20

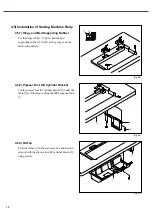

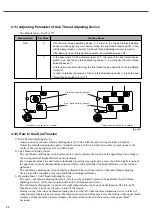

4.7) Trial run (Pedal operation)

4.8) Machine Stop Position Check

Press the reverse button

①

to make the needle to the highest and lowest position, and check the stop position of the

machine. When the stop position is improper, trimming may be faulty. In this case, the position of the magnetic

holder imbedded in the pulley should be corrected.

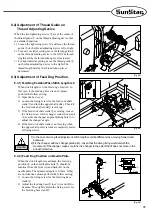

1) Press pedal lightly to the position of B to check if the

machine is operating low-speed sewing.

2) Press pedal to the position of C to check if the

machine is operating high-speed sewing.

3) Press pedal backward and forward. And then put the

pedal at neutral position of A to check if needle stops

lower than the upper surface of needle plate.(in case

that needle down stop is set)

4) When pressing pedal to the position of D(or pressing

pedal the position of to D and then replacing pedal

to the position of A), needle will stop higher than the

upper surface of needle plate after trimming.

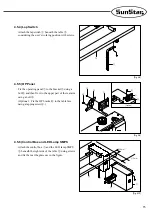

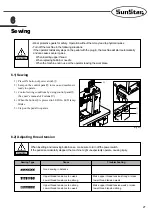

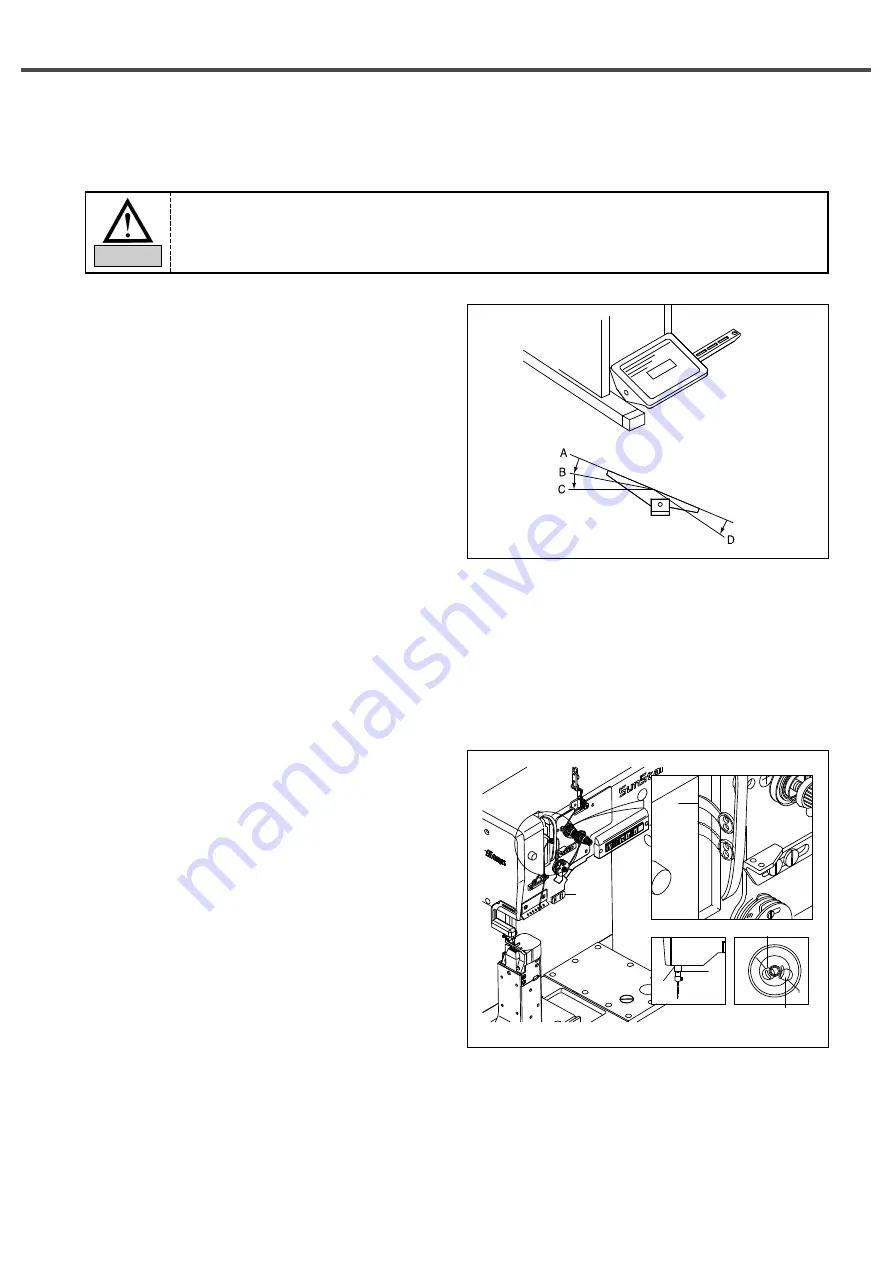

4.8.1) Check for up-stop position of needle

bar

The needle bar is at the highest stop position when

the thread take-up lever

②

stops at the highest

position. If their positions are not proper, adjust the

magnetic holder

③

embedded at the N.U punched

mark of the pulley left or right for correction.

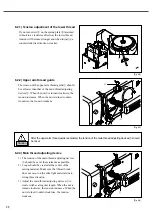

4.8.2) Needle Bar Lower Stop Position Check

The lower stop position of the needle bar is the

position where the punched mark

④

of the needle

bar meets the end of the needle bar frame

⑤

. When

the position is not correct, the position of the

magnetic holders

⑥

embedded in the N, D punched

marks of the pulley should be moved left or right for

readjustment.

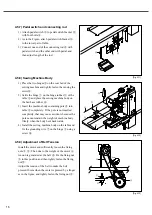

[Fig. 4-21]

[Fig. 4-22]

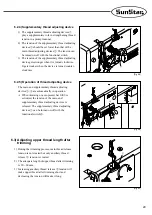

Make sure not to touch or press down parts that are operating or moving during operation. Failure to

follow the safety rules may result in physical injuries or mechanical damages.

Caution

①

⑤

④

③

N.U

N.D

⑥

②

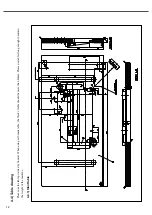

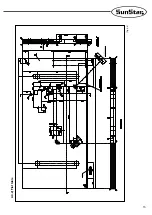

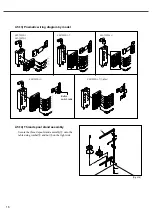

Summary of Contents for KM-1080 Series

Page 2: ......

Page 13: ...13 4 4 2 Flat table Fig 4 4 ...