7752C Rev. D

6

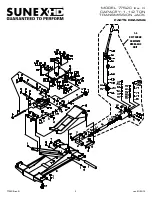

PARTS LIST

MODEL 7752C

(Rev. D)

CAPACITY: 1-1/2 TON

TRANSMISSION JACK

1

RS7752D01

Wheel Assembly/each (incl. #1,2,3)

4

2

Washer

6

3

Nut

6

4

Frame Board Assy.

1

5

Bolt

2

6

Shaft

1

7

Washer

1

8

Rod Link

2

9

Washer

2

10

Saddle Seat

1

11

Shaft

1

12

Washer

4

13

Bracket

1

14

Nut

2

15

Shaft

1

16

Pin

2

17

**

Bolt

9

18

Handwheel

2

19

RS7752D19

Adjustment Rod Assembly/each (incl. #16-19) 2

20 **

Nut

3

21

RS7752D21 Shaft

1

22

RS7752D22

Retaining Ring/each

6

23 **

Nut

2

24 **

Bearing

4

25 **

Nut

2

26

RS7752D26

3" Shaft

1

27

RS7752D27

5.5" Shaft

1

28

Grease Fitting

1

29

Lift Arm Assembly

1

30

Pin

2

31

Shaft

2

32

Rod Link

2

33

Washer

2

34

Rod Link

1

35

Pin

1

1-0

RS7752DHU

Complete Hydraulic Unit

1

1-1

Washer

1

1-2

Washer

2

1-3 *

O-ring

1

1-4

Piston Rod

1

1-5

Piston ring

1

1-6

*

Sealing washer

1

1-7 *

O-ring

1

1-8

Washer

1

1-9

Washer

1

1-10

Body

1

1-11

*

Oil filler plug

1

1-12

Washer

2

1-13

Bolt

2

1-14

Bolt

1

1-15

*

Copper washer

1

1-16

Valve

1

1-17

*

Steel ball 6

2

1-18

*

O-ring

2

1-19

RS7752D119

Release Valve Assembly (incl. 1-19 to 1-21) 1

1-20

Pin

1

1-21

Release Knob

1

1-22

Screw

1

1-23

*

Steel ball 4

1

1-24

Ball seat

1

1-25

*

Spring

1

1-26

Screw

1

1-27

Sealing washer

1

1-28

Screw

1

1-29

*

Spring

1

1-30

*

Steel ball 9

1

1-31

*

Spring

1

1-32

*

Copper washer

1

1-33

Screw

1

1-34

*

Copper washer

1

1-35

Washer

3

1-36

Bracket

1

1-37

Pin

1

1-38

*

Y-ring

1

1-39

*

O-ring

1

1-40

Cylinder Pump

1

1-41

Pump cylinder

1

1-42

*

Dustproof plug

1

1-43

Washer

2

1-44

Pin

2

1-45

Handle

1

1-46

Handle Sleeve

1

3-1

***

Bolt

2

3-2

***

Washer

2

3-3

***

Lock Washer

2

3-4

RS7752D34

Chain/each

2

3-5

***

Nut

2

3-6

***

Bolt

4

3-7

RS7752D37

Bracket/each

2

3-8

Saddle Plate

1

3-9

***

Washer

4

3-10

***

Wing Nut

4

3-11

***

Nut

2

3-12

***

Washer

2

3-13

RS7752D313

Bracket/each

2

3-14

***

Wing Nut

2

3-15

***

Adapter Bolt

2

3-16

***

Chain Hook

2

3-17

Bolt

2

3-18

Board

1

RS7752DLK

Product Label Kit (not shown)

1

*

Available in seal kit, RS7752DSK

** Available in saddle bearing kit, RS7752DSBK (incl. #17 (7), #20 (3), #23 (2),

#24 (4), #25 (2).

*** Available in bolt kit, RS7752DBK

Only index numbers identified by part number are available separately.

Index Part

No. No.

Description

Qty.

Index Part

No. No.

Description

Qty.

Learn more about garage accessories we offer on our website.