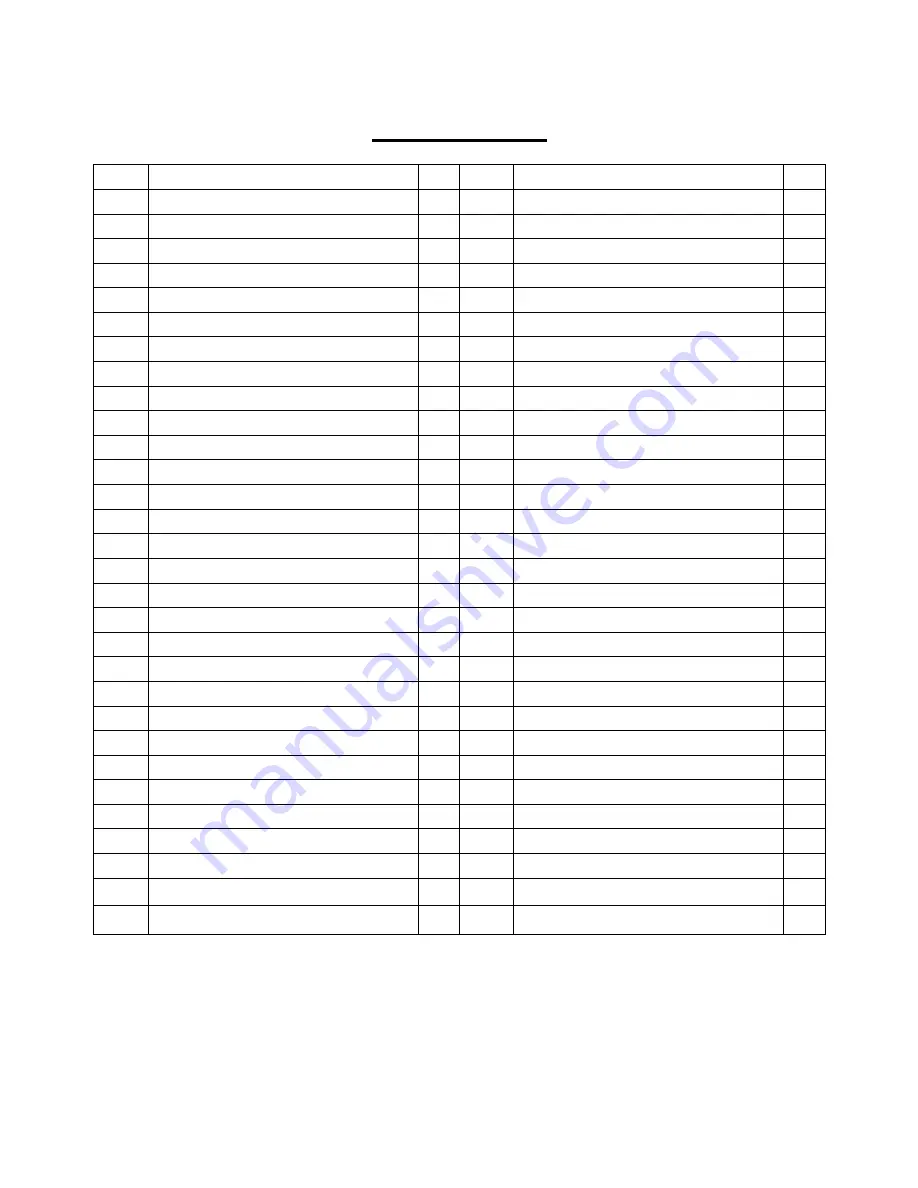

3

PARTS LIST

No.

Description

Qty No.

Description

Qty

1

Computer

1 31

Bolt M8*65*30*S14

2

2

Middle handlebar

1 32

Spacer 14*8.3*48

2

3

Foam grip 23*5*445

2 33

Alloy wrap 1 32*3*28*16*14

4

4

End cap 25*16

2 34

Bolt M10*42*20*S17

2

5

Washer d6*Φ12*1

2 35

U shape plate

2

6

Screw ST4*19

2 36

Arc washer d6*Φ20*1.5*R30

1

7

Handle pulse sensor *25

2 37

Washer d8*Φ16*1.5

6

8

Screw M8*30*S6

2 38

Nylon nut M8*H7.5*S13

6

9

Handle pulse wire

1 39

Wave washer d19*Φ25*0.3

2

10

Upper sensor wire

1 40

Hinge bolt R Φ16*89*23*1/2*S8

1

11

Grommet 12*11*Φ3

1 41

End cap J40*25*15

4

12

Foam grip 26*5*510

2 42

Clamp cover

1

13L/R Handlebar L/R

2 43L/R Pedal

2

14

End cap 28*32*50

2 44

Bolt M10*50*13*S17

2

15

Screw M5*10

2 45

Hinge bolt L Φ16*89*23*1/2*S8

1

16

Bushing 32*25*L83

2 46

Alloy bushing 28*4*Φ24*12*16.1 4

17

Bolt M8*40*20*S14 Grade A

6 47

Link connector combination

2

18

Arc washer d8*Φ20*2*R16

2 48

Nylon nut R 1/2*20*H8*S19

1

19

Nut M8*H16*S13

6 49

Spring washer 1/2”

2

20

Long spacer 32*19.2*75.5

2 50

Nylon nut L 1/2*20*H8*S19

1

21

Alloy wrap 2 *32

4 51

End cap 50*45.5*64.5

2

22

Washer d8*Φ32*2

2 52A Tension control

1

23

Spring washer d8

4 52B Tension cable

1

24

Bolt M8*16*S14

2 53

Screw M8*16*S6

4

25L/R Swing rod L/R

2 54

Alloy bushing 18*3*14*7*10.1

4

26

End cap 50*61*50

2 55

Connecting rod

2

27

Front stabilizer

1 56

Washer d10*Φ20*2.0

4

28

Carriage bolt M8*60*20*H5

4 57

Tension wire

1

29

Arc washer d8*Φ20*2*R30

8 58

Lower sensor wire

1

30

Screw M5*16

1 59

Main frame

1