7

Operation

m

WARNING!

Before using the log splitter, review the

instructions below and all safety information. Failure to follow

these instructions may result in property damage or injury to

the operator or bystanders.

m

WARNING!

Before the initial operation, the bleed screw

should be adjusted to allow air to go in and out of the oil tank.

(loosen three to four turns). Airflow should be detectable during

operation. To avoid leaking oil close the bleed screw when

moving the machine.

Important! Failure to open the bleed screw during operation

will result in permanent damage to the log splitter.

m

WARNING!

Do not adjust the max. pressure limiting

screw. This was set at the factory so the log splitter works

under the maximum pressure limit of 5 tons. Tampering

with the screw will result in hydraulic pump failure. Only

a professional mechanic shall adjust the max. pressure

limiting screw.

Splitting Operation

Follow these instructions to operate the log splitter:

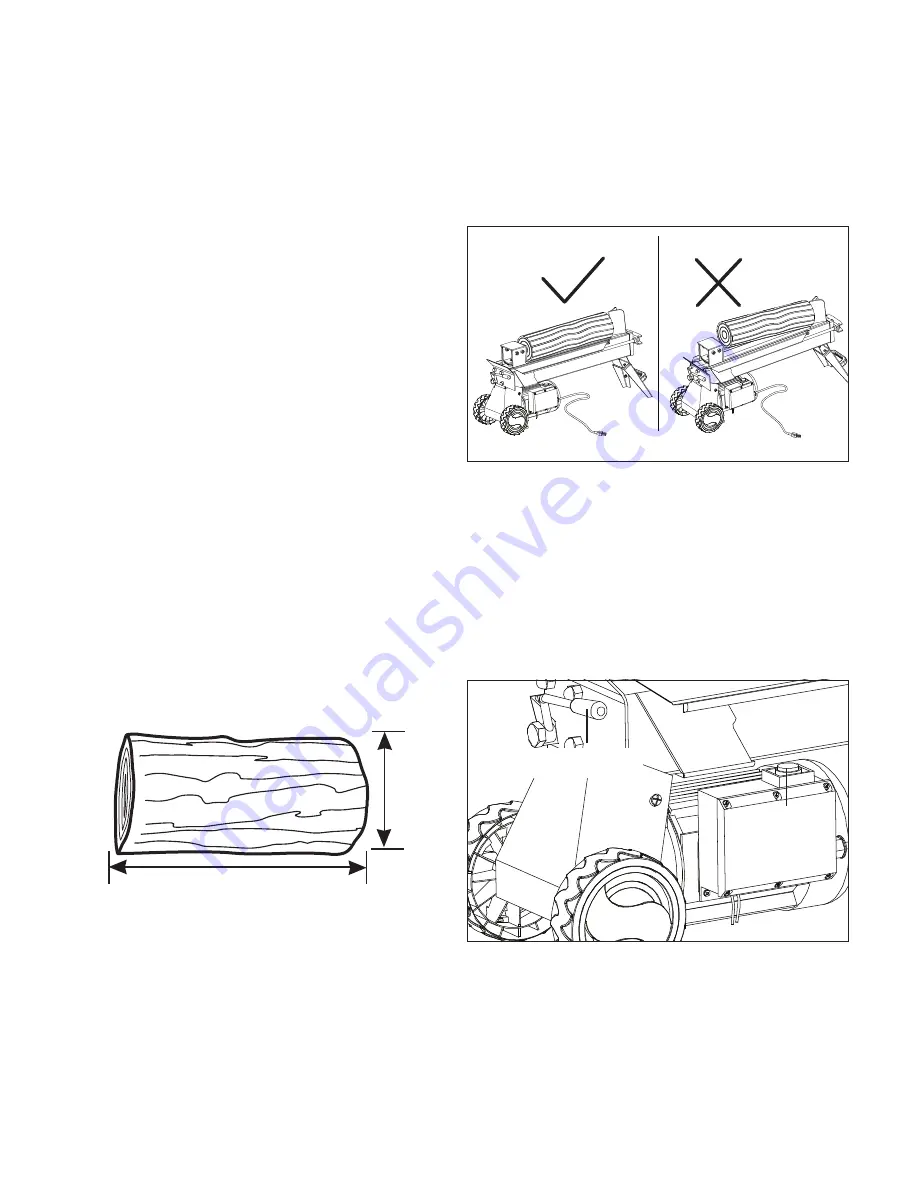

1. Ensure all logs meet the proper size requirements

[(max log diameter: 10 in. (25.4 cm); max log length:

20.5 in. (52 cm)].

IMPORTANT! Logs vary in hardness and structure. Small

logs with knots or harder wood may be more difficult to

split. Larger logs with less hardness may not be difficult to

split. Do not force the log splitter if the log fails to split on

the first attempt.

2. When loading or positioning a log, always handle the bark

side; never handle the ends. Never place your hands or

body parts between the log and the splitter.

3. Make sure all moving parts is completely stop. Never load

or unload logs while the log pusher is moving.

4. Check that bleed Screw is open.

5. Load the log lengthwise into the unit between the wedge

and the log pusher. Be sure that the split will be along the

grain. Check to make sure the log is fixed stably.

m

WARNING!

Always set logs firmly on the log retaining

plates and the log rail. Make sure logs will not twist, rock or

slip while being split. Do not force the blade by splitting the

log on the upper part. This will break the blade or damage the

machine (Fig. 3).

m

WARNING!

Never load or unload logs while the log

pusher is moving.

6. Plug the appliance cord into an appropriate power outlet.

7. Engage the log pusher by using your left hand to push the

hydraulic control lever and your right hand to push the

On/Off switch (Fig. 4).

NOTE: This log splitter is equipped with ZHB control

system, which requires both the On/Off switch and the

hydraulic control lever to be engaged simultaneously to

start the machine.

8. The log pusher will move forward and the log will be split

by the splitting wedge.

10 in. (25.4 cm)

20.5 in. (52 cm)

Fig. 3

Fig. 4

Hydraulic control

lever

On/Off switch

Summary of Contents for LJ602E

Page 12: ...sunjoe com ...