10

MAINTENANCE INSTRUCTIONS

This is general information for daily, weekly and monthly maintenance to be performed on your bike.

Version 3.2

DAILY MAINTENANCE

After each exercise session, wipe down all the

equipment: seat, frame, handlebars. Pay

special attention to the seat post, handlebar

post and belt/chain guard. Sweat is very

corrosive and may cause problems that

require parts replacement later.

1.

Get on the bike and engage the drive

train.

2.

Pay attention to any vibrations felt through

the pedals. If you feel any vibrations, you

may need to tighten the pedals, bottom

bracket, or adjust the drive belt/chain

tension.

3.

Use a wrench to tighten the pedals until

they are secure.

MONTHLY MAINTENANCE

1. Check if all hardware is secure, such as:

water bottle holder, flywheel nuts, belt/chain

guard bolts, brake caliper lock nuts and brake

caliper tension rod nuts.

2. Inspect the brake tension rod for signs of

wear such as missing threads. Clean and

lubricate the brake tension rod.

3. Clean and lubricate the seat post, handlebar

post and seat slider. Remove any build up of

foreign material.

WEEKLY MAINTENANCE

1. Inspect moving parts and tighten the

hardware.

2. Inspect pull pin frame fittings to make sure

the fittings are snug. Loose frame fittings

may strip out threads over time and cause

extensive damage.

3. Clean and lubricate pop pin assemblies.

Pull on the pin and spray a small amount

of lubricant onto the shaft.

4. Tighten the seat hardware to make sure

the seat is level and centered.

5. Brush and treat the resistance pads.

Remove any foreign material that may

have collected on the pads. Spray the

pads with silicone lubricant. This helps to

reduce noise from friction between the

pads and the flywheel.

6. Visually inspect the bottom bracket, toe

clips and toe straps. If any of them are

loose or disconnected, attach and tighten.

LEATHER BRAKE PAD CARE (If Applicable)

1. Perform this maintenance when the brake

pad is first installed and for the life of the

brake pad. Following these simple guidelines

can increase the life of your brake pads.

2. Some brake pad assemblies are pre-

lubricated. Squeeze the brake pad. If

lubricant is released, then the pad has been

pre-lubricated.

3. If the brake pad is dry, then coat the brake

pad with 3-n-1 oil. Brush the leather with a

clean, wire bristle brush, and then apply the

oil. The oil should be allowed to soak in to the

pad. Repeat 4-5 times until the pad is

saturated, but not dripping with oil. When the

pad is saturated, it will no longer absorb oil.

4. Inspect the brake pad weekly and lubricate if

needed. The pad should not have a glazed

appearance. If the pad appears glazed, then

brush it with wire brush and apply lubricant

as needed. If any of the sponge padding is

showing through the leather pad, the brake

pad should be replaced.

Version

:

3.2

Summary of Contents for SF-B1421

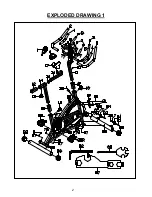

Page 3: ...2 EXPLODED DRAWING 1...

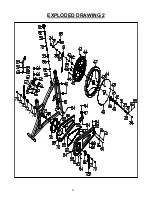

Page 4: ...3 EXPLODED DRAWING 2...