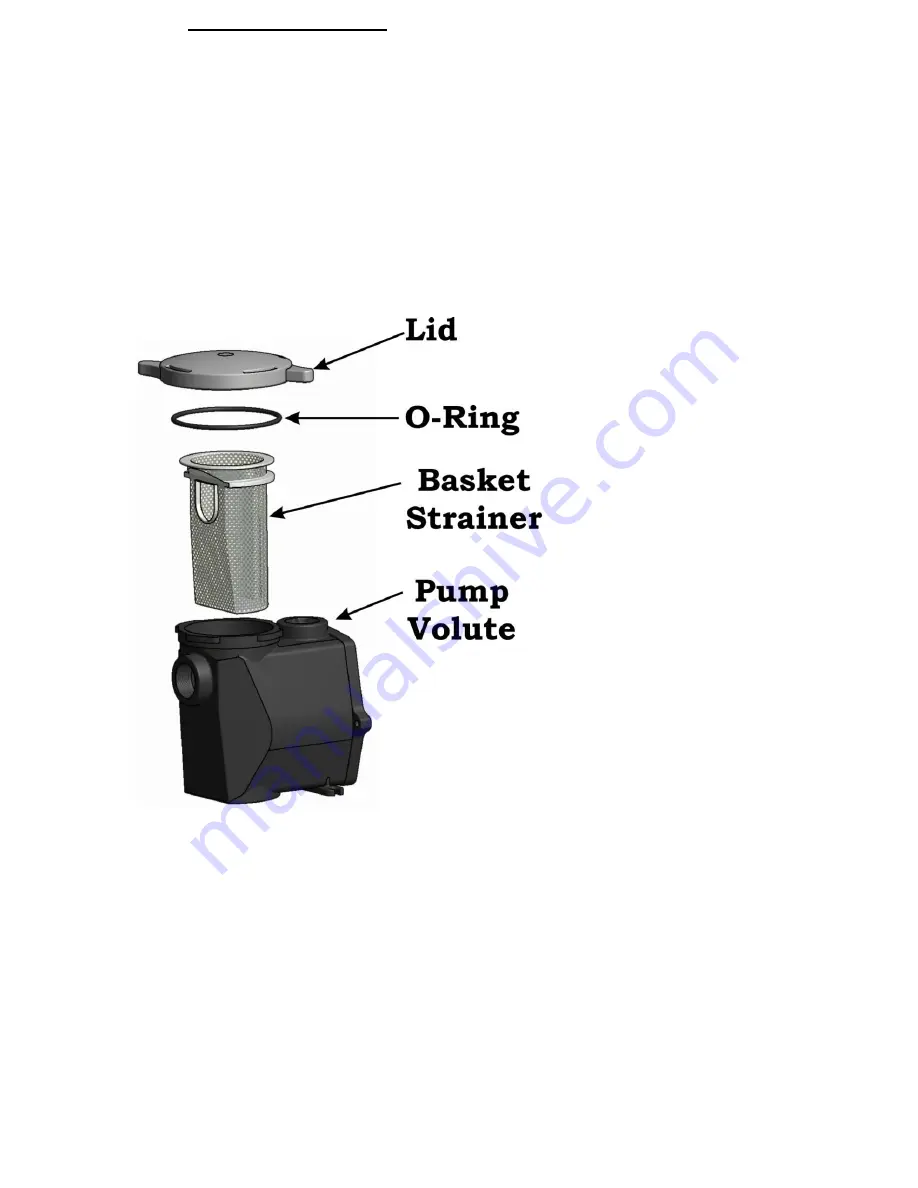

3.4 Pump Strainer Basket

This pump has a basket strainer, sometimes called a “Hair and Lint Pot” located in the front section of the pump

volute. Inside this chamber is a basket which must be kept clean of leaves and debris at all times. View the

basket through the “See-Through Lid” to inspect for various accumulations of trash. Regardless of the length of

time between filter cleaning, it is most important to visually inspect the basket at least once a week. A dirty

basket will reduce the efficiency of the filter and also put an abnormal stress on the pump motor which could

result in failure.

Warning:

Do not open the strainer pot if the pump fails to prime or if the pump has been operating

without water in the strainer pot. Pumps operated in these circumstances may experience a buildup

of vapor pressure and may contain scalding hot water. Opening the pump may cause serious

personal injury. In order to avoid the possibility of personal injury, make sure the suction and

discharge valves are open and strainer pot temperature is cool to the touch, then with extreme

caution, you can open the strainer lid. Do not open the strainer pot lid while the pump in in

operation.

Strainer Cleaning Procedure

1.

Turn off motor at the controller and then disconnect the solar array power to the controller.

2.

Relieve pressure in the system.

3.

Turn the lid in a counter-clockwise direction until it stops.

4.

Lift the lid and remove the basket.

5.

Put the debris from the basket into the trash and rinse out the gasket. If the basket is cracked, is should

be replaced.

6.

Replace the basket and fill the pump volute up to the inlet port with water.

7.

Clean the cover, O-ring and sealing surface of the pump volute. Grease the O-ring with Teflon or a

Silicone lubricant.

8.

Reinstall the lid.

9.

Make sure the4 lid O-ring is properly placed. Seat the lid then turn clockwise until

hand tight

only.

Do not over-tighten with tools. (Figure ?)

10.

Turn the power and then the controller “ON”.

11.

Open the manual air relief valve on top of the filter.

12.

Stand clear of the filter and start the pump.

13.

Bleed the air from the filter until a steady stream of water comes out. Close the manual air relief valve.

Summary of Contents for SCP series

Page 1: ......