System Manual

26

** The bolt specification may vary with different projects.

Specifically, refer to the final

deliveries.

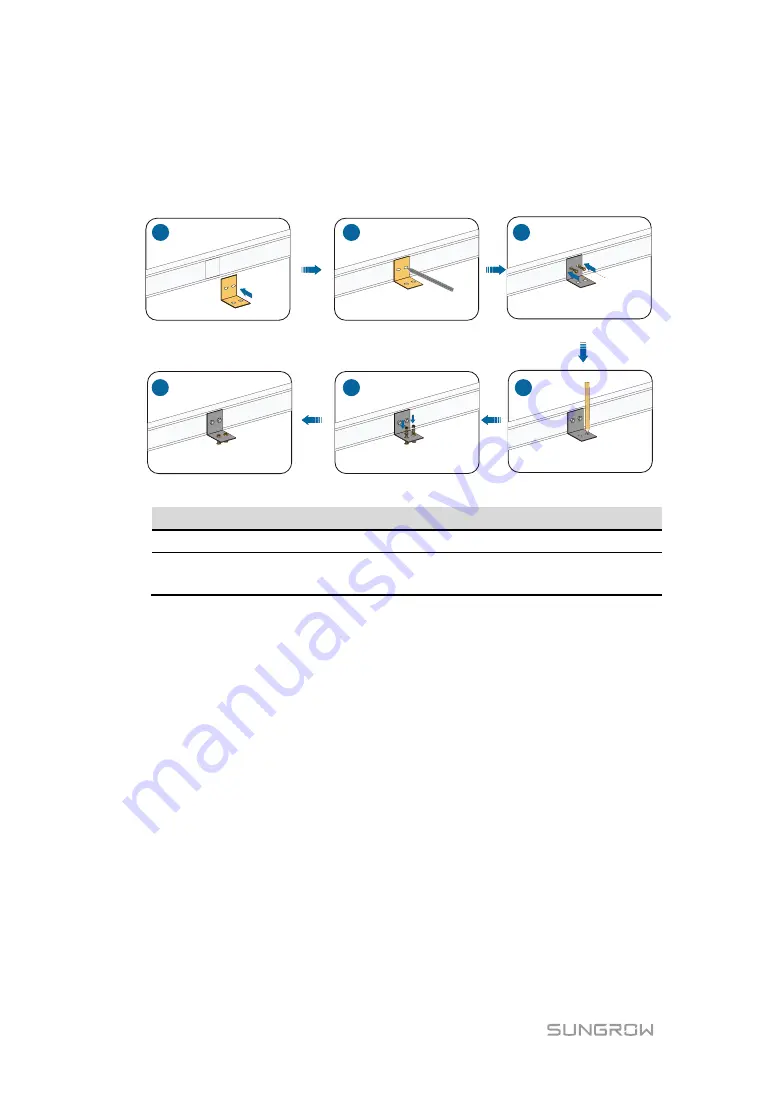

Installation Method

5

4

3

2

1

6

Screw

Torque (N·m)

M12x35

60~70

M16x50

M16X150

119~140

Other Precautions

A drainage system should be designed on the installation site to prevent the MV

Station from being immersed in water during heavy rainfalls.

Do not plant any trees near the MV Station installation site to prevent the damage of

the MV Station caused by tree leaves or stems.

5.5

Removing Sealing Plates, Sealing Tapes and

Fasteners

The sealing plates, sealing tape and fastens are attached to the enclosure of the MV Station

to prevent moisture penetration during transportation.

Remove the sealing plates, sealing tapes and fastens before commissioning.

Summary of Contents for MVS6250

Page 2: ......