28

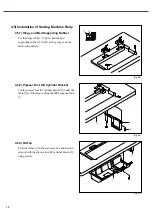

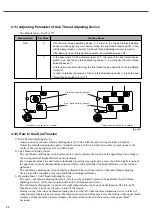

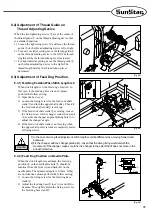

6.2.1) Tension adjustment of the lower thread

If you turn screw

②

on the spring plate

①

mounted

in hook in a clockwise direction, the lower thread

tension will become stronger and when turned in a

counterclockwise direction, weaker.

[Fig. 6-2]

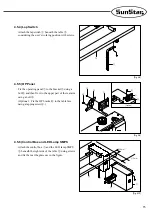

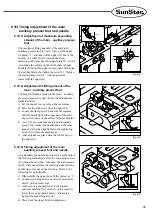

6.2.2) Upper arm thread guide

The tension of the upper arm thread guide

①

should

be set lower than that of the main thread adjusting

devices

②

. When the nut

③

is turned clockwise, the

tension increases. When the nut is turned counter-

clockwise, the tension weakens.

[Fig. 6-3]

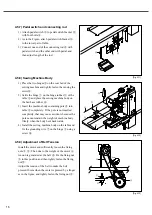

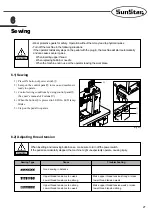

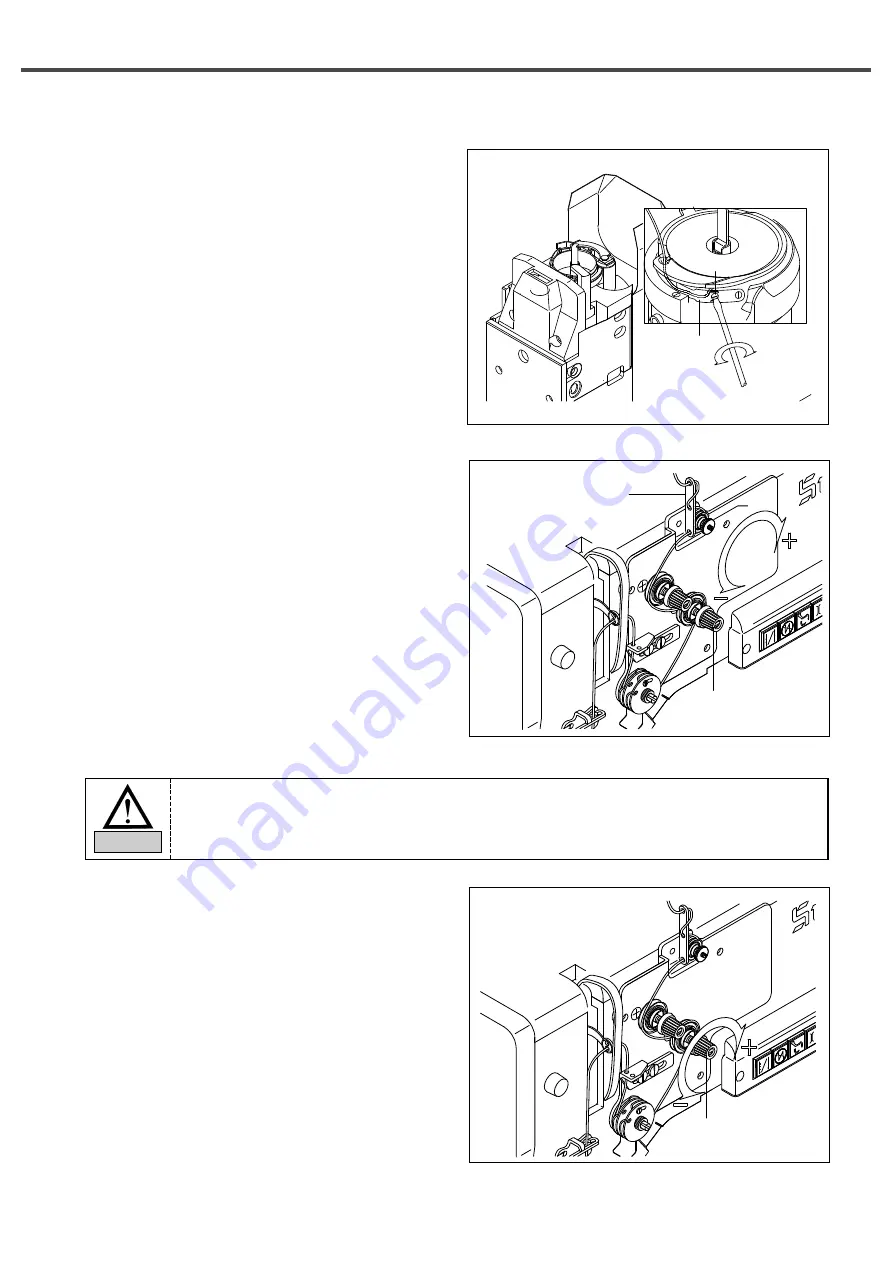

6.2.3) Main thread adjusting device

1) The tension of the main thread adjusting devices

①

should be set at the minimum as possible.

2) Loops should be created at the center of the

sewing material. Make sure that thread break

does not occur on the ultra light material due to

strong thread tension.

3) Adjust the main thread adjusting devices

①

to

create stitches at regular length. When the nut is

turned clockwise, the tension increases. When the

nut is turned counter-clockwise, the tension

weakens.

[Fig. 6-4]

①

②

After the upper arm thread guide is adjusted, the tension of the main thread adjusting devices

②

should

be reset.

Caution

①

③

②

①

Summary of Contents for KM-1080 Series

Page 2: ......

Page 13: ...13 4 4 2 Flat table Fig 4 4 ...