Main Breaker

Utility Meter

L2

L1

CT

CT

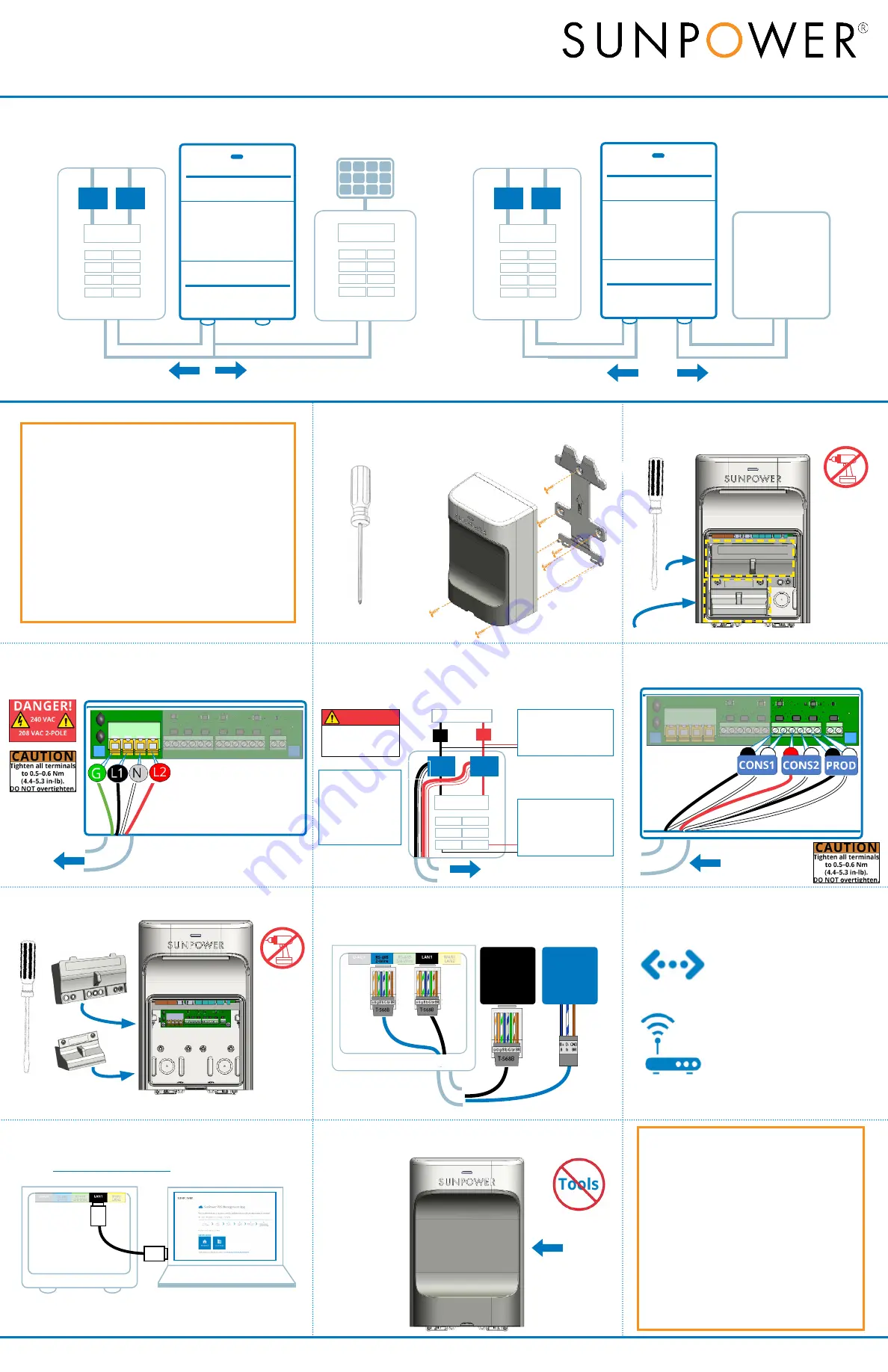

3. Wire PVS6 power

Use copper conductors only, with min. 75

°

C temp. rating.

Install a

dedicated 240 or 208 VAC circuit. Land wires in J2 terminals: green to

GND; black to L1; white to N; and red to L2.

4. Install consumption CTs

Refer to Section 3 on the other side for complete CT installation instructions.

Place CTs around incoming service conductors: L1 CT (black and white wires)

around Line 1 and L2 CT (red and white wires) around Line 2.

