Sunpro is a registered trademark of Snap-on Corporation

used under license by SPX Corporation.

1-800-228-7667

0002-000-3113

FULL ONE (1) YEAR WARRANTY

Sunpro, 15825 Industrial Parkway, Cleveland, Ohio 44135, warrants to the

user that this unit will be free from defects in materials and workmanship for

a period of one (1) year from the date of original purchase.

Any unit that fails within this period will be repaired or replaced at Sunpro’s

option and without charge when returned to the Factory. Sunpro requests

that a copy of the original, dated sales receipt be returned with the unit to

determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or

improper or unreasonable use. Expendable items, such as batteries, fuses,

lamp bulbs, flash tubes are also excluded from this warranty.

Sunpro DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUEN-

TIAL DAMAGES FOR BREACH OF ANY WRITTEN WARRANTY ON THE

UNIT. Some states do not allow the disclaimer of liability for incidental or

consequential damages, so the above disclaimer may or may not apply to

you. This warranty gives specific legal rights, and you may also have rights,

which vary from state to state.

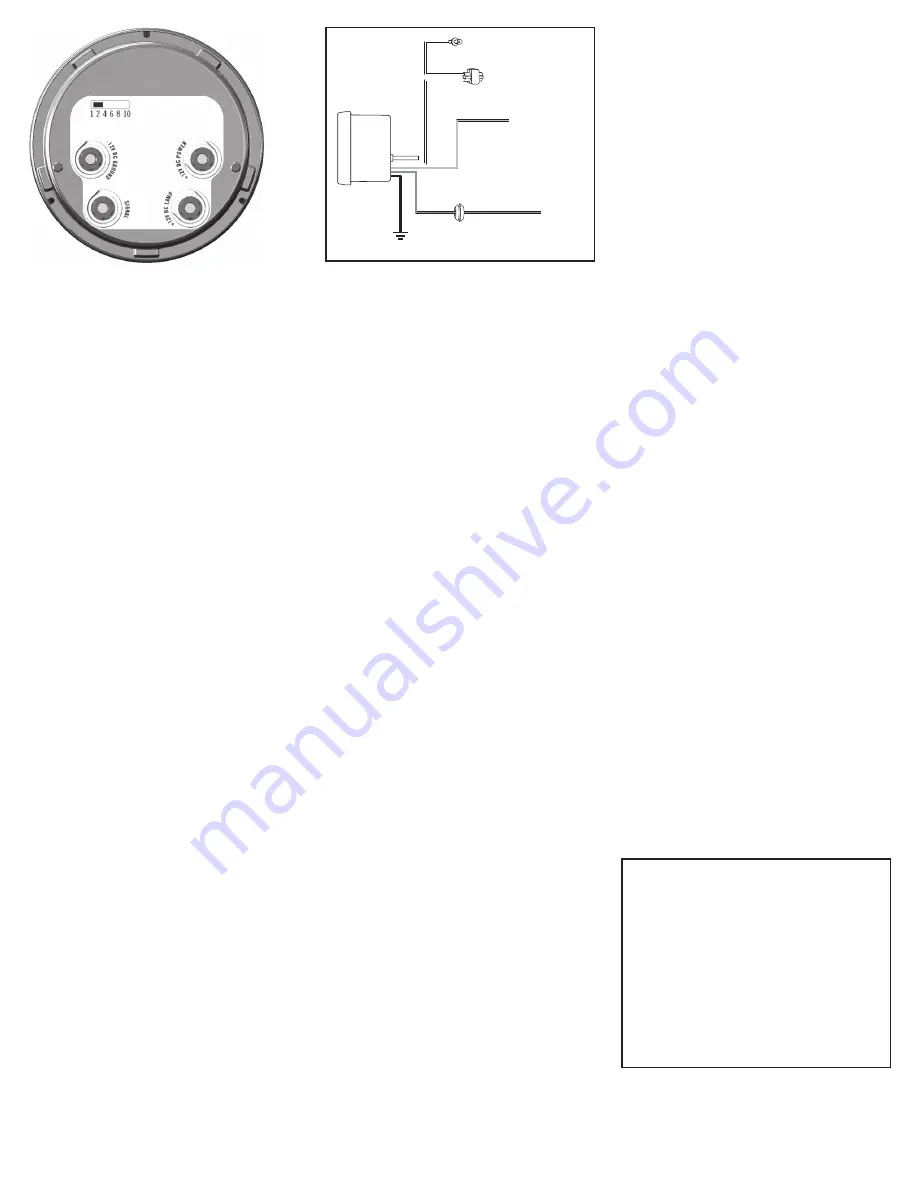

SWITCHED

+12V

SEE SIGNAL

POST CONNECTION

WIRE

SPLICE

TO DIMMER

SWITCH

LIGHT

WIRE

LAMP INSTRUMENT

GROMMET

WIRE

TO GND

GND

WIRE

SIGNAL

WIRE

+12V

ELECTRICAL CONNECTIONS

CAUTION

For your own personal safety, and to prevent possible

damage to the electrical system of your vehicle during

the installation, disconnect the negative (-) battery cable.

