Page 21

www.sunrotor.com

7.8

W

ELLHEAD

C

OMPONENTS

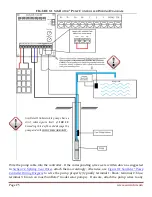

There are a few recommended methods to support the drop pipe. The first is a well seal. This is a

plate that fits on the top of the well casing. It provides a seal against contamination of the well, and it

supports the weight of the in-well assembly. In freezing climates, the wellhead must be located in a

heated building or in a covered well pit if no anti-freeze bleeder valve is used with the well seal.

The other method is the use of a pitless adapter. This is a fitting that allows your buried pipe to pass

through the well casing underground, without the need to build a covered pit. This system is used in

many conventional well systems and is available from local well pump suppliers. A well cap is

needed with this method.

The pitless adapter is ideal for freezing climates. It also provides protection against animals,

children, and vehicles that can damage exposed piping.

C

AUTION

:

The pump must be supported primarily by the drop pipe. The rope serves as a

safety measure in case of pipe breakage. The electrical cable must

NEVER

support any

weight.

The use of flexible conduit running from the top of the well seal or cap to the controller is

recommended. This will help against contamination and damage from animals. Please inform your

Authorized SunRotor

®

Dealer if the use of flexible conduit is planned, as additional parts are needed.

7.9

A

LLOWANCE FOR

P

IPE

S

TRETCH

Polyethylene (PE) drop pipe will stretch by about 1% of its original length. Rope will also stretch. To

keep it from bearing much weight, cut your rope 1% longer than the drop pipe.

The pump cable should

NEVER BEAR ANY WEIGHT

. Prevent this by making the length of your cable (the

portion below the wellhead) 1.5% longer than your drop pipe.

D

O NOT CUT IT YET

—

extra length is

needed to make a slack loop at the bottom, and to make connections at the surface. If the pump may

need to be lowered in the future, leave some extra cable rolled up at the wellhead, so no splicing will

be needed later.

W

ARNING

:

Never lift the pump by the electrical cable.

7.10

C

OPING WITH

D

IRTY

W

ATER

C

ONDITIONS

C

AUTION

:

SunRotor

®

solar pumps are clean water pumps, and are not meant to tolerate

water with extremely high sand or silt, or a high salinity, without increased wear and

tear.

D

O NOT

use this pump to develop or purge your well. Damage caused by pumping

in such conditions is

NOT

covered under the warranty.

Summary of Contents for Solar Pump

Page 1: ...SunRotor Solar Pump Installation and Resource Manual...

Page 36: ......