9001A:

Parts Breakdown & Operating Manual

4

rev. 04/29/06

FOR BEST PERFORMANCE,

PLEASE BE SURE TO DO THE FOLLOWING

BEFORE USING THIS TOOL

• Tighten the gun to the cup securely with the nut and fitting supplied.

• Be sure to have the proper air pressure at the gun to operate. Proper air pressure for this tool should be

35 PSI for lacquer and 43 PSI for enamel.

• Adjust fluid control screw and spray width adjustment screw to your desired pattern before using on production.

• Clean all parts after use.

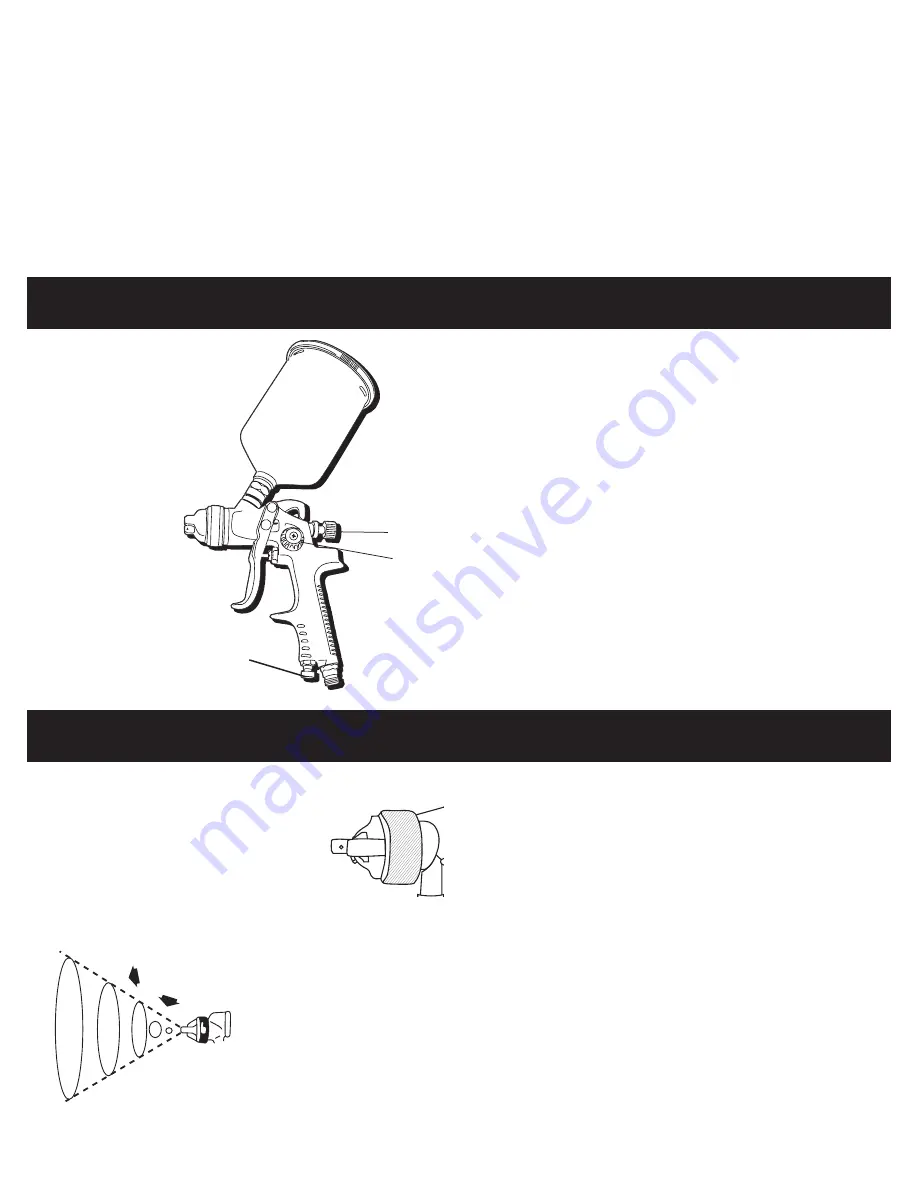

In normal use, the nozzle wings are

horizontal as shown here. This provides a

vertical fan-shaped pattern which gives

maximum, even material coverage as the

gun is moved back and forth parallel to the

surface being finished.

Spray pattern may be infinitely adjusted

from round to flat.

Set inlet pressure at no more than 43 PSI. For optimum

performance, some materials may spray better at PSI

ratings below 43 PSI. If unsure, always test at PSI ratings before

using on final production. Try spray. If it is too fine, decrease

the air pressure or open fluid control screw. If the spray is too

thick, close the fluid control screw. Regulate the pattern width

and repeat adjustment of spray as needed.

®

®

®

ADjUSTMENTS

SPRAyING

Fluid control screw

Turn right to decrease flow, left to increase.

Spray width adjustment screw.

Turn right for round, left for fan.

Air Flow Adjustment Screw