12 of 17

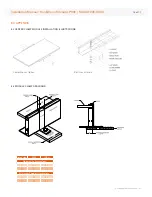

5.3 OPTION D: ALTERNATIVE GROUNDING

• All other code compliant frame grounding methods that are certified to UL contact SunEdison for approval.

5.4 ELECTRICAL INSTALLATION WARNINGS

• Installation and maintenance should be performed by qualified personnel only.

• Use insulated tools during installation, troubleshooting and maintenance of photovoltaic modules.

• Installers should adhere to all applicable local, regional, and national codes and regulations when designing and

constructing the photovoltaic system.

• Photovoltaic modules produce DC electrical energy from light. When illuminated, each module can have a DC potential

of greater than 45V and should be handled with care.

• Disconnecting modules under illumination may cause electrical arcing which may result in burns, fires, or other

problems. Modules connected in series should not be disconnected under illumination.

• Always use a wire management system that keeps wires and cables out of direct contact with edge surfaces which

could cut or damage the insulation. Do not allow wires to rest on the ground or roof surface.

• The module junction box should not be opened or modified in any way in the field.

• Do not use mirrors, lenses, or other techniques to magnify or concentrate additional light on the module.

6.0 DISCLAIMER OF LIABILITY

The information in this manual is based on SunEdison’s knowledge and experience and is believed to be accurate. However, all

information in this manual (without exception) including recommendations and specifications does not constitute a warranty,

expressed or implied. SunEdison reserves the right to change the manual, the module, or specifications without prior notice.

The product warranty shall be VOID if handling and installation of the product does not conform to SunEdison’s written

installation instructions, or if the product has been reworked, repaired or otherwise modified in a manner not previously

authorized by SunEdison in writing, or if the product is installed in an environment for which it was not designed. SunEdison

shall not be liable for special, indirect, consequential, contingent or incidental damages related to or arising from the

installation or use of the product by purchaser under any circumstances.

SunEdison assumes no responsibility for any product application or use which is beyond SunEdison’s direct control.

SunEdison does not accept responsibility and expressly disclaims liability for loss, damage, or expense arising out of or in any

way connected to such installation, operation or maintenance of the product.

International Product Certifications:

IEC 61215, IEC 61730, CE, UL 1730, and Safety Class II certifications ensure that SunEdison solar products operate safely and

comply with global electrical, performance, reliability, and fire safety codes.

Certification

• IEC 61215 certified by TÜV SÜD

• IEC 61730 certified by TÜV SÜD to ensure electrical safety

• Stringent outgoing quality acceptance criteria benchmarked to industry standards

• UL1703 listed by CSA for US and Canada

Environmental

AB8 (-50°C to +40°C)

Fire Resistance Rating

Class C

SunEdison Modules are certified by:

Installation Manual: SunEdison Silvantis P300 | M330/F330/D330

© Copyright 2014 SunEdison, Inc.