- 5 -

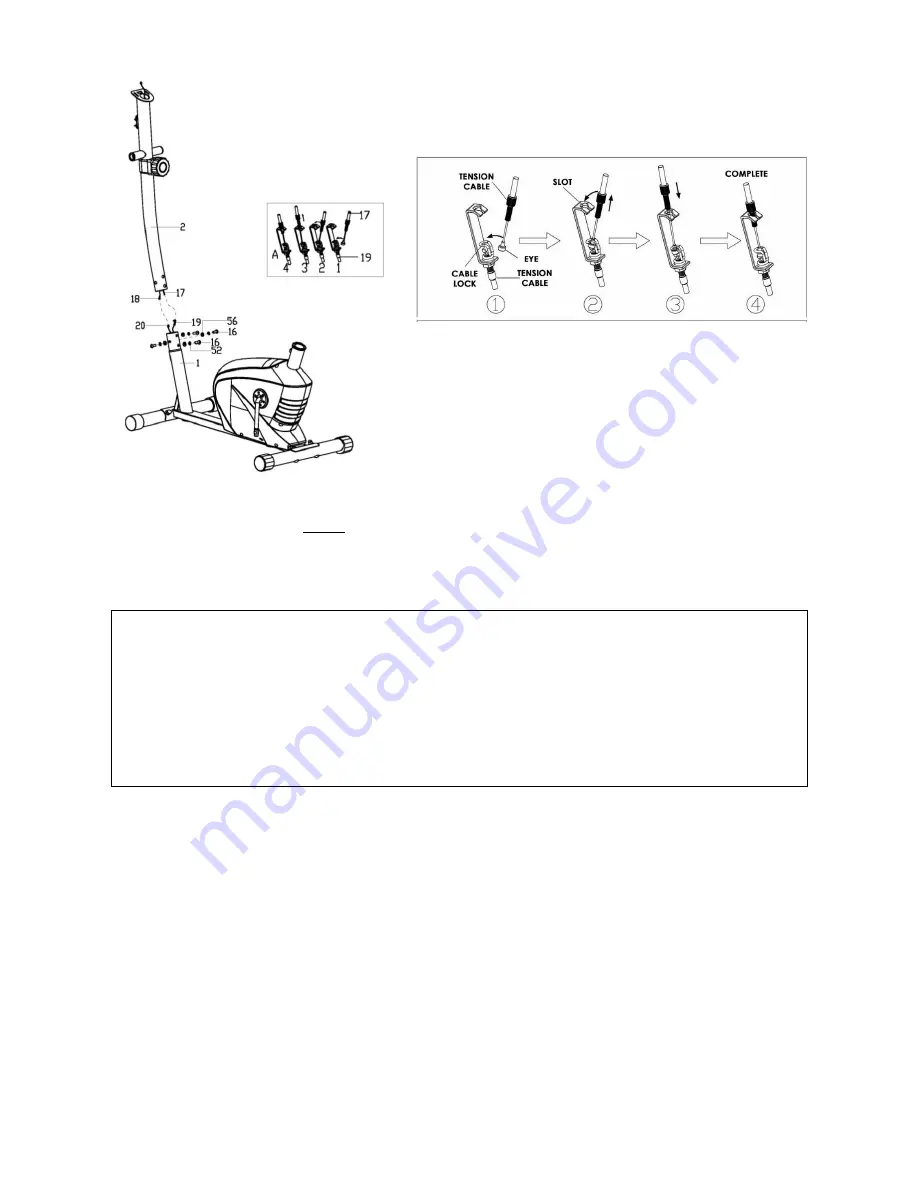

Step 3:

Important:

Please read entire page before starting this step and note all cautions.

A:

Attach the

Swing Bar (6L)

on the long axle of the

Handlebar Post (2)

with

Hex Bolt

(24)

,

Spring Washer (52)

,

Flat Washer (25)

,

Waveform Washer (54)

and

Long Axle

(27)

as shown. Do not tighten them all the way yet.

Caution! Part 38 is labeled L for LEFT and R for RIGHT. Do not try to install the Left Bolt on

the Right Crank and vice versa. Make sure to turn 38L

counterclockwise

to tighten,

and 38 R

clockwise

to tighten.

Part 38L and 42L have reverse threading. Turn 38L and 42L

counterclockwise

to tighten.

Keep the

Right and Pedal Support Bolt (38 R/L)

at a 90° angle to the

Crank (22)

. The

Right and Left Pedal Support Bolt must be perfectly straight as it goes through the Pedal

Support to the Crank. If the Pedal Support is connected to the Crank at an angle,

permanent damage to both the Bolt and Crank may occur.

B:

Attach

Pedal Support (5L)

to the

Crank (22)

using

Pedal Support Bolt (38L)

,

Waveform Washer (62)

,

Spring Washer (41)

and

Nylon nut (42L)

as shown. Do not

tighten them at this time.

C:

Connect

Swing Bar (6L)

with

Pedal Support (5L)

using

Hex Bolt (30)

,

Flat Washer

(31)

and

Nylon Nut (32)

. Now, tighten the

Hex Bolt (24) (30)

and

Nylon Nut (42L)

.

Cover with the

Nut Caps

(23) (57) (43) (36)

.

D:

Fix the

Pedal Support (5R)

and

Swing Bar (6R)

to

Crank (22)

and

Handlebar Post (2)

in the same way, but make sure to turn clockwise to tighten.

E:

Fix the

Pedal (10L/R)

to the

Pedal Support (5L/R)

with

Hex Bolt (33)

,

Flat Washer (34)

and

Nylon Nut (35)

.

Summary of Contents for SF-E3628

Page 3: ...2 EXPLODED DIAGRAM...

Page 7: ...6...