SX275B

4

Rev. 05/02/02

Nipple

Operating Instructions • Warning Information • Parts Breakdown

Air Supply...

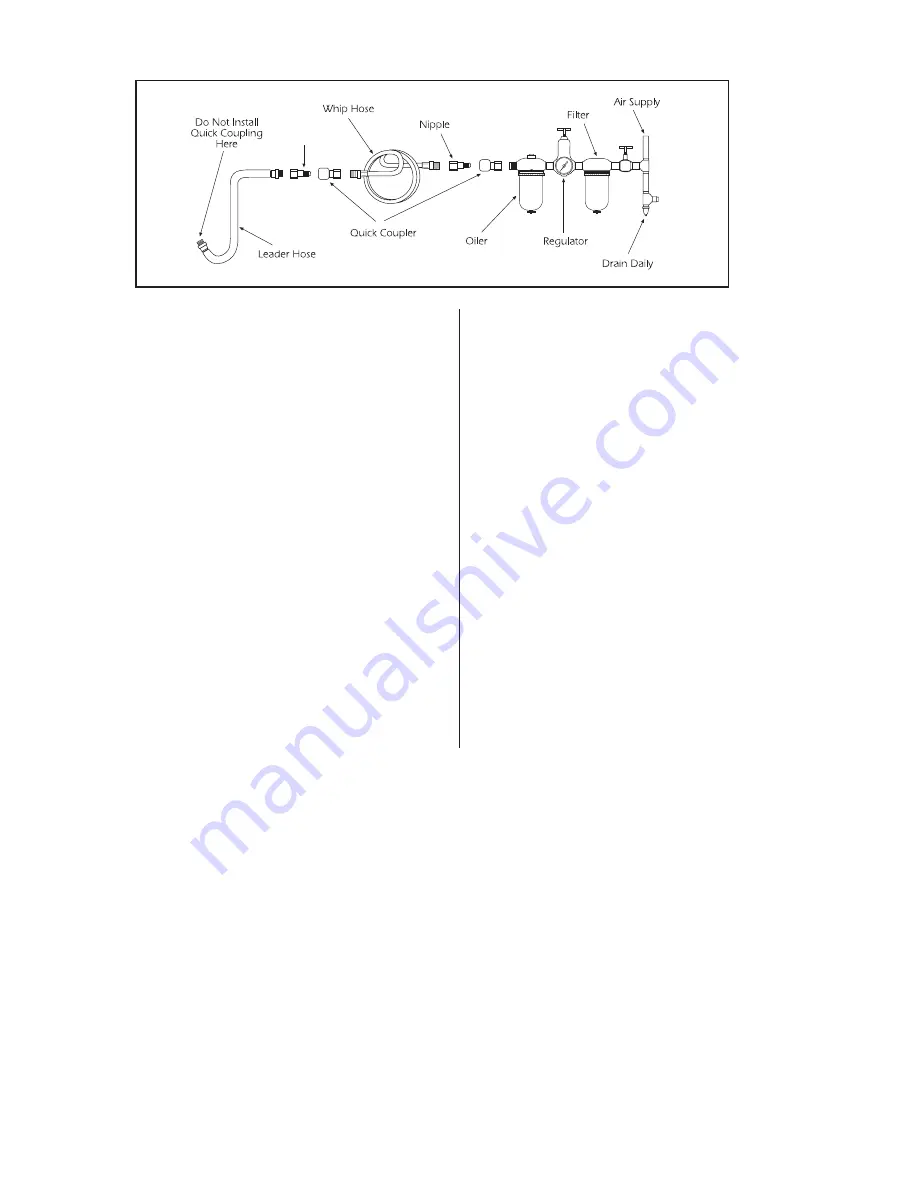

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measures 90 PSI

at the tool while running free. Higher pressure (over 90 psig;

6.2 bar) raises performance beyond the rated capacity of the

tool which will shorten the tool’s life because of faster wear and

could cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water

in the air line will cause damage to the tool. Drain the air tank

daily. Clean the air inlet filter screen on at least a weekly

schedule. The recommended hookup procedure can be

viewed in the above figure.

The air inlet used for connecting air supply, has standard 1/4"

NPT. Line pressure should be increased to compensate for

unusually long air hoses (over 25 feet). Minimum hose diameter

should be 3/8" I.D. and fittings should have the same inside

dimensions and be tightly secured.

Lubrication...

Lubricate the air motor daily with quality air tool oil. If no air

line oiler is used, run a teaspoon of oil through the tool. The oil

can be squirted into the tool air inlet or into the hose at the

nearest connection to the air supply, then run the tool.

Operation...

Always place a chisel in the hammer and hold the tool

down to the work before operating. Damage to the tool

or the retainer may result if this precaution is not followed.

The chisel retainers are not designed for complete safety

against accidental release of cutters or hammers. To avoid

injury, the throttle must never be depressed unless the

chisel is held firmly against the work place. When tool is

not in actual use, the chisel must be removed. During

operation, safety goggles should always be used to guard

against flying rust and chips. When using tool, regulate

the speed so that the chisel is not being driven out of the

cylinder. If piston is allowed to strike the cylinder wall,

internal damage will result.

To change chisel, pull back on spring hook and insert

chisel. Release spring hook.

To regulate air, turn air regulator knob out for maximum

air pressure and in for minimum.

Limited Warranty...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS

®

BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools

®

branded products which fail to give satisfactory service due to defective

workmanship or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product. This

product carries a ONE-YEAR warranty. During this warranty period, Sunex Tools will repair or replace at our option any part or unit which proves

to be defective in material or workmanship.

Other important warranty information...

This warranty does not cover damage to equipment or tools arising from alteration, abuse, misuse, damage and does not cover any repairs or

replacement made by anyone other than Sunex Tools or its authorized warranty service centers.The foregoing obligation is Sunex Tools’ sole

liability under this or any implied warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note:

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you. Return equipment or parts to Sunex Tools, or an authorized warranty service center, transportation prepaid. Be

certain to include your name and address, evidence of the purchase date, and description of the suspected defect.

If you have any questions about warranty service, please write to Sunex Tools. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state. Repair kits and replacement parts are available for many of Sunex Tools products regardless of whether

or not the product is still covered by a warranty plan.

Shipping Address:

Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

Mailing Address:

Sunex Tools • P.O. Box 4215 • Greenville, SC 29608