6

1 - Mounting kit (part # SQ-RMK5) is required

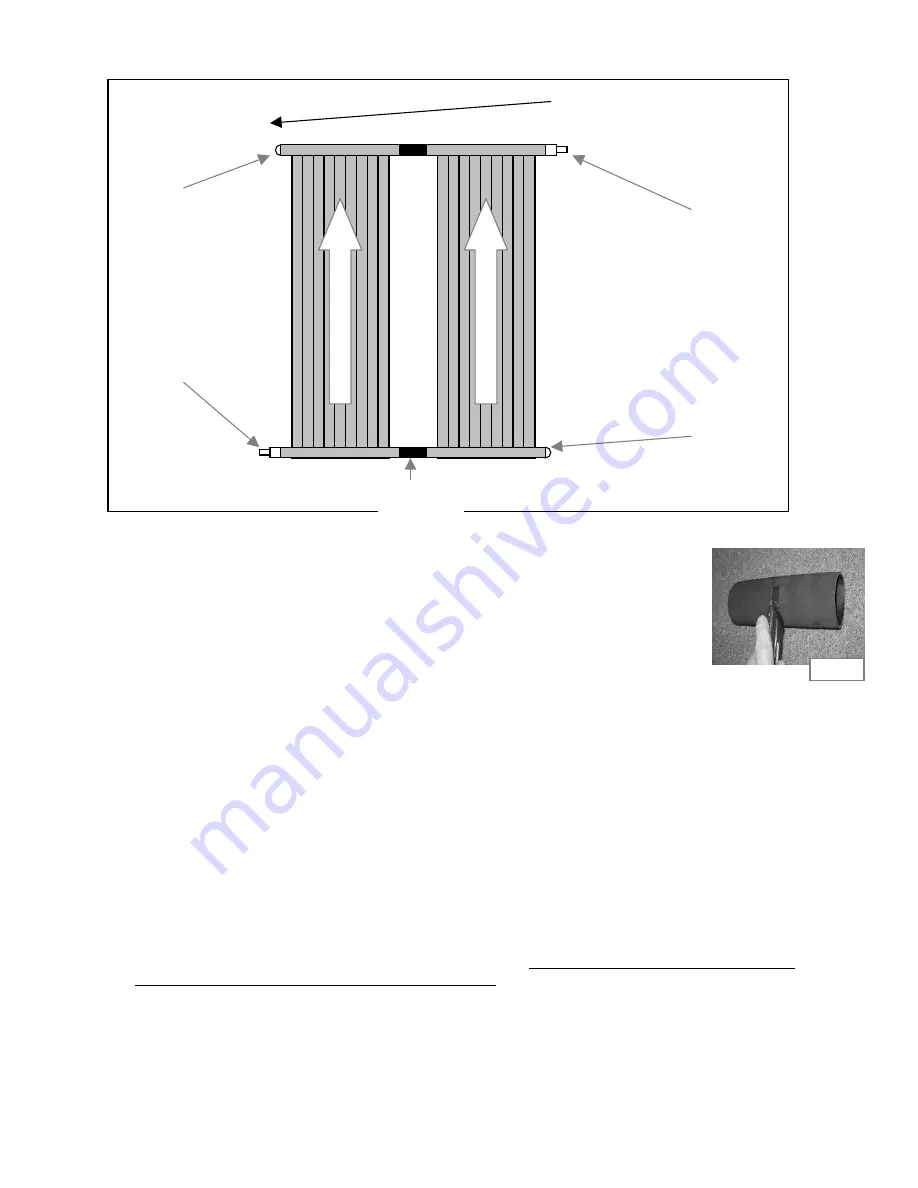

Diagram Step 3b

•

Using a utility knife or a hand saw, cut rubber hose (

SK-FTG-J

) in half. Make sure

you cut it as straight as possible. See Fig 3b-1. You should now have two rubbers

3 ¾" long.

•

Apply Teflon on two of the caps (

SK-FTG-F

). See Fig 3a-1.You only need 2 of the 4

caps for this type of installation.

•

Thread the 2 caps into the panels as per Diagram Step 3b. Do not over tighten.

See Fig 3a-2

•

Put "O" rings (

SK-FTG-I

) on both combination adapters (

SK-FTG-D

). See Fig 3a-3

•

Thread both combination adapters into the panels as per Diagram Step 3b.

Do not over tighten. See Fig 3a-4

•

Push the rubber hose you cut in half previously over the panel header as per Diagram

Step 3b. Slide a metal collar (

SK-FTG-L

) onto the rubber hose. Place metal collar

1

/

4

"

from edge and tighten collar with screwdriver. See Fig 3a-5. Repeat for other end of panel.

•

Slide another metal collar onto the rubber hose. Connect the 2 panels together by pushing

the rubber hose over the second panel header. Tighten metal collar to secure assembly.

See Fig 3a-6. Repeat for other end of panel.

•

Install mounting kits as per instructions included with them.

Panels must be installed with a slight

slope (minimum 1 inch per 10 feet) toward the inlet

. This will allow the panel to drain properly.

Note: The inlet must always be at the lower end of the panel and the outlet at the higher end of the panel.

3. c)

Installation: two systems on ground

.

C

o

m

b

in

a

ti

o

n

A

d

a

p

te

r

C

a

p

C

a

p

Rubber hose

3.75"

C

o

m

b

in

a

ti

o

n

A

d

a

p

te

r

Fig 3b-1

Inlet

Outlet

A Minimum of 1 inch fall per 10 feet