7752C Rev. D

3

rev. 01/23/15

SETUP

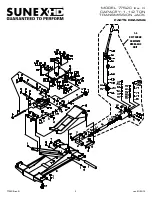

PLEASE REFER TO THE EXPLODED VIEW DRAWING IN THIS MANUAL IN ORDER TO IDENTIFY PARTS.

1.

Refer to the exploded view drawing on page 5 to identify jack components.

2.

The #3-7 and 3-13 brackets must be installed on the #3-8 saddle plate with the #3-6 bolts, #3-9 washers and #3-10 wing nuts as shown in

the exploded view drawing.

3.

The #3-4 chains must be attached to the #3-7 brackets as shown in the exploded view drawing and secured to the brackets with

the #3-1 bolts, #3-2 washers, #3-3 lock washers and #3-5 nuts provided.

4.

Assemble the #3-16 chain hooks to the #3-15 adaptor bolts with the #3-14 wing nuts as shown in the drawing.

5.

Secure the #3-15 adaptor bolts to the two remaining #3-13 brackets using the #3-12 washers and #3-11 nuts.

6.

Air may get trapped in the hydraulic system during freight and handling.

PURGING AIR FROM THE HYDRAULIC SYSTEM:

a. Rotate the release knob at the top of the hydraulic block in a clockwise direction until tight.

Now turn it in a counterclockwise direction two full turns.

b. Activate the hand pump #1-45 about 15 times.

c. Rotate the release knob at the top of the hydraulic block in a clockwise direction until tight.

d. Activate the hand pump until the lift arm is raised to maximum height. You should experience a full pump stroke with each

incremental pump.

e. Repeat steps "a" through "d" until all air is purged from the system.

OPERATING INSTRUCTIONS

This is the safety alert symbol used for the OPERATING INSTRUCTIONS section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

1. Lift the vehicle to the desired work height, and support the vehicle in accordance with the lift manufacturer's recommended

lifting and support procedure

s.

2. Position the transmission jack directly under the transmission. Turn the release valve knob all the way in a clockwise direction until

it stops. Pump the handle, and the saddle assembly will start to rise. Raise the saddle to a height very close to the center of

balance point of the transmission, but do not touch the transmission.

3. Loosen the four bolts that secure the four brackets to the saddle. The brackets can be adjusted in and out to help position the

transmission on the saddle. Now gently raise the saddle so it supports the transmission. Adjust the four brackets in position

against the transmission, and tighten the wing nuts that secure the brackets to the saddle. Fore and aft saddle tilt adjustments are

sometimes necessary to properly position the transmission on the saddle. Side to side tilt positioning may be necessary for the

same reason and can be accomplished by activating the side to side tilt knob.

4. The chains should be pulled over the center of balance portion of the transmission and secured on the chain hooks. Rotate the

#3-10 wing nuts to take up the slack in the chain and secure the transmission to the saddle.

5. Remove the transmission from the engine according to instructions in the vehicle service manual.

6. Once the transmission has been disconnected from the engine, very slowly turn the jack's release knob in a counterclockwise

direction to make sure the jack's saddle and transmission do not hang up on any undertruck components, wiring, fuel lines, etc.

Continue to lower the jack all the way down.

7. Remember to secure the transmission to the saddle before installing, and follow the vehicle manufacturer's installation instructions.

PREVENTATIVE MAINTENANCE

This is the safety alert symbol used for the PREVENTATIVE MAINTENANCE section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death.

1.

Always store the jack in a well protected area where it will not be exposed to inclement weather, corrosive vapors, abrasive dust, or any

other harmful elements. The jack must be cleaned of water, snow, sand, grit, oil, grease or other foreign matter before using.

2.

The jack must be lubricated periodically in order to prevent premature wearing of parts. A general purpose grease must be applied to all

zerk grease fittings, caster wheels, elevator arm, handle base pivot bolts, release mechanism and all other bearing surfaces.

IMPORTANT: any jack found to be defective as a result of worn parts due to insufficient or lack of lubrication is not eligible

for warranty consideration.

MODEL 7752C

(Rev. D)

CAPACITY: 1-1/2 TON

TRANSMISSION JACK