P.10

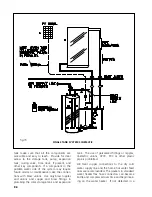

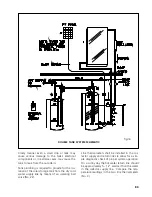

In a single tank system install a third thermome-

ter (No. 3) directly after the mixing valve above the

solar storage tank. In a two tank system you may

install the third thermometer either directly above

the hot outlet on the solar storage tank or after

the mixing valve on the back-up water heater.

Two way ball valves must be installed on either

side of the circulating pump (Nos. 12 and 14) so

that the pump can be isolated from the collector

loop. Repairs or routine system maintenance can

be completed without introducing air into the

system or draining the HTF (Nos.12 and 14).

The expansion tank shall have a minimum 150

PSIG working pressure and have a total volume

of not less than 4.4 gallons. The standard facto-

ry charge should be 40 PSIG. The expansion tank

shall be Rheem/Ruud Therm-X-Guard Model RRT-

12 or equal (No. 8).

A high quality thermostatic mixing valve is a

required component in all OG-300 certified sys-

tems and should be plumbed in line with brass

union connections for ease of future repair or

replacment (No. 31). The specified mixing valve

shall be the Heatguard model HGBASE or equal

and shall have an operating range between 95°F

and 140°F. The mixing valve shall be set to 120°F.

The 3/4" cold water supply line to the solar stor-

age tank must be insulated with minimum 7/8"

X 1/2" pipe insulation to a minimum distance of

5' behind the storage tank, or to the wall if clos-

er than 5'.

The temperatures generated by your SolaRay sys-

tem will vary throughout the year. In the

Northern Hemisphere the water temperature will

be hottest in the spring and summer months

while cooler temperatures are to be expect from

November through March. On sunny days sys-

tem temperatures may range between 110ºF to

180ºF depending upon the season and hot water

demand. The mixing valve described above

blends the hot and cold water supplies to deliver

hot water to your fixtures at a safe, controlled

temperature.

WARNING: SCALDING CAN OCCUR WITHIN

FIVE SECONDS WHEN WATER TEMPERA-

TURES APPROACH 140ºF. THE MIXING VALVE

SHOULD BE ADJUSTED BY YOUR CONTRAC-

TOR TO PROVIDE WATER TO YOUR FIXTURES

AT NO MORE THAN 120ºF.

4.9 Tank Insulation

SunEarth requires that the solar storage tank

must have a minimum insulation value of R-20.

Most solar storage tanks now come with R-16.7

factory insulation. Conventional back-up elec-

tric water heaters have insulation values between

R-12 and R-20. The R value expresses the ther-

mal conductivity of the insulation material. The

higher the "R"value the more effective the insu-

lation material is at preventing heat loss.

Whereas solar storage tanks do not come with

sufficient factory insulation to meet SunEarth’s

insulation specification, a supplemental insula-

tion jacket also must be installed. We recom-

mend an aluminum foil "bubble-pack" insulation

material such as manufactured by Reflectix (or

equal). When properly applied, the insulation

jacket will increase the overall level of the solar

tank insulation to approximately R-22. In two

tank retrofit installations an installation jacket

also must be installed on the back-up water

heater.

If your Solaray system is installed in a new home,

SunEarth specifies that the conventional water

heater in a two tank system have an insulation

value of R-20 (Rheem 82VR52-2, Ruud EVR5202

or equal). Tanks with R-20 insulation or higher

do not require a supplemental insulation jacket.

For best results, cut three 1" strips of material

and affix these to the top, middle and bottom of

your water heater or storage tank with the man-

ufacturer’s tape. This space creates an air gap

between the heater and the insulation and pre-

vents heat conduction. Wrap the material around

the water heater or storage tank and secure the

seams with the manufacturer’s tape.

Thoroughly insulate the top of the water heater.

Fit the insulation snuggly around the brass nip-

ples or unions and temperature and pressure

relief valve on the top of the water heater. If you

have an electric water heater, cut two windows

in the insulation around the access plates cover-

ing the upper and lower thermostats and heating

elements. Insulate the area over the assess

plates, but make sure that these areas always

remain accessible for service or repair as neces-

sary.

The storage tank should not be placed directly on

an uninsulated floor or concrete slab. The tank