Reconnect this cable after installation is complete. Do

not route wires along or against sharp edges, hot engine

surfaces, or near spark plug wires. If needed, drill a 3/8”

hole in the firewall for the grommet (included).

1. Attach wires to tachometer as required.

NOTE:

Use # 18 or # 20 AWG stranded automotive

primary wire.

2. Thread wires through female nut (2), cup (1), bracket

(4 or 5) and male nut (3). Note: At this point, items 1,

2, 3 and 4 or 5 should have been preassembled.

3. Leave tachometer out of the cup for now.

SIGNAL POST CONNECTION AND CYLINDER

SELECTION

The Cylinder Selector Switch is located on the back of the

tachometer. The factory setting is 8-cylinders. Change

the setting if necessary.

The 4, 6, 8, and 10-cylinder settings are most common

for all distributor equipped engines and Distributorless

Ignition Systems (DIS) with a tachometer output lead.

The 2-cylinder setting is designed for 2-cylinder engines and

DIS systems without a tachometer output lead that allow

access to the driver wires from the vehicle computer

to the ignition module.

The 1-cylinder setting is used with single cylinder engine

vehicles and in conjunction with the

CP7560

Tach Signal

adapter.

The

CP7560

Tach Signal Adapter (sold separately)

senses current pulses in the wire that su12 volts

to the ignition coil primary windings or fuel injector and

converts the pulses to a signal that is understood by the

tachometer. The

CP7560

Tach Signal Adapter is required

to connect the tachometer to Coil On Plug ignition systems

and to diesel engines with electronic injection.

DISTRIBUTOR EQUIPPED ENGINES

Connect the SIGNAL tachometer post to the negative

(-) side of the ignition coil. This terminal may be referred

to as the TACH, TACH TEST, DEC, or ECU terminal.

Set the Cylinder Selection switch on the back of the

tachometer to match the number of cylinders in the

engine.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES WITH A TACHOMETER OUTPUT LEAD

Connect the SIGNAL tachometer post to the vehicle‘s

tachometer output lead.

Set the Cylinder Selection switch on the back of the

tachometer to match the number of cylinders in the

engine.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES WITHOUT A TACHOMETER OUTPUT

LEAD

If your vehicle’s DIS ignition system does not have a

tachometer output lead but allows access to the driver

wires from the vehicle computer to the ignition module,

connect the

SIGNAL

tachometer post to one of the

driver wires.

Set the Cylinder Selection switch on the back of the

tachometer to the 2-cylinder position regardless of

the number of cylinders in the engine.

MULTIPLE SPARK DISCHARGE IGNITION SYSTEM

EQUIPPED ENGINES

For Multiple Spark Discharge ignition systems, connect

the

SIGNAL

tachometer post only to the tachometer

output terminal on the ignition module. Do NOT connect

to the ignition coil.

Set the Cylinder Selection switch on the back of

the tachometer to match the number of cylinders

in the engine.

COIL ON PLUG IGNITION SYSTEM EQUIPPED

ENGINES

To connect the tachometer to these engines you need

to purchase the

CP7560

Tach Signal adapter. Follow

instructions included with the adapter to hook up wires

and to set the Cylinder Selection switch.

DIESEL ENGINES WITH ELECTRONIC INJECTION

To connect the tachometer to these engines you need to

purchase the

CP7560

Tach Signal adapter. Follow instruc-

tions included with the adapter to hook up wires and to set the

Cylinder Selection switch.

-12V DC GROUND, +12V DC POWER, AND 12V

DC LAMP POST CONNECTIONS

ALL VEHICLE SYSTEMS

1. Connect the post labeled

-12V DC GROUND

to the

negative (-) battery terminal, or a clean unpainted

chassis ground using a ring terminal or other suit-

able means.

2. Connect the post labeled

+12V DC POWER

to any

vehicle harness wire which is energized with battery

voltage, ONLY when the ignition key is in the ON

(RUN) position, NOT OFF OR ACCESSORIES.

3. Connect the post labeled

12V DC LAMP

to the

instrument panel lighting circuit that is controlled by

the instrument panel dimmer control.

Some vehicles (typically imported) wire the dimmer

control into the ground side of the instrument panel

lighting circuit, as opposed to the more conventional

“hot” or 12-volt side. In vehicles which use this circuit,

connect the

12V DC LAMP

post to a circuit which is

energized by the headlamp switch.

INSTALLING TACHOMETER IN CUP

1. Place tachometer in cup. Gently pull wires out, so

they would not be jammed between the cup and

tachometer.

2. Secure tachometer in cup using #8 lock washers

(6) and #8-32 acorn nuts (7). Turn acorn nuts down

finger-tight and, with a wrench or nut driver, tighten an

additional 1/2 turn. DO NOT OVER TIGHTEN.

3. Position cup as desired and tighten male nut (3).