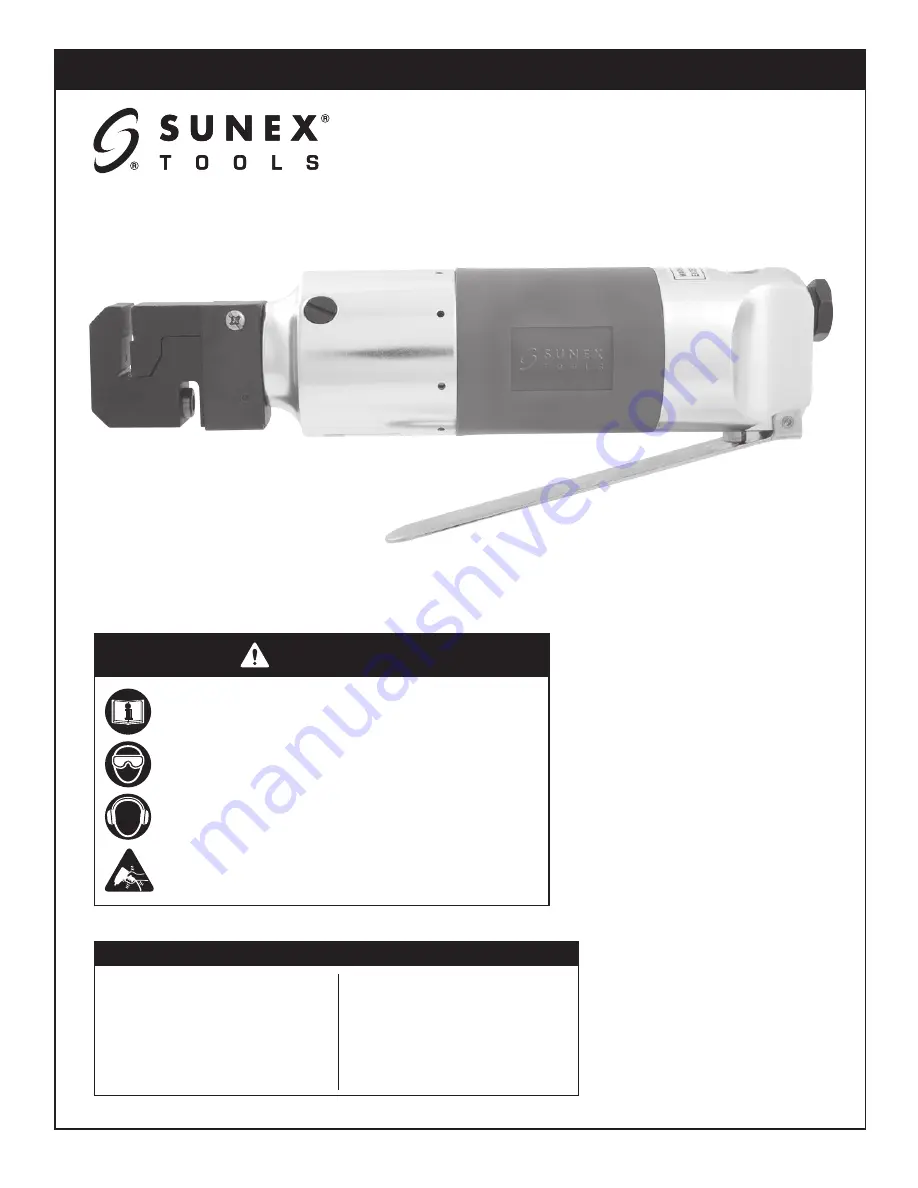

SX280:

Parts Breakdown & Operating Manual

10/25/11

Punch Hole ..................3/16" (9.525mm)

Cutting Capacity:

Steel .................................0.05" (1.2mm)

Aluminum .........................0.08" (2.0mm)

Weight .......................... 2.9 Lbs. (1.3 kg)

Length .............................9.84" (250mm)

SX280

3/16" (5MM)

PUNCH/FlaNge

Tool

Average Air

Consumption ...... 0.25 CFM (7.08 l/min)

Air Inlet .....................................1/4" NPT

Minimum

Hose Size .....................3/8" I.D. (10mm)

SPECIFICATIONS

AVOID PROLONGED EXPOSURE TO VIBRATION

WEAR HEARING PROTECTION

ALWAYS WEAR SAFETY GOGGLES

ALWAYS READ INSTRUCTIONS BEFORE

USING POWER TOOLS

WARNING

Operating Instructions • Warning Information • Parts Break down