5

6

6.Mechanical Part Installation and Adjustment

6.1. Installation of cabinet

Please select the correct type of barrier ate according the specifications

of the place, and then fix the barrier cabinet with expansion bolts.

(refer to Figure 3)

6.2. Spring selection, installation and adjustment

The barrier gate is well-adjusted before delivery. If need to cut the

boom shorter, please re-adjust the spring balance to ensure the

smooth operation of the barrier. Also you can adjust the speed to

slower or faster when arm made longer or cut shorter

6.2.1. Spring selection

The length of spring prevails in kind, designing change without

notice. The spring selection please refer to the spring selection

table in the

Appendix I

of the Manual or which sticks on the door

of the barrier cabinet.

6.2.2. Spring installation, dis-assembly and replacement

Dismantlement steps: Keep the boom at vertical (open) position, see

figure1, loosen the spring fixing nuts on the bottom of the spring by

adjustable or 8

th

spanner, unscrew the fastening wing nuts in the

bottom of the spring by manual, then take off the spring.The steps for

installation and dis-assembly the spring are the opposite.

6.2.3. Spring force adjustment

When power off, adjust the springs balance to make sure the arm will stay

in the angle 45-60 degrees towards the horizontal, and not going down or

going up, which mean the spring force is well balanced.

7.

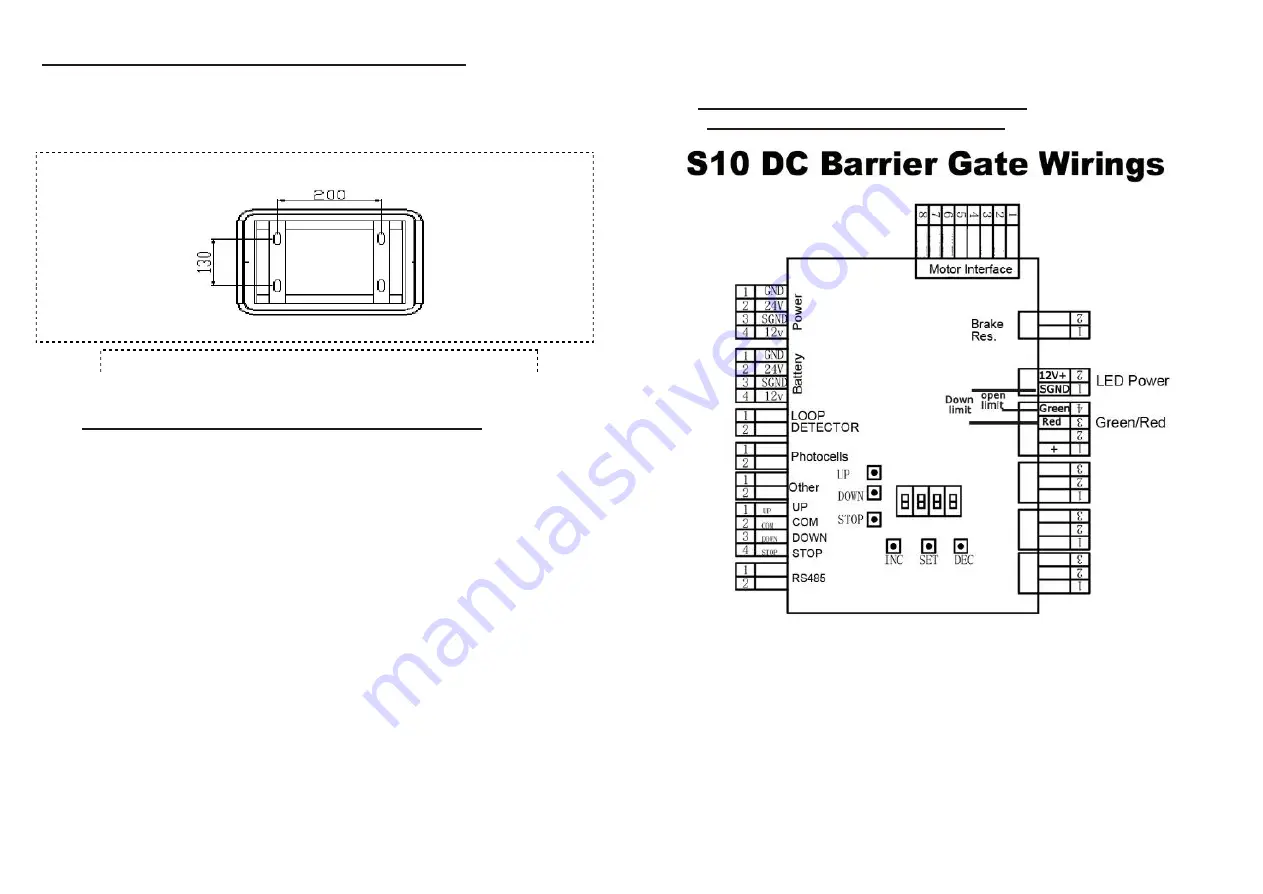

Controller Wiring and Instructions

7.1.

Controller interface explanations

(Figure 4)

All the electrical connections are done before delivery. The necessity

is to connect the power and grounding connection. Explanations and

instructions for the main function interfaces and indicator light is as

following:

7.1.1. 220V/110V Power supply DIP switch in power supply:

This barrier motor supports 24VDC power input, and controller support

12V DC power input. There are two power supplies, one is 220V or

110V input(by DIP switch) while output is 24V DC, and another input is

110~220V AC while output is 12V DC. So one is for motor power

supply, and another is for control board power supply. the DIP switch is

Expansion Bolts

Press bars

(According to the supplementary size)

(According to the supplementary size)

(Figure 3)