44

Step 3

Select the port (COM1/COM2/COM3/NET) that the meter is actually connected to in the

“Port”.

Step 4

Select “Others” option in the “Device Model”.

Step 5

Select “Custom” option in the “Configuration Method”. Click “Next” to enter

“Configure Measuring Point” the interface.

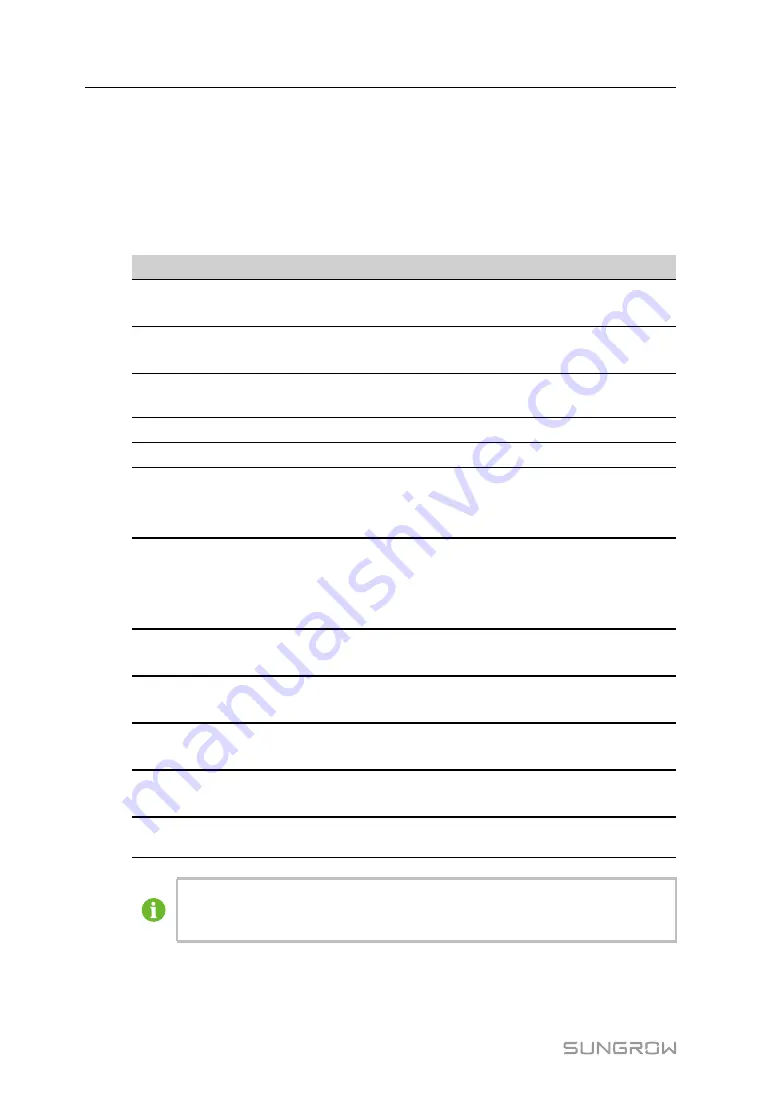

Table 9-1

Parameter description

P

Pa

arra

am

me

ette

err

D

De

essc

crriip

pttiio

on

n

Byte Order

Refer to the communication protocol of the meter,

parse the order of the read byte stream

PT Transformation Ratio

Refer to the communication protocol of the meter,

voltage transformation ratio

CT Transformation Ratio

Refer to the communication protocol of the meter,

current transformation ratio

Beginning Address

The beginning address of the device

Quantity of Device

The number of the meter

Debug Address

The device address to be read when click “Read-

Back”, the range is [(“Beginning Address”), (“-

Beginning Address” + ”Quantity of Device”-1)]

Modbus Address

Refer to the communication protocol of the meter, the

address of Modbus communication protocol, priority to

select the register address corresponding to the data

type of “Float”

Register Type

Refer to the communication protocol of the meter, the

register type of the corresponding measuring point

Data Type

Refer to the communication protocol of the meter, the

data type of the corresponding measuring point

Read Type

With or without framing when send messages at this

point, recommend to choose continuous type

Coefficient

Refer to the communication protocol of the meter, the

coefficient that multiplied the value of the data read

Read-back Value

The value of the selected measuring point read when

clicking "Read-back”

The user can select up to 21 objects for setting. Their corresponding

parameters such as Modbus address please refer to the user manual of the

connected meter.

Step 6

Select the points to be measured, click “Read-back” to read the information from the

meter in real time to check the correctness of parameter setting.

User Manual