41

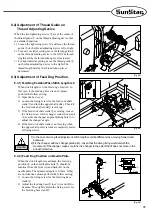

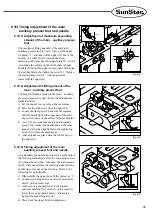

8.11.3) Adjustment of Trimmer Cam and Lever

Positions

The rotary movement of the fixed blade is

determined by the position of the trimmer cam

⑨

.

When the thread take-up lever is at the highest

position, the trimmer lever roller

⑧

touches the

highest tip of the trimmer cam

⑨

,

⑩

. However,

during sewing, the roller and the cam do not contact

each other and the distance between them is

maintained at 0.1mm. Adjustment can be made in the

following order:

1) Unfasten the trimmer cylinder block fixing

screws

①

,

②

.

2) Adjust the trimmer cylinder piston to place the

roller 1mm away from the lowest point of the

trimmer cam. Then fasten the fixing screws

①

,

②

.

3) Unfasten the trimmer cam fixing screws

③

,

④

,

⑤

.

4) Adjust the trimmer cam with the needle bar at the

lowest point. Arrange

⑥

,

⑦

,

⑧

in a straight line

and fasten the trimmer cam fixing screws

③

,

④

,

⑤

.

③

③

②

④

④

⑤

⑦

⑧

⑤

⑥

1mm

①

[Fig. 8-20]

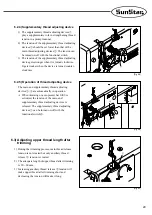

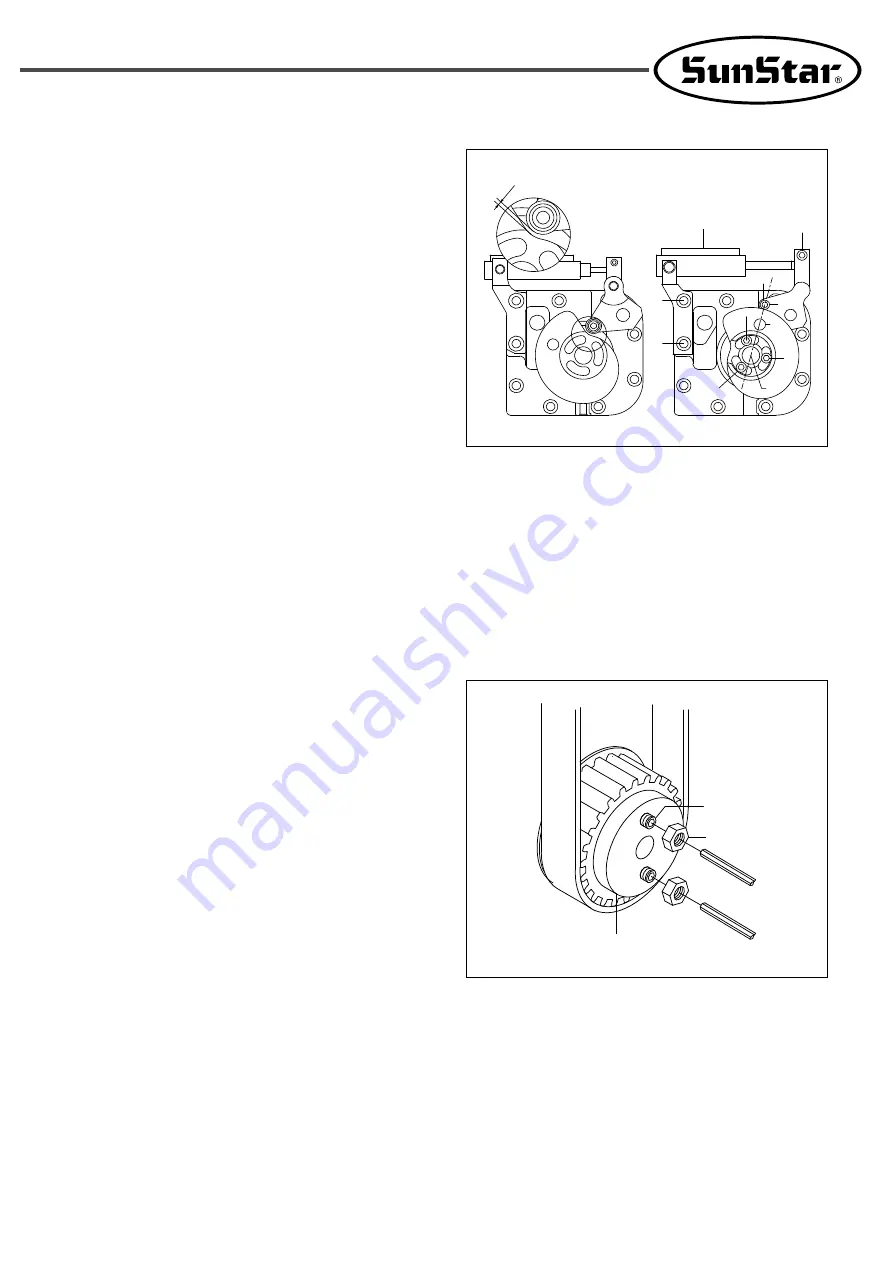

8.12) Safety Clutch

The safety device for the lower shaft timing pulley

②

is

to prevent hook damage caused by thread winding

around the hook or the setting disruption.

1) Slightly loosen two piston stopper screw nuts

③

.

2) When the two piston stopper screws

①

are turned

clockwise, it increases torque, and vice versa. After

torque adjustment, tightly fasten the nut

③

.

[Fig. 8-21]

③

②

①

Summary of Contents for KM-1080 Series

Page 2: ......

Page 13: ...13 4 4 2 Flat table Fig 4 4 ...