35

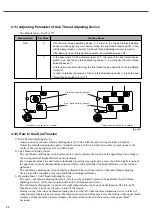

8.2) Adjustment of Thread Guide on

Thread Adjusting Device

When the two tightening screws

②

are at the center of

the thread guide

①

on the thread adjusting device, this

is a standard position.

1) Loosen the tightening screw

②

and move the thread

guide

①

on the thread adjusting device left or right.

2) For heavy material sewing, move the thread guide

①

on the thread adjusting device to the left (The thread

length held by the thread take-up lever increases).

3) For light material sewing, move the thread guide

①

on the thread adjusting device to the right (The

thread length held by the thread take-up lever

decreases).

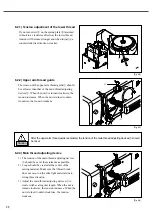

8.3) Adjustment of Feed Dog Position.

8.3.1) Feed Dog Position When Stitch Length is 0

When stitch length is 0, the feed dog's feed is 0. In

this case, if the feed dog's feed is not 0, please

perform the follow setting.

1) Open the bed cover.

2) Loosen the fixing screw for the feed rock shaft

crank

①

and turn the upper shaft pulley. Check if

the feed rock shaft crank

②

is moving.

3) If the feed rock shaft crank

②

is moving, loosen

the fixing screw for the changer connection crank

④

and use the changer angle adjusting hole

③

to

adjust the changer's angle.

4) If the feed rock shaft crank is not moving when

the upper shaft pulley is turned, completely fasten

all fixing screws.

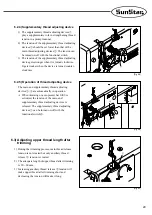

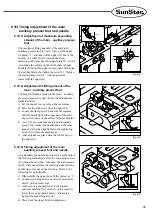

8.3.2) Feed Dog Position on Needle Plate

When the stitch length is maximum, the feed dog

position

②

in the needle plate hole

①

should be

identical from the front (A) and back (B) on the

needle plate. The minimum figure is 0.7mm. If they

are not identical, please perform the follow setting.

1) Loosen the fixing screw for the feed dog base

crank

③

.

2) Adjust the feed dog base

④

to set (A) and (B) to

be same. Then tightly fasten the fixing screw for

the feed dog base crank

③

.

①

①

(A)

(B)

②

②

④

③

0.7mm

[Fig. 8-4]

[Fig. 8-5]

[Fig. 8-6]

①

②

④

④

③

(X)

⑤

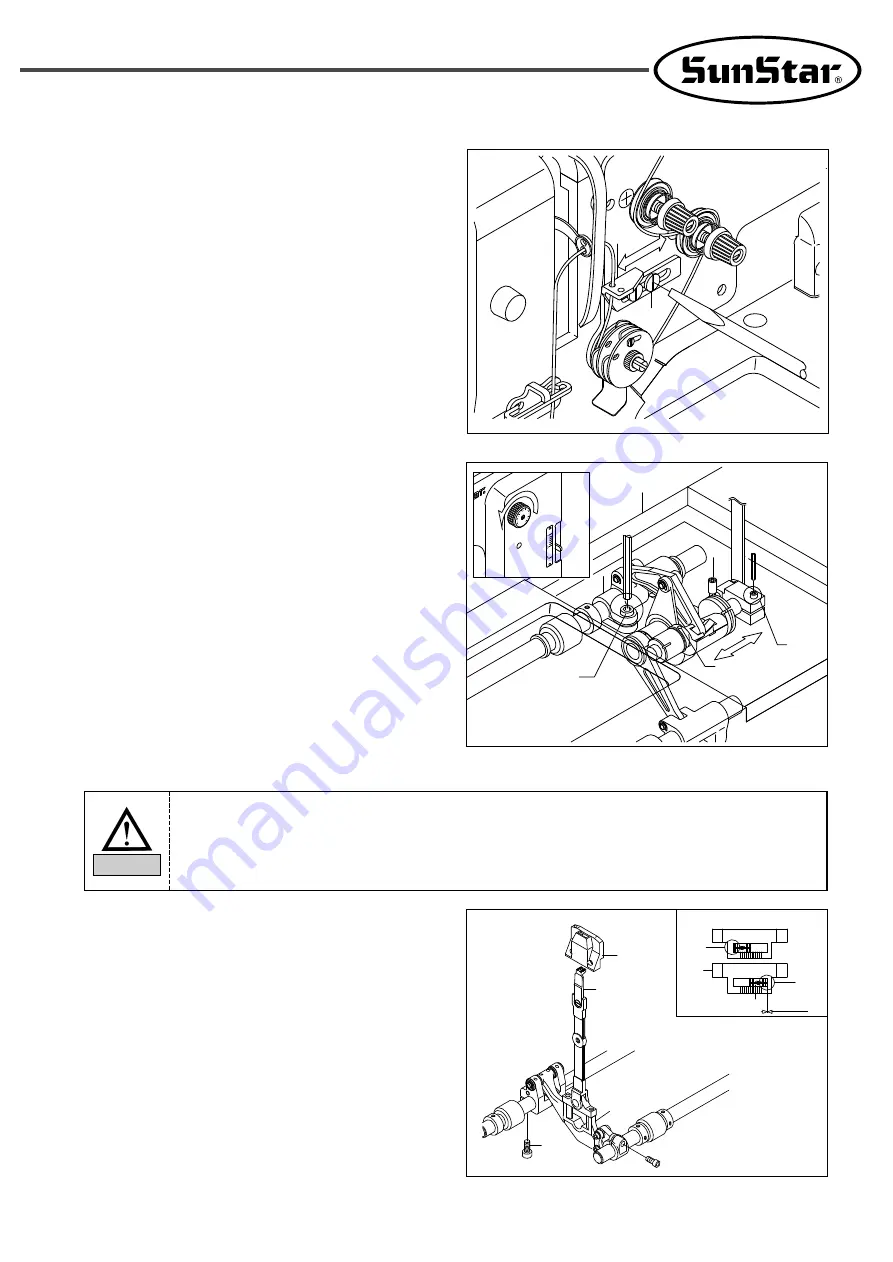

1) In the case of wrong feed adjustment, stitch length could be different when moving forward and

backward.

2) Fix the changer with the changer guide pin

⑤

. Given that the strong fixing would disturb the

movement of the changer, make sure to fix the changer to the extent that it does not move in the

arrow(X) direction.

Caution

①

②

Summary of Contents for KM-1080 Series

Page 2: ......

Page 13: ...13 4 4 2 Flat table Fig 4 4 ...