump provide enough lift for the filling condition with-

out excessive flow in the running condition. This is

usually achieved using a pump with a “steep” pump

curve. For multistory buildings, this can be especially

challenging unless the drainback tank is located on the

upper floor.

When there is a risk of pump cavitation due to high

flow rates, a pump throttling valve (COMPONENT #22)

may be located on the discharge, or upstream, side of

the pump to adjust the solar loop flow rate and to pre-

vent cavitation of the circulating pump. Cavitation is a

fluid condition that can lead to pitting or other damage

to the pump impeller. A throttling valve on the return

piping from the collector to the drainback tank can also

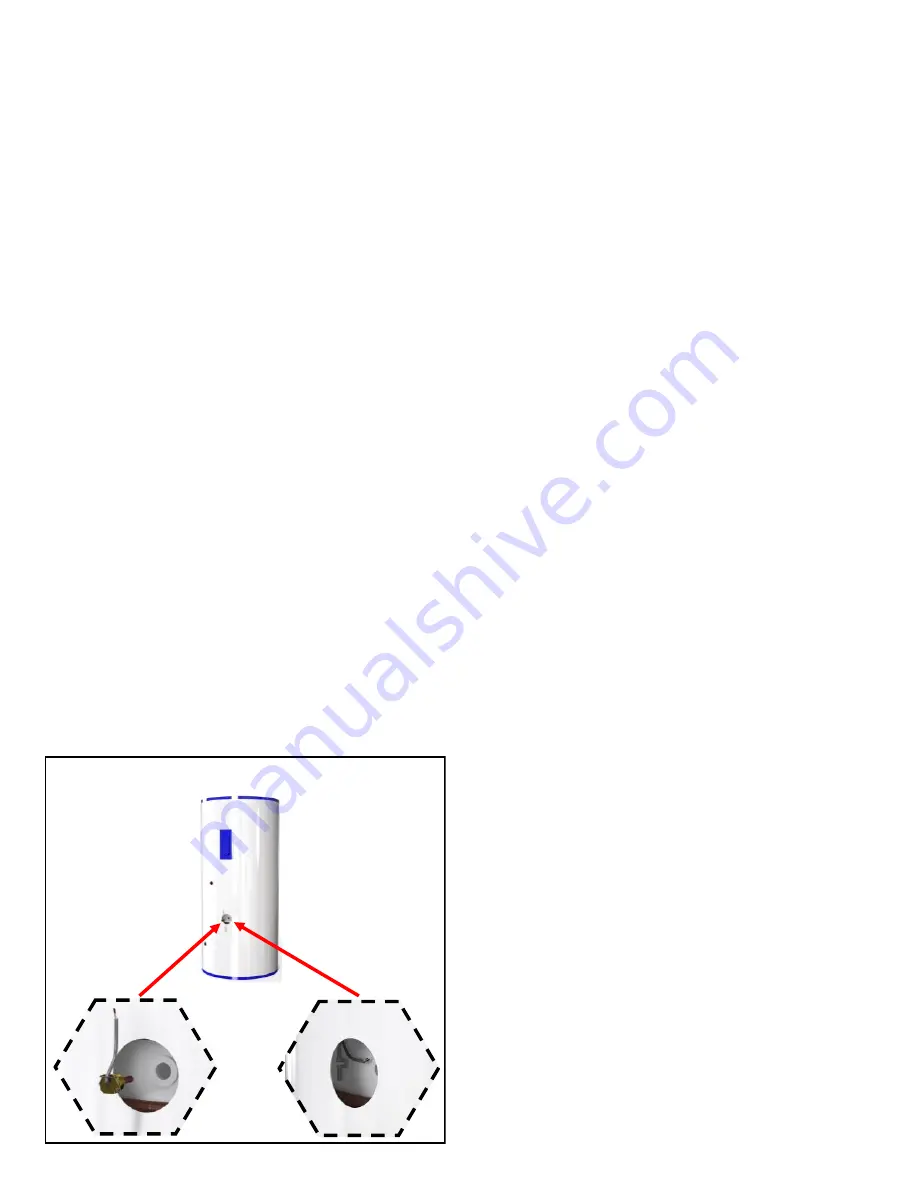

TANK SENSOR

Fig.13

THERMOWELL

JIFFY CLIP (ALTERNATIVE)

Summary of Contents for CASCADE 2

Page 29: ...APPENDIX F ...

Page 30: ...APPENDIX F ...