7752C Rev. D

4

rev. 01/23/15

PREVENTATIVE MAINTENANCE (CONT.)

3.

It should not be necessary to refill or top off the reservoir with hydraulic fluid unless there is an external leak. An external leak

requires immediate repair which must be performed in a dirt-free environment by qualified hydraulic repair personnel who are

familiar with this equipment.

IMPORTANT:

In order to prevent seal damage and jack failure, never use alcohol, hydraulic brake fluid or transmission oil in the jack.

Use Chevron Hydraulic Oil AW ISO 32 or its equivalent Unocal Unax AW150.

4.

Every jack owner is responsible for keeping the jack labels clean and readable. Use a mild soap solution to wash external surfaces of the

jack but not any moving hydraulic components. Contact Sunex for a replacement label if your jack's label is unreadable.

5.

Inspect the jack before each use. Do not use the jack if any component is cracked, broken, bent, shows sign of damage or leaks

hydraulic fluid. Do not use the jack if it has loose or missing hardware or components, or is modified in any way. Take corrective action

before using the jack again.

6

. Do not attempt to make any hydraulic repairs unless you are a qualified hydraulic repair person that is familiar with this

equipment. Repairs must be performed by an authorized service center.

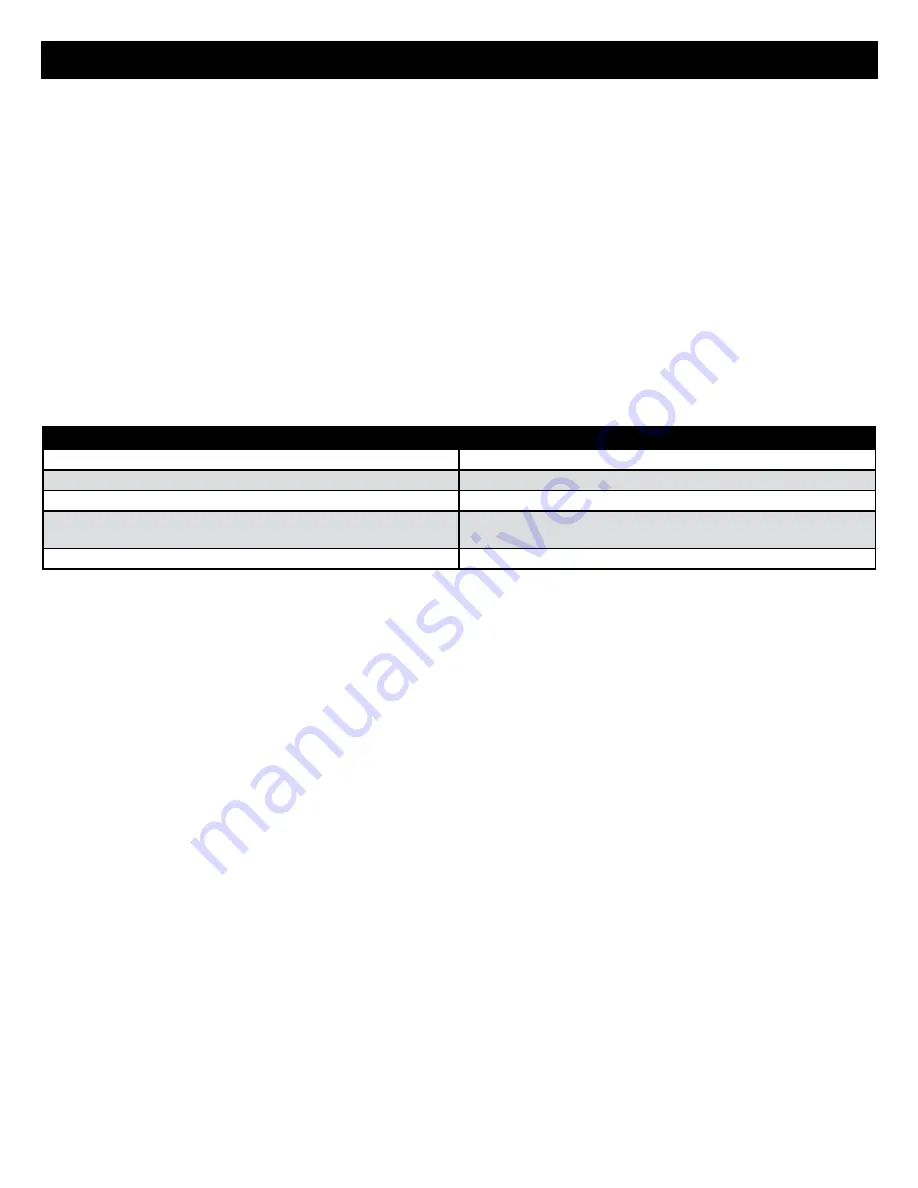

TROUBLESHOOTING

PROBLEM

ACTION

1. Unit will not lift rated load.

Purge air from hydraulic system by following procedure under SETUP.

2. Unit will not sustain rated load or feels “spongy” under rated load.

Purge air from hydraulic system as above.

3. Unit will not lift to full height.

Purge air from hydraulic system as above.

4. Handle tends to raise up while the unit is under rated load.

Pump the handle rapidly several times to push oil past ball

valves in power unit.

5. Unit still does not operate.

Contact Sunex authorized hydraulic service center.

OWNER'S MANUAL