5

ASSEMBLY INSTRUCTIONS

#89 S14 S17 1PC

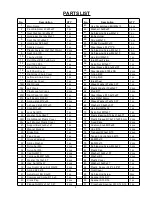

STEP 1:

Attach

Rear Stabilizer

(No. 3)

to

Main Frame

(No. 1)

using 2

Carriage

Bolts

(No. 36)

, 2

Washers

(No. 37)

and 2

Cap Nuts

(No. 35)

. Tighten

with

Spanner (No. 89)

.

Attach

Front Stabilizer (No. 2)

to

Main Frame

(No. 1)

using 2

Carriage

Bolts

(No. 36)

, 2

Washers

(No. 37)

and 2

Cap Nuts

(No. 35)

. Tighten

with

Spanner (No. 89)

.

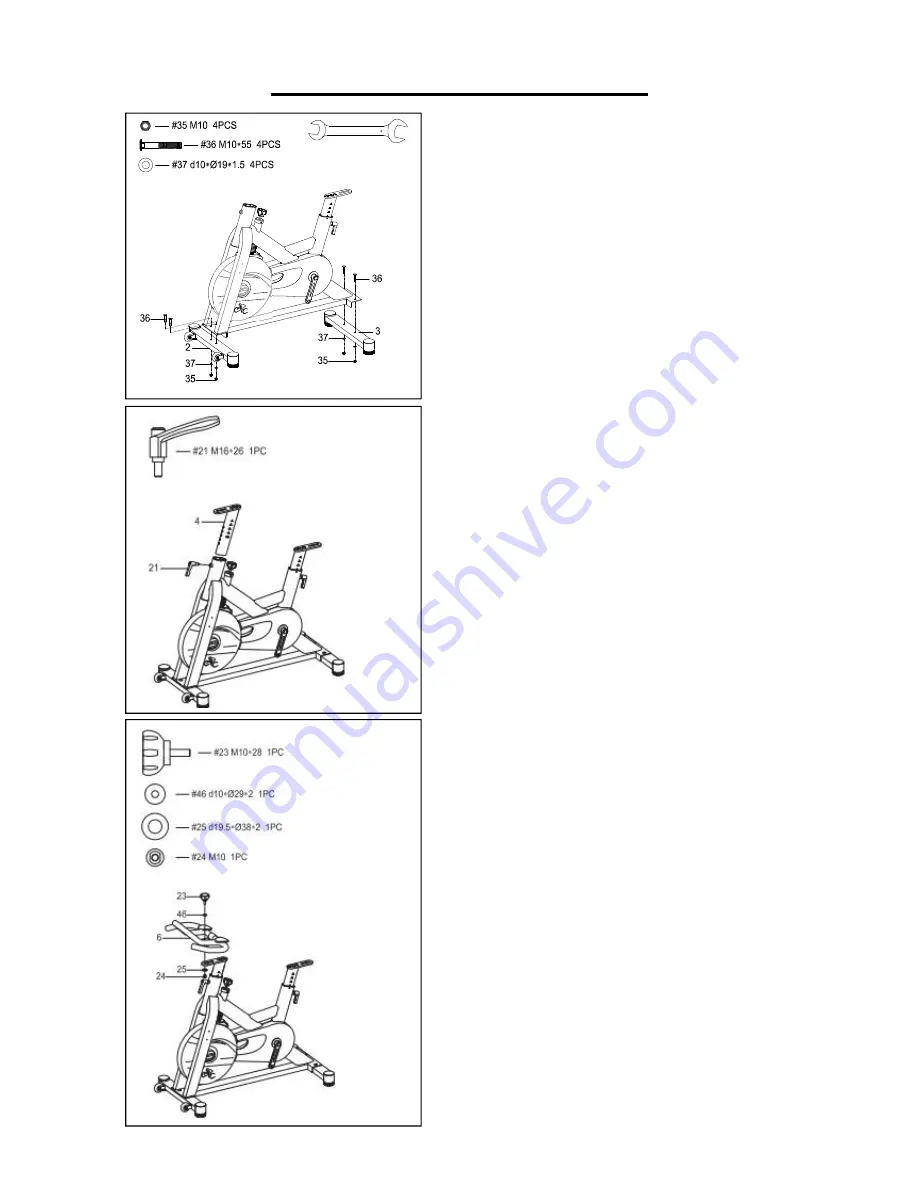

STEP 2:

Insert

Handlebar Post (No. 4)

into

Main Frame

(No. 1)

and fix with

Spring Knob (No. 21)

.

STEP 3:

Secure the

Handlebar (No. 6)

onto the

Handlebar Post (No. 4)

using

Knob

(No. 23)

,

Washer (No. 46)

,

Washer

(No. 25)

and

Lock Nut (No. 24)

.

Summary of Contents for SF-B1714

Page 3: ...2 EXPLODED DRAWING 16 88 14 82 72 43...

Page 5: ...4 HARDWARE PACKAGE...