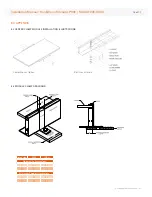

5.3 OPTION B: RACKING MANUFACTURER INTEGRATED GROUNDING METHODS

SunEdison modules can be grounded by bonding PV modules to a grounded racking system. Integrated grounding methods

must be appropriately certified to UL standards and must be in accordance with the specified instructions of the respective

manufacturer. SunEdison recommends using the BURNDY WEEBs integrated rack grounding, part numbers WEEB-ADC and

WEEB-ADR. These devices use 304 stainless steel and electrically grounds the module to the supporting structure and contain

specialized teeth to penetrate anodized aluminum for a proper electrical connection to the supporting structure. Should you choose

a rack integrated method that is not approved by UL please contact SunEdison before proceeding to determine compatibility.

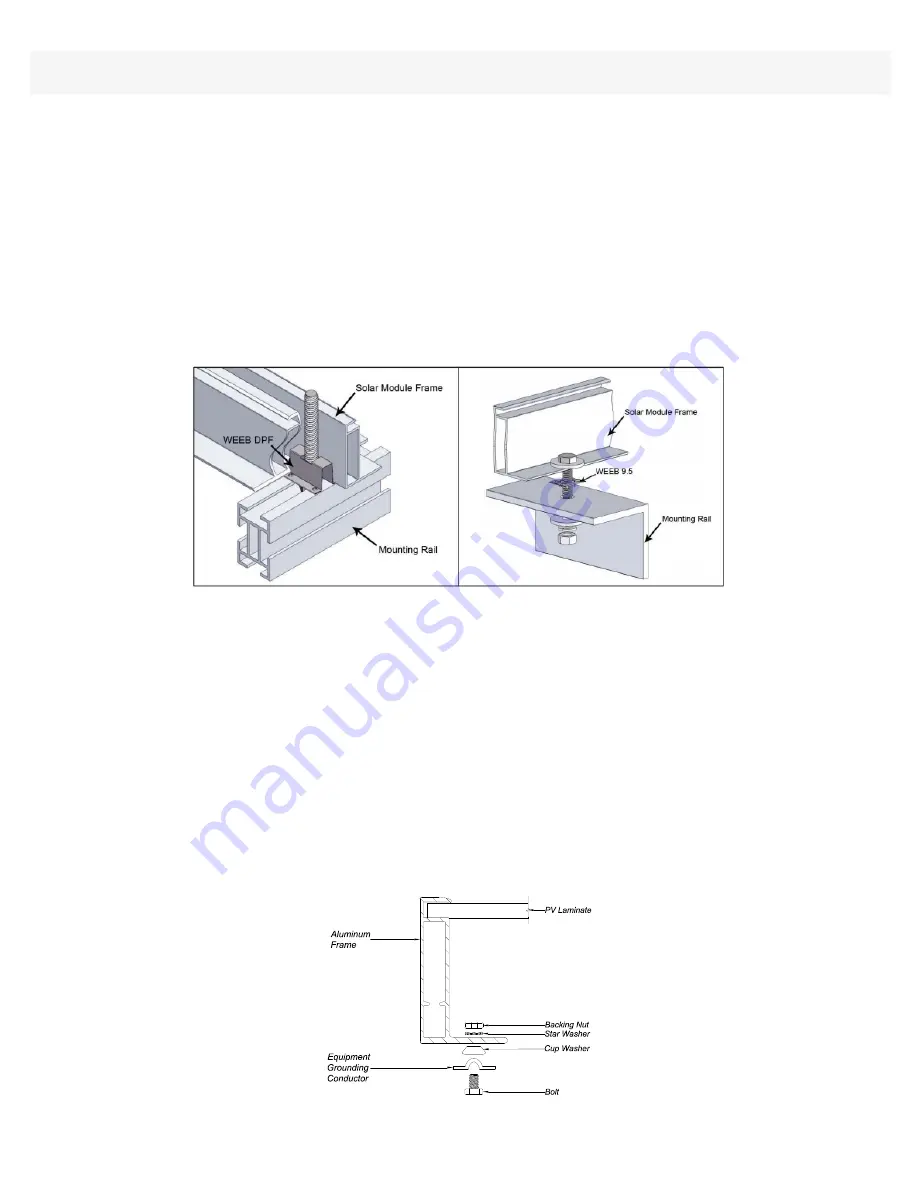

5.3 OPTION C: BOLT WIRE ASSEMBLY

1. A grounding bolt assembly, of at least minimum reccommended size (see Option A) must be attached at one of the designated

aforementioned grounding hole locations. Using only stainless steel hardware, insert a stainless steel bolt first through the

stainless steel cup washer, and then through the grounding hole.

2. Loosely add a stainless steel backing nut and a toothed lock washer to the bolt.

3. Bend the EGC into an Omega (

Ω

) shape to tightly fit between the partially installed bolt head and cup washer. The EGC shall be

exclusively in contact with the steel.

4. Tighten the bolt to approximately 35 in·lbf (4 N·m) of torque. The toothed washer must penetrate the coated aluminum.

5. Route the correctly sized EGC wire in such a way to avoid contact with the module's frame.

11 of 17

Figure 4: Grounding Lug Assembly

Figure 5: Bolt Wire Assembly

Installation Manual: SunEdison Silvantis P300 | M330/F330/D330

© Copyright 2014 SunEdison, Inc.