10

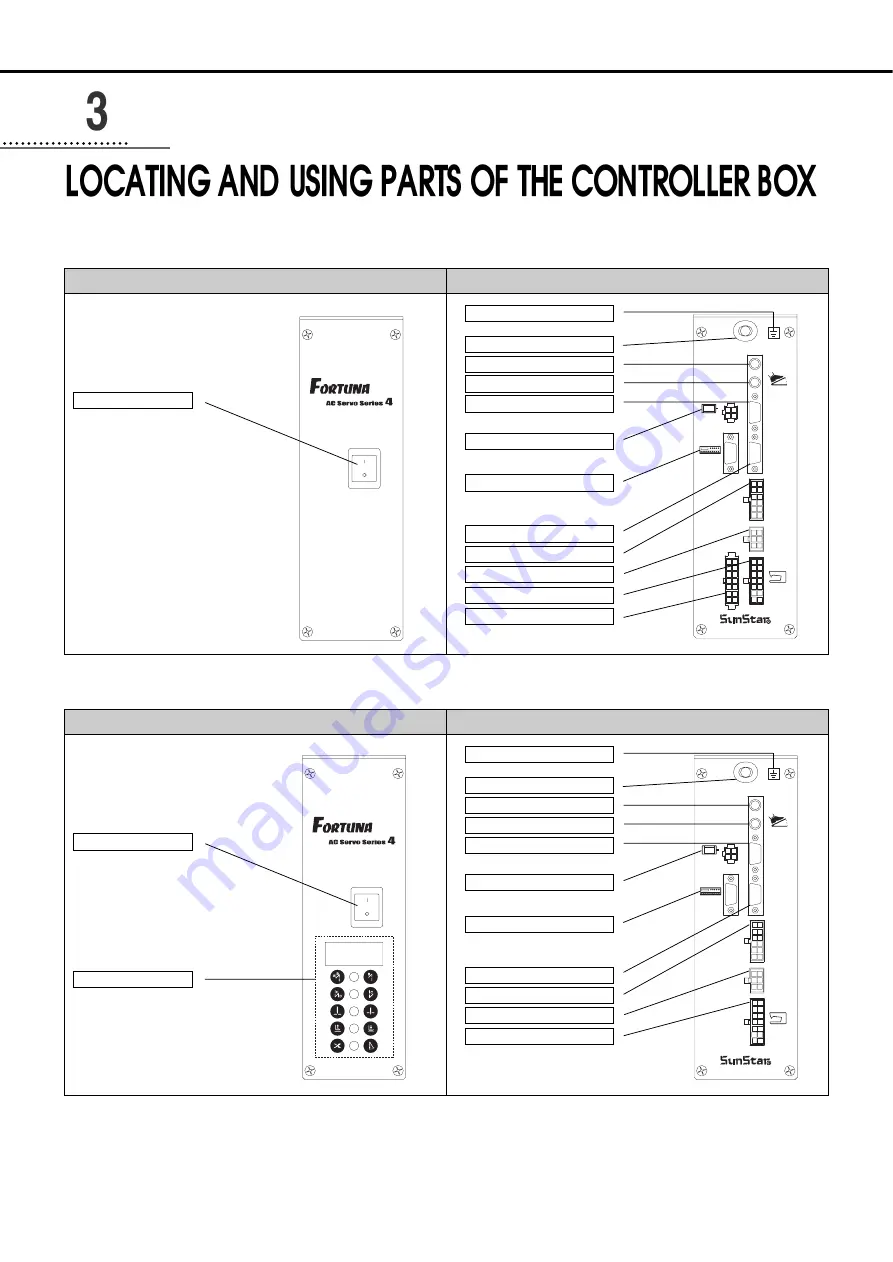

Control box back (Full Option Type)

Control box front (Full Option Type)

1) Front and back of control box

AC Power switch

AC Power Input Power Cable

Control box grounding part

Option 2 Connector

Pedal Connector

Encoder Connector

Motor Power Connector

Position Detector Connector

P/U Connector

Option 1 Connector

A/B Button Connector

Solenoids Connector

Option 3

Button

A/B

Option1

Option3

S/M

Synchro

P/U

Motor

Encoder

Pedal

Option2

SUNSTAR ELECTRIC CO., LTD.

Control box back (Economic Type)

Control box front (Economic Type)

AC Power switch

Simple Controller Board

AC Power Input Power Cable

Control box grounding part

Option 2 Connector

Pedal Connector

Encoder Connector

Motor Power Connector

Position Detector Connector

P/U Connector

Option 1 Connector

A/B Button Connector

Solenoids Connector

Button

A/B

Option1

S/M

Synchro

P/U

Motor

Encoder

Pedal

Option2

SUNSTAR ELECTRIC CO., LTD.

Summary of Contents for Fortuna IV Series

Page 2: ......

Page 4: ...USER S MANUAL ...