1.0 INTRODUCTION

The purpose of this guide is to provide general information regarding the proper installation and handling of SunEdison

photovoltaic modules that serve residential, commercial, and industrial segments. System design, construction, and

commissioning should be performed by qualified personnel only.

To ensure system integrity, designers, installers and operators must meet all mechanical and electrical requirements for

the system and its components. It is the responsibility of the system designer and installer to ensure that all codes and

requirements are followed as well.

Please review all the sections that pertain to proper installation of modules listed in this guide. The instructions detailed in

this guide must be followed throughout the module’s lifetime deployment. If you need additional information about the safe,

proper use and handling of SunEdison photovoltaic module products, please contact SunEdison.

2.0 PHOTOVOLTAIC MODULES PRODUCT CODE

3.0 MODULE OVERVIEW

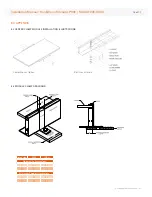

SunEdison Silvantis Photovoltaic modules consist of a series of electrically interconnected crystalline silicon solar cells that are

sealed within a laminated sheet of tempered glass superstrate* and EVA/back-sheet substrate. These laminates are secured

inside an aluminum frame to provide rigidity and a means for attachment to mounting sub-structures. The frames should not

be modified or removed.

* Tempered glass may have AR coating.

• Photovoltaic modules are designed and constructed for outdoor use. Do not submerge modules in water at any time.

• The front and back of each module is labeled with a product bar code. Do not cover, remove or deface these labels.

This may be required for product identification.

• Damage to the glass surface or the anti-reflective coating can impact the power output and overall efficiency of the

system. Scratches, handling marks, or any damage to the glass surface must be avoided.

• For best performance and to avoid potential issues, keep the front side of the module clean and free of obstructions

including covers, tape, adhesives, paint and debris.

3.1 MAINTENANCE

Check modules, glass, and frames for damage. Regularly inspect all SunEdison solar modules for safe electrical connections,

sound mechanical connections, and freedom from shading and corrosion. If dirt or debris buildup becomes excessive,

periodically clean the glass only with a soft cloth using mild, non-abrasive detergent and water. When using mild cleaning

liquids, a neutral pH in the range of 6.0 to 8.0 is recommended. Chemicals with pH less than 6.0 or greater than 8.0 should

be avoided as it may damage the glass surface and or the AR coating. Please consult with system designer to decide the

cleaning and inspection frequency according to local environmental conditions.

Do not power wash or use harsh cleaning materials or objects such as scouring powder, steel wool, scrapers, blades, or other

sharp instruments to clean the glass surface of the module. Use of such materials will invalidate the product warranty.

WARNING: Use caution when cleaning the back surface of the module to avoid penetrating the substrate materials.

2 of 17

P280ByC

P285ByC

P290ByC

P295ByC

P300ByC

P305ByC

M310ByC

M315ByC

M320ByC

M325ByC

M3330ByC

M335ByC

F310ByC

F315ByC

F320ByC

F325ByC

F330ByC

F335ByC

D310ByC

D315ByC

D320ByC

D325ByC

D330ByC

D335ByC

Installation Manual: SunEdison Silvantis P300 | M330/F330/D330

© Copyright 2014 SunEdison, Inc.

Silvantis

TM

P300

Multicrystalline Modules

Silvantis

TM

M330

Monocrystalline Modules

Silvantis

TM

F330

Monocrystalline Modules

Silvantis

TM

D330

Monocrystalline Modules