8

2 Mounting kit (part # SQ-RMK5) are required.

1 System kit (part # SQ-SK) is required.

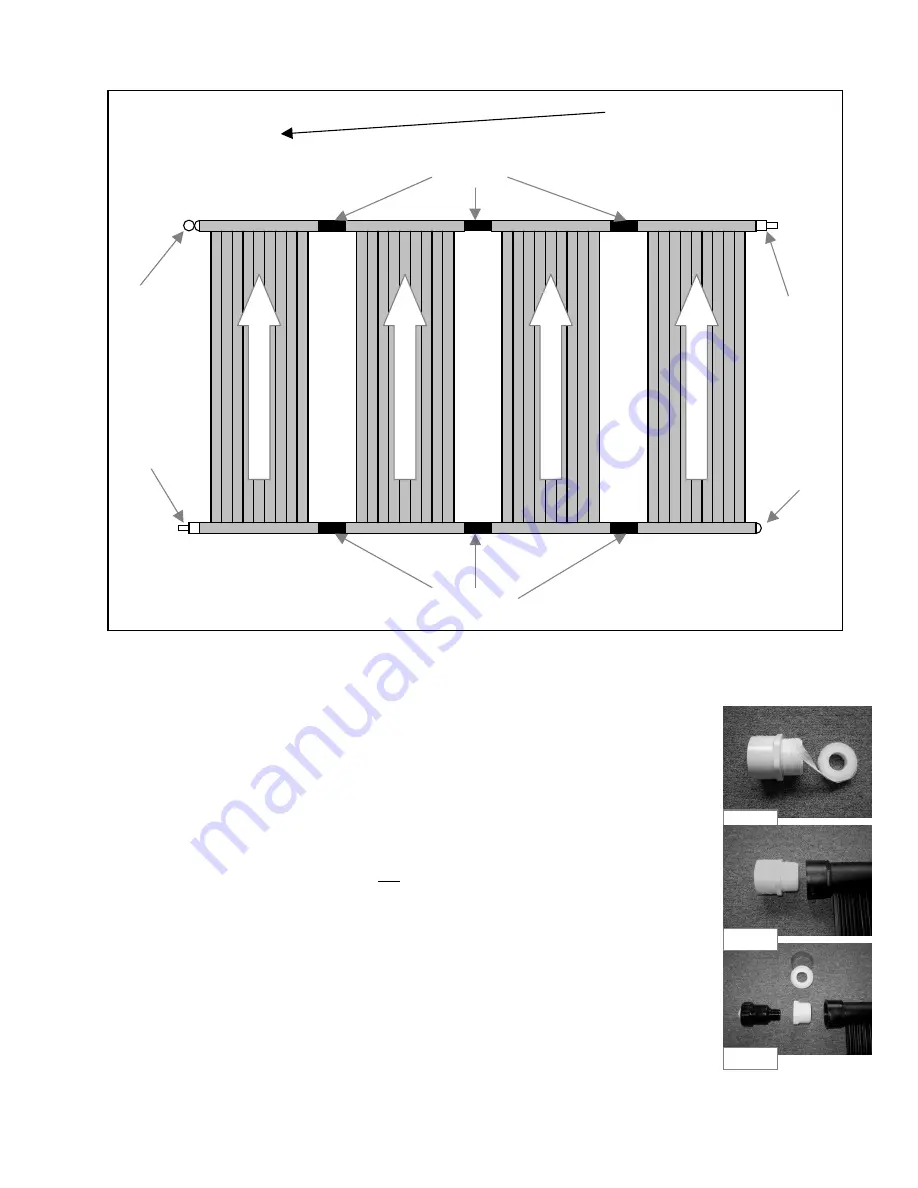

Diagram Step 3d

•

Using a utility knife cut rubber hose (

SK-FTG-J

) from each system in half. Make

sure you cut them as straight as possible. See Fig 3b-1. You should now have

rubbers that are 3 ¾" long.

•

Apply Teflon on one of the caps (

SK-FTG-F

). See Fig 3a-1.You only need 1 cap

for this type of installation.

•

Thread the cap into the panels as per Diagram Step 3d. Do not over tighten.

See Fig 3a-2

•

If you are using flexible piping to connect panels to your pump then Put "O" rings

(

SK-FTG-I

) on both combination adapters (

SK-FTG-D

) See Fig 3a-3. Thread both

combination adapters into the panels as per Diagram Step 3d. Do not over tighten.

See Fig 3a-4

OR

If you are using rigid piping to connect panels to your pump then apply Teflon on

both PVC adapters (

SK-FTG-N

). See Fig 3d-1. Thread both adapters into the

panels as per Diagram Step 3d. Do not over tighten. See Fig 3d-2.

•

Apply Teflon on reducer adapter (

SK-FTG-M

). Thread reducer adapter into the

panel as per diagram Step 3d. Do not over tighten. See Fig 3d-3.

•

Apply Teflon on vacuum relief valve (

SK-VRV

). Thread vacuum relief valve into

the reducer adapter. Do not over tighten. See Fig 3d-3.

Note: The vacuum valve assembly must be installed at the top of the panels as per diagram Step 3d.

3 d)

Cont.

V

a

cu

u

m

V

a

lv

e

C

o

m

b

in

a

ti

o

n

A

d

a

p

te

r

O

r

P

V

C

a

d

a

p

te

r

Outlet

C

o

m

b

in

a

ti

o

n

A

d

a

p

te

r

O

r

P

V

C

a

d

a

p

te

r

C

a

p

Rubber hose

3.75"

Inlet

Fig 3d-1

Fig 3d-3

A Minimum of 1 inch fall per 10 feet

Fig 3d-2

Rubber hose

3.75"