6. Replace PVS6 wiring covers

Use screwdriver to replace AC wiring covers over AC power wires.

5. Wire consumption CTs

Land wires in J3 terminals: L1 CT and L2 CT wires

to corresponding CONS L1 and CONS L2.

7. Connect DC inverter communication

If DC inverter is installed, connect communication from DC inverter to

the PVS6. No additional connection is required for AC modules.

Never run

communication cable and

AC wiring in same conduit

SMA US-40

Inverter

Port A or B

SMA US-22

Inverter

2

(B)

7

(b)

5

(BR)

10. Replace PVS6 cover

Snap the enclosure cover onto the PVS6.

8. Connect PVS6 to the internet

Connect to customer’s internet with either:

Customer’s Wi-Fi

Connect during commissioning

with network and password.

Ethernet Cable

From PVS

6

LAN2 to customer’s

router (recommended method).

9. Commission with PVS Management App

Turn off laptop Wi-Fi, connect Ethernet cable from PVS6 LAN1 to

laptop, open latest Chrome or Firefox, type

www.sunpowerconsole.com

, and follow instructions.

https://www.sunpowerconsole.com

PVS6 Quick Start Guide

Follow these instructions to install, configure, and commission the PV Supervisor

6 (PVS6) to begin receiving monitoring data.

Refer to the

PVS6 Installation

Instructions

on the other side for the complete instructions.

CT

CT

Main Service Panel

PVS6 Connection Diagram: DC Inverter Site

\

DC Inverter

Wire PVS6 power and CTs into

main service panel

Wire communication

from PVS6 to inverter

Wire PVS6 into AC

module subpanel

Wire CTs into main

service panel

AC Module Subpanel

CT

CT

Main Service Panel

PVS6 Connection Diagram: AC Module Site

AC Module Array

From CTs around

service conductors

Load-Side System:

Solar output

installed on breaker

in service panel or

downstream of CTs

.

Line-Side System:

Solar output

installed

on line-side tap or

upstream of CTs

.

To PVS6

To 15 A or 20 A

dual-pole breaker

Routing wire and cable:

• Fill all conduit openings in the enclosure with

components rated NEMA Type 4 or better

to maintain the integrity of the enclosure’s

environmental system.

•

Drill extra 0.875

”

(22 mm) or 1.11

”

(28 mm) conduit

openings, if required, with step drill (

do not

use

screwdriver or hammer).

•

Use only the provided conduit openings or drillout

locations and never cut holes in the top or sides of

the enclosure.

•

Never run inverter or Ethernet communication cable

in the same conduit as AC wiring.

•

CT and AC wiring may be run in the same conduit.

Note:

For sites with SMA US-40 DC inverter, connect Ethernet

cable from laptop to port A or B in the last (or only) inverter.

PVS6 Installation Instructions and Quick Start Guide

531566 RevA

Copyright 2018 SunPower Corporation

2 of 2

Hazardous voltage

Use appropriate PPE and

turn off power to the

service panel.

DANGER!

SUNPOWER

PVS6

SUNPOWER

PVS6

Remove lower cover first

2. Remove all PVS6 covers

Use flathead screwdriver to carefully remove the

enclosure cover. Use Phillips to remove the AC wiring

covers.

1. Mount the PVS6

Mount the PVS6 bracket to the wall using hardware that supports 6.8 kg

(15 lb); use Phillips screwdriver to secure the PVS6 to the

bracket using the two provided screws.

Use only UL

Listed, double-

insulated, XOBA

CTs with the

PVS6.

•

Always open or disconnect circuit from power-

distribution system (or service) of building before

installing or servicing current transformers (CTs).

•

The CTs may not be installed in equipment where they

exceed 75% of the wiring space of any cross-sectional

area within the equipment.

•

Restrict installation of CT in an area where it would

block ventilation openings.

•

Restrict installation of CT in an area of breaker arc

venting.

•

Not suitable for Class 2 wiring methods.

•

Not intended for connection to Class 2 equipment

•

Secure CT, and route conductors so that they do not

directly contact live terminals or bus.

•

WARNING!

To reduce the risk of electric shock, always

open or disconnect circuit from power-distribution

system (or service) of building before installing or

servicing CTs.

•

For use with UL Listed Energy Monitoring Current

Sensors rated for Double Insulation.

Warning!

To protect against risk of electrical shock reinstall

the AC wiring covers before reenergizing the equipment.