www.sunrotor.com

Page 22

The pump has a good resistance to occasional bits of sand and fine silt that normally occur in a water

well. However, as with any pump, extreme abrasive substances will cause accelerated wear and tear

on the rotor and stator, particularly if the water appears turbid.

To avoid pumping dirty water:

1.

Have the water well developed, purged, or otherwise improved by a drilling contractor.

2.

Temporarily install a larger AC pump (with a generator if necessary) to pump at a high flow

rate until silt is purged from the well.

If dirty water cannot be avoided:

1.

Use a smaller drop pipe (recommended no larger than ¾”) if or when possible. This will

maximize the velocity of water flow to allow particles to rise and leave the drop pipe.

2.

In case of a drilled well, place the pump as high as possible in the well. If the pump can be

placed higher than the perforations in the well casing, then all but the finest silt will probably

be avoided.

3.

Inspect and replace parts periodically (See

Section 11 Maintenance

).

4.

Monitor the situation by observing the accumulation of sediment in the storage tank.

7.11

W

ATER

S

ANITIZATION

If the well water will be used for household consumption, sanitize the well prior to pump

installation. This can be done with chlorine bleach or a dry chlorine compound poured down the

well just before (or just after) a pump is installed. Consult a local supplier or environmental health

authority for a recommended procedure.

8

P

UMP

I

NSTALLATION

8.1

A

SSEMBLING THE

D

ROP

P

IPE

,

C

ABLES

,

AND

S

AFETY

R

OPE

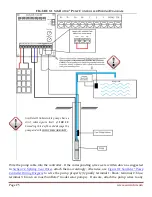

Tie the rope underneath the well seal or well cap. If the well cap does not have a place for a rope,

drill a hole in the casing and install an eye bolt. Prepare this detail

BEFORE

installation of the pump!

Do not leave the rope exposed to sunlight, as it can damage the outside of the casing.

When tying the rope to the pump, it’s important to make a knot that will not slip under tension (a

double half-hitch knot is recommended). If unsure of how to properly secure the pump to the rope,

please use the following method: before passing the rope through the eyelets, make a simple loop

knot 3 or 4 feet from the end of the rope, leaving it loose. Now pass the rope through the eyelets and

bring the end back up. Feed it up through the loop knot so that it doubles the loop and pull the knot

tight—it should feel secure with no tendency to slip.

8.2

M

ACHINE

I

NSTALLATION

If professionally equipped to install conventional AC submersible pumps, the same equipment can be

used for SunRotor

®

solar pumps. This method is used primarily for pumps with a set depth of 150 ft

Summary of Contents for Solar Pump

Page 1: ...SunRotor Solar Pump Installation and Resource Manual...

Page 36: ......